Preparation method of nitrile group-containing epoxy resin toughening agent

A technology of epoxy resin and toughening agent, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., and can solve the problems of toughened epoxy resin molding process difficulties, complicated and cumbersome processing procedures, and material performance degradation. , to achieve the effect of strengthening interaction and compatibility, improving toughening effect, and low viscosity of toughening agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] A preparation method of an epoxy resin toughening agent containing a nitrile group, which is realized through the following technical scheme: Step 1: by weight, respectively weigh 50 parts of 2-methyl-1,5-pentanediamine, 45.7 parts of acrylonitrile , then add acrylonitrile dropwise to a container containing 2-methyl-1,5-pentanediamine, stir and react at room temperature for 1 hour, then stir and react at 80°C for 2 hours to obtain acrylonitrile-modified fatty amine Step 2: by weight, weigh 45 parts of acrylonitrile-modified aliphatic amine and 46 parts of 1,6 hexanediol diacrylate, stir and react at room temperature for 1 hour, then stir and react at 80°C for 2 hours to obtain A toughening agent for epoxy resin containing nitrile groups.

[0011] The prepared epoxy resin toughener had a viscosity of 110 centipoise at 23°C.

Embodiment 2

[0013] A preparation method of an epoxy resin toughening agent containing nitrile groups, realized by the following technical scheme: step 1: by weight, respectively weigh 60 parts of isophorone diamine, 37.38 parts of acrylonitrile, and then acrylonitrile Add it dropwise into a container containing isophoronediamine, stir and react at room temperature for 2 hours, then stir and react at 80°C for 2 hours to obtain acrylonitrile-modified fatty amine; step 2: weigh in parts by weight 45 parts of acrylonitrile-modified aliphatic amines and 36.8 parts of 1,6 hexanediol diacrylate were stirred and reacted at room temperature for 2 hours, and then stirred and reacted at 80°C for 2 hours to obtain a nitrile group-containing epoxy resin. Toughener.

[0014] The prepared epoxy resin toughener had a viscosity of 139 centipoise at 23°C.

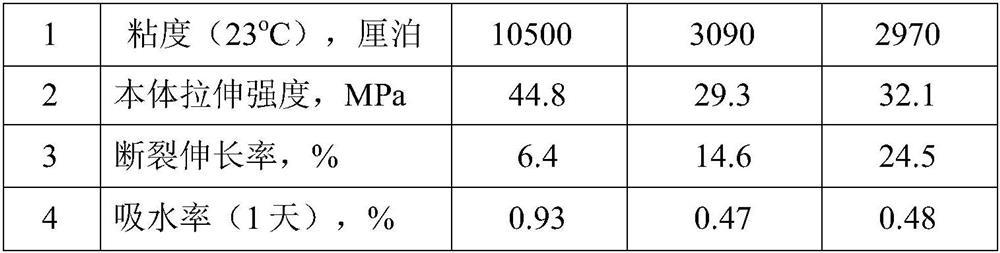

[0015] performance test results

[0016] Prepare the epoxy adhesive according to the following recipe:

[0017] Blank example: 100 parts by weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com