Preparation method of methyl 3, 3-dimethoxy propionate

A technology of methyl dimethoxypropionate and methyl acetate, applied in the chemical field, can solve the problems of low yield, high cost, complicated preparation process, etc., and achieve the effect of high yield, few reaction steps and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

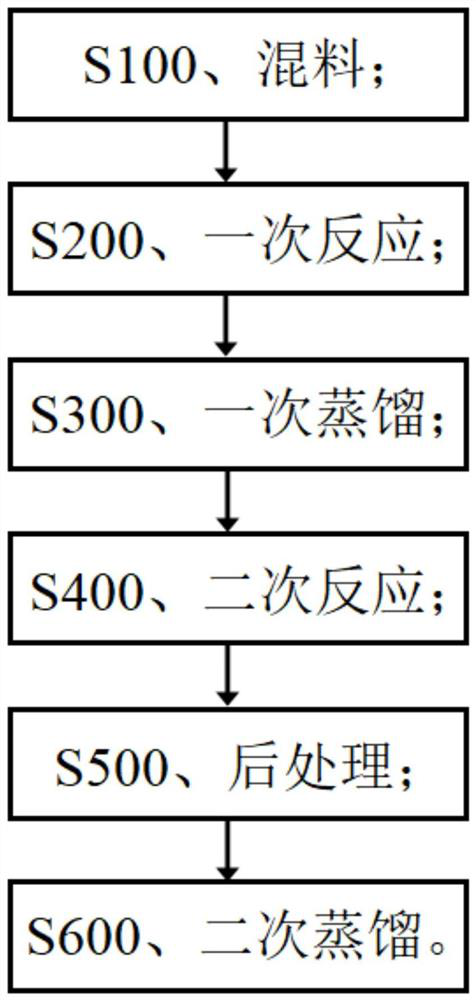

[0032] Refer to attached figure 1 , a preparation method of methyl 3,3-dimethoxypropionate in this embodiment, put 100.0g methyl acetate and 16.5g sodium methoxide into the autoclave, and then feed CO gas to 4.0MPa , the reaction temperature is at 60°C, and the CO pressure is controlled at 4.0MPa. After the reaction is over, the feed liquid is transferred to a distillation pot to evaporate excess methyl acetate. Slowly add 131.4g of 10% methanolic hydrogen chloride solution dropwise, and control the reaction temperature to 40°C. After post-treatment, concentration and distillation, 39.0g of methyl 3,3-dimethoxypropionate is obtained, with a purity of 96.8%. The rate is 85.2%. Under the action of strong base sodium alkoxide, methyl acetate makes the alpha carbon on methyl acetate form a carbanion, and then combines with carbon monoxide to form enol sodium salt after rearrangement. The enol sodium salt undergoes addition and substitution reactions with methanol in the presence...

Embodiment 2

[0034] Refer to attached figure 1 , a preparation method of methyl 3,3-dimethoxypropionate in this embodiment, put 200.0g methyl acetate and 16.5g sodium methoxide into the autoclave, and then feed CO gas to 3.5MPa , the reaction temperature is 50°C, and the CO pressure is controlled at 2.8-3.2MPa. After the reaction is completed, the feed liquid is transferred to a distillation pot to evaporate excess methyl acetate. Slowly add 109.3g of 10% hydrogen chloride methanol solution dropwise, the reaction temperature is 50°C, after post-treatment, concentration, distillation, to obtain 3,3-dimethoxypropionate methyl ester, 36.5g, purity 97.5%, yield 80.2%.

Embodiment 3

[0036] Refer to attached figure 1 , a preparation method of methyl 3,3-dimethoxypropionate in this embodiment, 300.0g methyl acetate and 16.5g sodium methoxide are put into the autoclave, and then CO gas is introduced to 3MPa, The reaction temperature is 50°C, and the CO pressure is controlled at 2.8-3.2MPa. After the reaction is completed, the feed liquid is transferred to a distillation pot to evaporate excess methyl acetate. Slowly add 131.4g of 10% hydrogen chloride methanol solution dropwise, the reaction temperature is 45°C, after post-treatment, concentration, distillation, to obtain 3,3-dimethoxypropionate methyl ester, 41.6g, purity 97.1%, yield 91.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com