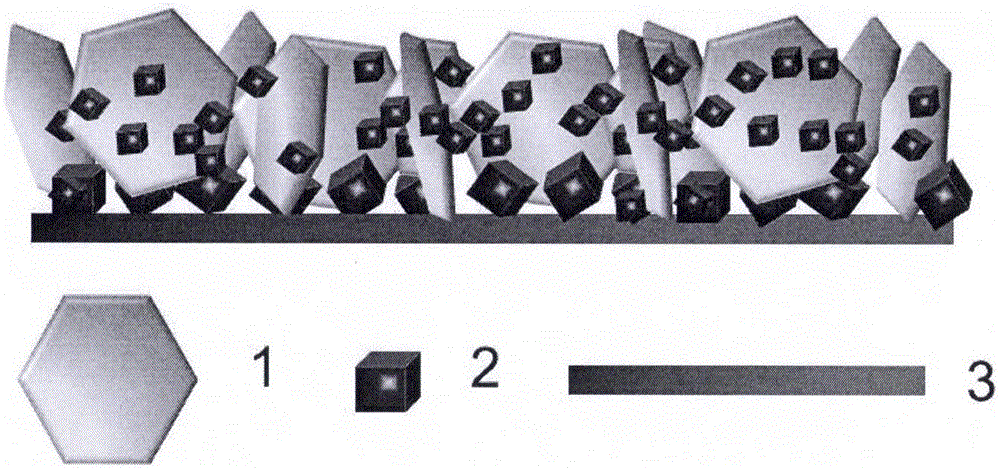

High-sensitivity electrode material for glucose non-enzymatic sensor and preparation method of electrode material

A glucose sensor and high-sensitivity technology, applied in the field of glucose detection, can solve the problems of complicated steps, high equipment requirements, long hydrothermal method, etc., and achieve the effects of simple method, low equipment cost, and short preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

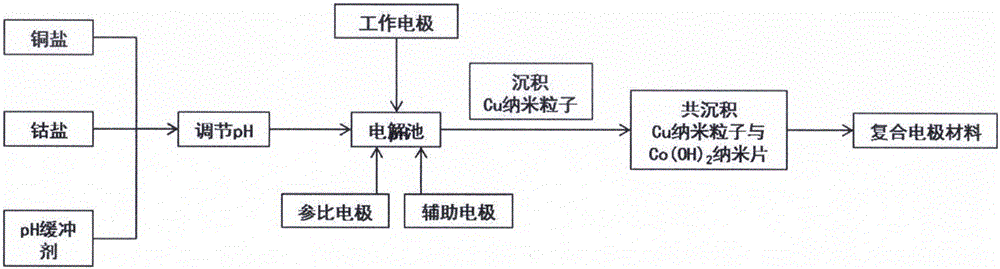

Method used

Image

Examples

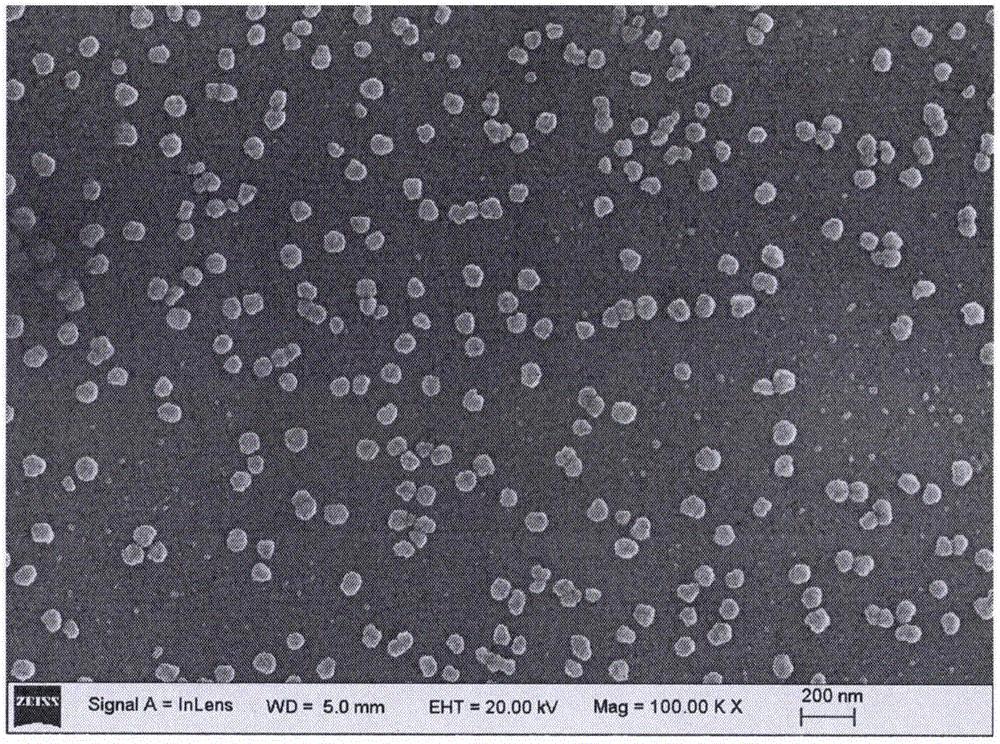

Embodiment 1

[0039] First configure 20mM (NH 4 ) 2 SO 4 -10mM CuSO 4 -10mM CoSO 4 Mix the solution, then wash with 1M H 2 SO 4 Adjust the pH to 4 as the electrolyte for later use, and pass through argon gas for 30 minutes to remove dissolved oxygen. Two pieces of ruthenium-plated titanium are used as auxiliary anodes, and one piece of nickel foam is used as the working electrode (cathode), placed in parallel in the order of anode-cathode-anode, adding the prepared electrolyte, and applying 25mA·cm -2 The electric current is deposited for 300s. After the end of the electrodeposition process, the electrodes were quickly taken out, washed with water, and then dried for later use. After the composite electrode material is welded and packaged with wires, it is used as the working electrode of the glucose sensor, and the nickel wire is used as the auxiliary electrode to detect glucose in 0.1M KOH solution, with a sensitivity as high as 40.2mA·mM -1 cm -2 .

Embodiment 2

[0041] First configure 10mM NH 4 NO 3 -10mM Cu(NO 3 ) 2 -10mM Co(NO 3 ) 2 Mix the solution, then wash with 1M HNO 3 Adjust the pH to 4.5 as the electrolyte for later use, and pass through argon for 30 minutes to remove dissolved oxygen. Two pieces of ruthenium-plated titanium are used as auxiliary anodes, and one piece of nickel foam is used as a working electrode (cathode), placed in parallel in the order of anode-cathode-anode, and the prepared electrolyte is added. Apply 10mA·cm -2 The electric current is deposited for 360s. After the end of the electrodeposition process, the electrodes were quickly taken out, washed with water, and then dried for later use. After the composite electrode material is welded and packaged with wires, it is used as the working electrode of the glucose sensor, and the nickel wire is used as the auxiliary electrode to detect glucose in 0.1M KOH solution, with a sensitivity as high as 38.4mA·mM -1 cm -2 .

Embodiment 3

[0043] First configure 25mM (NH 4 ) 2 SO 4 -5mM CuSO 4 -20mM CoSO 4 Mix the solution, then wash with 1M H 2 SO 4 Adjust the pH to 3.5 as the electrolyte for later use, and pass through argon for 30 minutes to remove dissolved oxygen. Two pieces of ruthenium-plated titanium are used as auxiliary anodes, and one piece of nickel foam is used as the working electrode (cathode), placed in parallel in the order of anode-cathode-anode, adding the prepared electrolyte, and applying 100mAcm -2 The current is deposited for 120s. After the end of the electrodeposition process, the electrodes were quickly taken out, washed with water, and then dried for later use. After the composite electrode material is welded and packaged with wires, it is used as the working electrode of the glucose sensor, and the nickel wire is used as the auxiliary electrode to detect glucose in 0.1M KOH solution, with a sensitivity as high as 42.6mA·mM -1 cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com