Anti-static and wear-resistant non-woven fabric

A non-woven, wear-resistant technology, applied in the direction of wear-resistant fibers, non-woven fabrics, textiles and papermaking, etc., can solve the problem of poor wear resistance and mechanical properties of non-woven fabrics, weak fiber adhesion, easy to produce Static electricity and other problems, to achieve the effect of promoting healing, not easy to static electricity, and strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

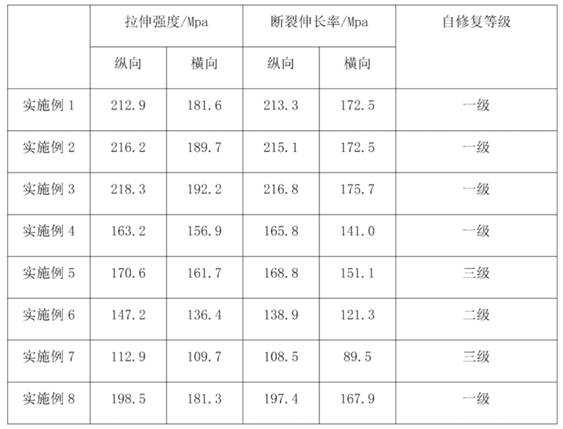

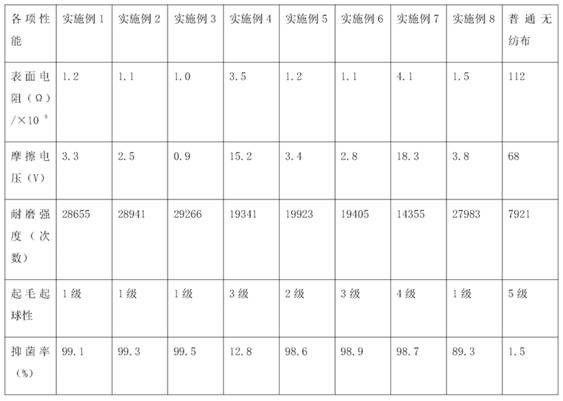

Examples

Embodiment 1

[0049] S1. Preparation of filler:

[0050] A. Dissolve zirconium tetrachloride and 2-aminoterephthalic acid in N,N-dimethylformamide, add acetic acid and ultrasonically disperse for 30 minutes to obtain solution A;

[0051] B. Silver nitrate and polyvinylpyrrolidone are placed in ethylene glycol, stirred and dissolved to obtain solution B;

[0052] C. Preheat the ferric chloride solution at 120°C for 5 minutes to obtain solution C;

[0053] D. Mix solution C and solution A evenly and pump into solution B at a speed of 400 μL / min, stir magnetically for 1 hour, filter and wash to obtain filler;

[0054] S2. Preparation of non-woven fabric substrate:

[0055] A. Mix polyethylene terephthalate and polytrimethylene terephthalate, melt, add filler, isophorone diisocyanate, polyrotaxane, dibutyltin dilaurate, stir for 3 hours, and Put it in a twin-screw extruder to melt and extrude it, spin and cool to obtain fiber filaments;

[0056] B. Stretch the filaments at 125°C to 2.5 time...

Embodiment 2

[0064] S1. Preparation of filler:

[0065] A. Dissolve zirconium tetrachloride and 2-aminoterephthalic acid in N,N-dimethylformamide, add acetic acid and ultrasonically disperse for 35 minutes to obtain solution A;

[0066] B. Silver nitrate and polyvinylpyrrolidone are placed in ethylene glycol, stirred and dissolved to obtain solution B;

[0067] C. Preheat the ferric chloride solution at 130°C for 6 minutes to obtain solution C;

[0068] D. Mix solution C and solution A evenly and pump into solution B at a speed of 500 μL / min, stir magnetically for 2 hours, filter and wash to obtain filler;

[0069] S2. Preparation of non-woven fabric substrate:

[0070] A. Mix polyethylene terephthalate and polytrimethylene terephthalate, melt, add filler, isophorone diisocyanate, polyrotaxane, dibutyltin dilaurate, stir for 5 hours, and Put it in a twin-screw extruder to melt and extrude it, spin and cool to obtain fiber filaments;

[0071] B. Stretch the filaments at 140°C to 3 times...

Embodiment 3

[0079] S1. Preparation of filler:

[0080] A. Dissolve zirconium tetrachloride and 2-aminoterephthalic acid in N,N-dimethylformamide, add acetic acid and ultrasonically disperse for 40 minutes to obtain solution A;

[0081] B. Silver nitrate and polyvinylpyrrolidone are placed in ethylene glycol, stirred and dissolved to obtain solution B;

[0082] C. Preheat the ferric chloride solution at 140°C for 8 minutes to obtain solution C;

[0083] D. Mix solution C and solution A evenly and pump into solution B at a speed of 600 μL / min, stir magnetically for 3 hours, filter and wash to obtain filler;

[0084] S2. Preparation of non-woven fabric substrate:

[0085] A. Mix polyethylene terephthalate and polytrimethylene terephthalate, melt, add filler, isophorone diisocyanate, polyrotaxane, dibutyltin dilaurate, stir for 6 hours, and Put it in a twin-screw extruder to melt and extrude it, spin and cool to obtain fiber filaments;

[0086] B. Stretch the filaments at 155°C to 3.5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com