Bio-based copolyester, preparation method and application thereof

A copolyester, bio-based technology, applied in the field of polymer material synthesis, to achieve the effects of enhancing water vapor barrier properties, improving heat resistance, and reducing chain segment mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

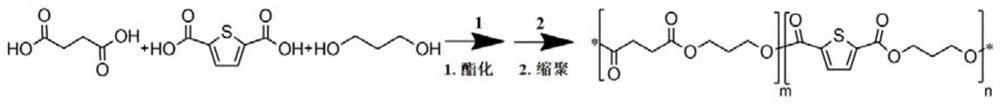

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a kind of bio-based copolyester, and its preparation method comprises:

[0041] (1) Add 2,5-thiophenedicarboxylic acid, dimethyl 1,4-butanedioate and 1,3-propanediol with a molar ratio of 7:3 into a 250mL three-necked flask, the alkyd (ester) ratio 1.2:1, then add zinc acetate with a total molar weight of 5‰ of 2,5-thiophenedicarboxylic acid and 1,4-dimethyl succinate monomer, and connect one end of the three-necked flask to nitrogen gas, and the other end to water separator and condenser , The middle port is connected with a mechanical stirring device, and then the three-necked flask is heated in an oil bath, the reaction temperature is 210° C., and the reaction time is 5 hours.

[0042] (2) After the reaction is completed, lower the temperature, then add zinc acetate with a total molar weight of 5‰ of 2,5-thiophenedicarboxylic acid and dimethyl 1,4-succinate, stir for a period of time, and then heat up to 230°C. The vacuum is below 50Pa, and ...

Embodiment 2

[0048] This embodiment provides a kind of bio-based copolyester, and its preparation method comprises:

[0049] (1) Add 2,5-thiophenedicarboxylic acid, 1,4-butanedioic acid and 1,3-propanediol with a molar ratio of 6:4 into a 250mL three-necked flask with an alkyd ratio of 1.1:1, three-necked One end of the flask is connected with nitrogen gas, the other end is connected with a water separator and a condenser, and the middle port is connected with a mechanical stirring device. Then the three-neck flask was placed in an oil bath and heated, the reaction temperature was 190° C., and the reaction time was 3 hours.

[0050] (2) After the reaction is completed, lower the temperature, and then add tetrabutyl titanate with a total molar weight of 0.5‰ of monomers of 2,5-thiophenedicarboxylic acid and 1,4-succinic acid. After stirring for a period of time, the temperature was raised to 230°C, and the vacuum was evacuated to below 50Pa, and the reaction was terminated after the obviou...

Embodiment 3

[0057] This embodiment provides a kind of bio-based copolyester, and its preparation method comprises:

[0058] (1) dimethyl 2,5-thiophenedicarboxylate, 1,4-butanedioic acid and 1,3-propylene glycol with a molar ratio of 5:5 are added to a 250mL three-necked flask, and the alkyd (ester) ratio is 1.1:1, then add dimethyl 2,5-thiophenedicarboxylate and antimony oxide with a total molar weight of 2‰ of 1,4-butanedioic acid monomers, connect one end of the three-necked flask to nitrogen gas, and the other end to a water separator and condenser, The middle port is connected with a mechanical stirring device. Then the three-necked flask was placed in an oil bath and heated, the reaction temperature was 200° C., and the reaction time was 4 hours.

[0059] (2) After the reaction is completed, the temperature is lowered, and antimony oxide with a total molar weight of 2‰ of monomers of 2,5-thiophenedicarboxylate and 1,4-succinic acid is added. After stirring for a period of time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com