Tight sandstone core pore connectivity analysis method based on fluid injection

A tight sandstone and fluid injection technology, applied in the direction of material analysis, image analysis, material analysis using wave/particle radiation, etc., can solve skin and eye burns, tight sandstone nanoscale micropore marking, and affect tight sandstone reservoir pore connectivity Accurate evaluation of safety and other issues, to achieve the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the methods for analyzing the pore connectivity of tight sandstone cores based on fluid injection provided in Examples 1 and 2, sodium iodide and potassium iodide were respectively used as infiltration fluids for saturation treatment. Except for different infiltration fluids, other operating steps were the same.

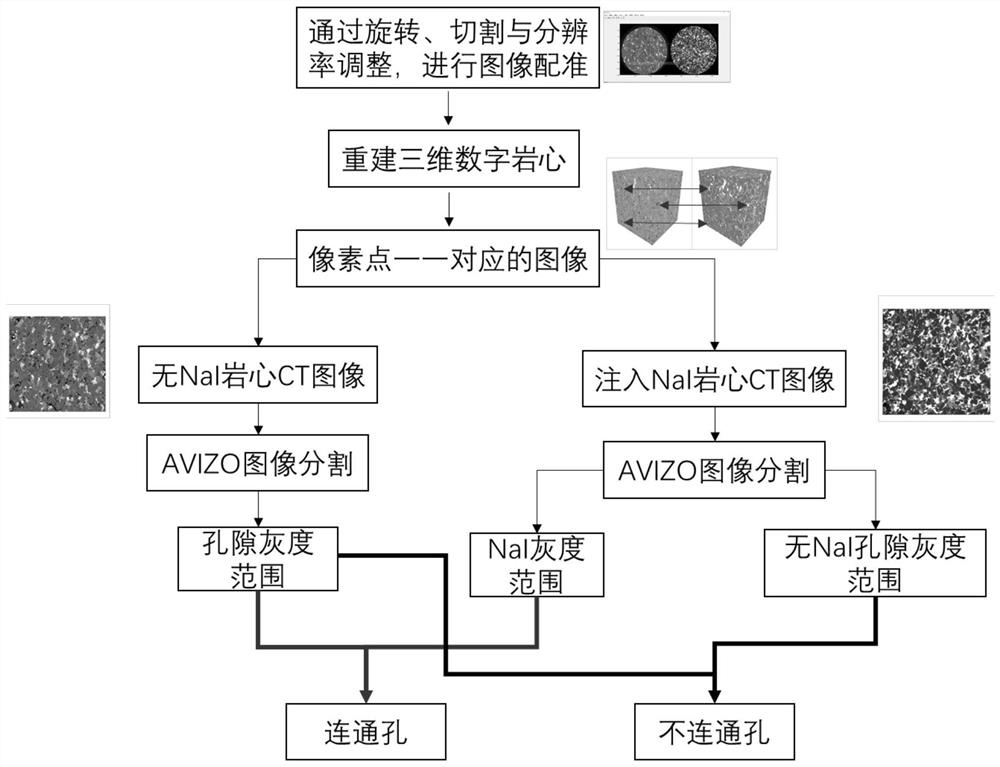

[0034] Wherein, the method for analyzing the pore connectivity of the tight sandstone core based on fluid injection provided in Example 1, the specific steps are as follows:

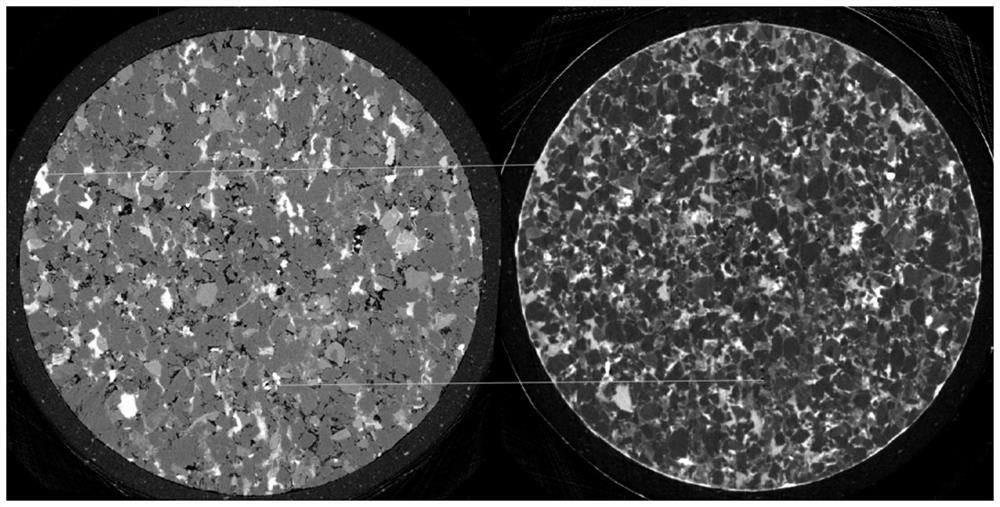

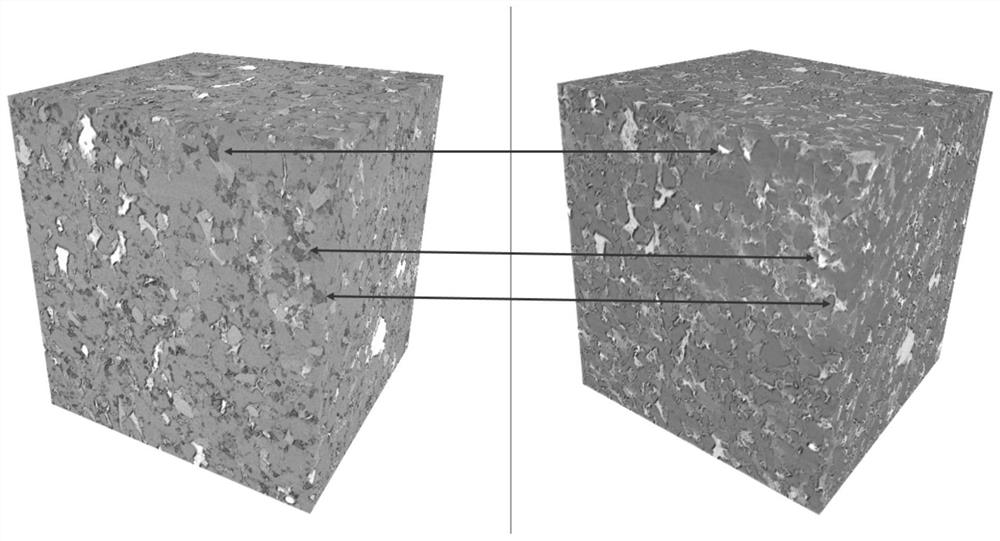

[0035] S1. Take a tight sandstone core, drill a cylindrical core sample with a diameter of 3 mm, and after polishing both ends, perform X-ray CT scanning on the core sample to obtain an X-CT three-dimensional grayscale image with a scanning resolution of 2.99 microns.

[0036] S2, carry out saturation treatment to rock core sample, make sodium iodide infiltrate in rock core pore, concrete steps are:

[0037] At room temperature, put the core into a saturated sodium iodide solution for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap