Environment-friendly polyvinyl chloride optical cable sheathing material and preparation method thereof

A polyvinyl chloride and optical cable technology, which is applied in the field of environmental protection polyvinyl chloride optical cable sleeve and its preparation field, achieves the effects of simple production process, low shrinkage and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

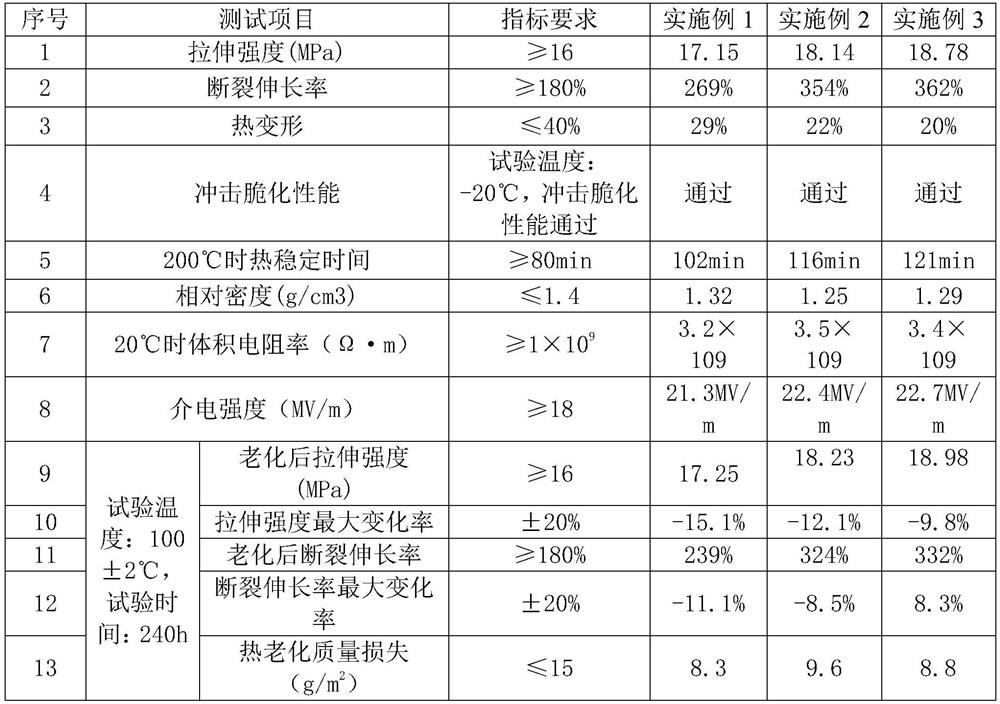

Examples

Embodiment 1

[0027] 1.1 Recipe

[0028] The environmentally friendly polyvinyl chloride optical cable sheathing material for indoor communication optical cables prepared in Example 1 is mainly composed of the following raw materials in parts by weight:

[0029] PVC resin: 40 parts, calcium carbonate: 40 parts, POP: 8 parts, plasticizer: 5 parts, lubricant: 3 parts, acrylate copolymer: 4 parts, stabilizer: 4 parts, pigment: 0.3 parts, Flame retardant: 7 parts, antioxidant: 0.2 parts, rodent repellent: 0.6 parts.

[0030] Among them, PVC resin is SG3 type resin and SG4 type resin, and the weight ratio is 1:1;

[0031] Among them, the plasticizer is chlorinated paraffin and DOTP, and the weight ratio is 1:1;

[0032] Among them, the lubricant is PE wax and PETS, and the weight ratio is 1:1;

[0033] Among them, the acrylate copolymer is a copolymer of methyl acrylate and acrylate, a copolymer of methyl methacrylate and acrylate, and the weight ratio is 1:2;

[0034] Among them, the stabil...

Embodiment 2

[0042] 2.1 Recipe

[0043] The special environment-friendly polyvinyl chloride optical cable sheathing material for indoor communication optical cables prepared in Example 2 is mainly composed of the following raw materials in parts by weight:

[0044] PVC resin: 50 parts, calcium carbonate: 30 parts, POP: 10 parts, plasticizer: 5 parts, lubricant: 3 parts, acrylate copolymer: 4 parts, stabilizer: 4 parts, pigment: 0.3 parts, Flame retardant: 8 parts, antioxidant: 0.3 parts, rodent repellent: 0.6 parts.

[0045] Among them, PVC resin is SG3 type resin and SG4 type resin, and the weight ratio is 1:1;

[0046] Among them, the plasticizer is chlorinated paraffin and DOTP, and the weight ratio is 1:1;

[0047] Among them, the lubricant is PE wax and PETS, and the weight ratio is 1:1;

[0048] Among them, the acrylate copolymer is a copolymer of methyl acrylate and acrylate, a copolymer of methyl methacrylate and acrylate, and the weight ratio is 1:2;

[0049] Among them, the s...

Embodiment 3

[0057] The environmentally friendly polyvinyl chloride optical cable sheathing material for indoor communication optical cables prepared in Example 3 is mainly composed of the following raw materials in parts by weight:

[0058] PVC resin: 60 parts, calcium carbonate: 40 parts, POP: 10 parts, plasticizer: 5 parts, lubricant: 3 parts, acrylate copolymer: 5 parts, stabilizer: 5 parts, pigment: 0.3 parts, Flame retardant: 10 parts, antioxidant: 0.5 parts, rodent repellent: 0.6 parts.

[0059] Among them, PVC resin is SG3 type resin and SG4 type resin, and the weight ratio is 1:1;

[0060] Among them, the plasticizer is chlorinated paraffin and DOTP, and the weight ratio is 1:1;

[0061] Among them, the lubricant is PE wax and PETS, and the weight ratio is 1:1;

[0062] Among them, the acrylate copolymer is a copolymer of methyl acrylate and acrylate, a copolymer of methyl methacrylate and acrylate, and the weight ratio is 1:2;

[0063] Among them, the stabilizer is rare earth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com