Purification method of bis(fluorosulfonyl)imide

A technology of bisfluorosulfonimide and purification method, which is applied in the directions of nitrosyl chloride, nitrogen and non-metallic compounds, etc., can solve the problems of loss of bisfluorosulfonimide products, difficult to remove, etc., to solve the problem of sublimation residue, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The purification method of bisfluorosulfonimide, the steps are as follows:

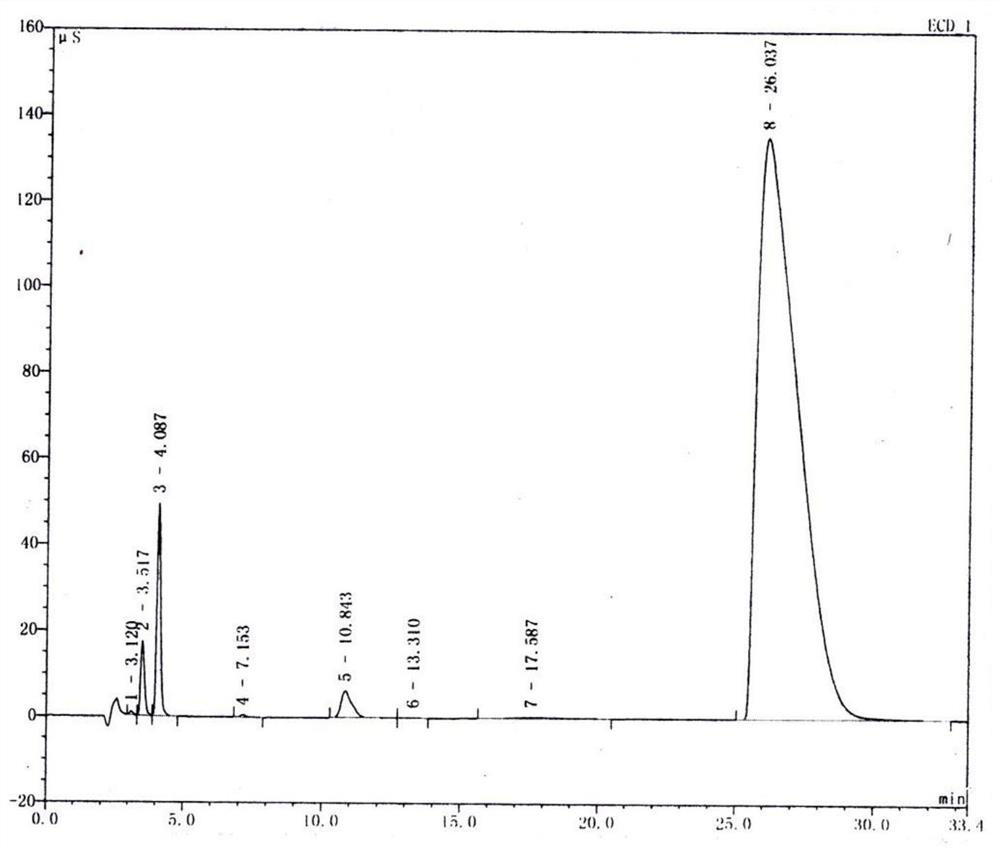

[0031] by SbF 3 The bisfluorosulfonimide crude product prepared by fluorination is 300g, and its chloride content is 1361ppm, and the ion chromatogram is shown in figure 1 ,Depend on figure 1 It can be seen that SbF 3 The HFSI crude product ion chromatogram obtained by fluorination has obvious chloride ion characteristic peak (retention time 4.087), and its chloride ion content is 1361ppm after conversion of the standard curve.

[0032] Under the protection of dry nitrogen, the above crude bisfluorosulfonimide (HFSI) was added into a 1L three-necked flask, and 1.68 g of sulfamic acid was added at the same time. Connect the reflux condenser and the bubbler, heat the device to 60°C with an oil bath, and stir the reaction, during which acid gas will be generated in the bubbler. After 10 hours of reaction, no gas was generated, and the heating was stopped, and the temperature of the contents in...

Embodiment 2

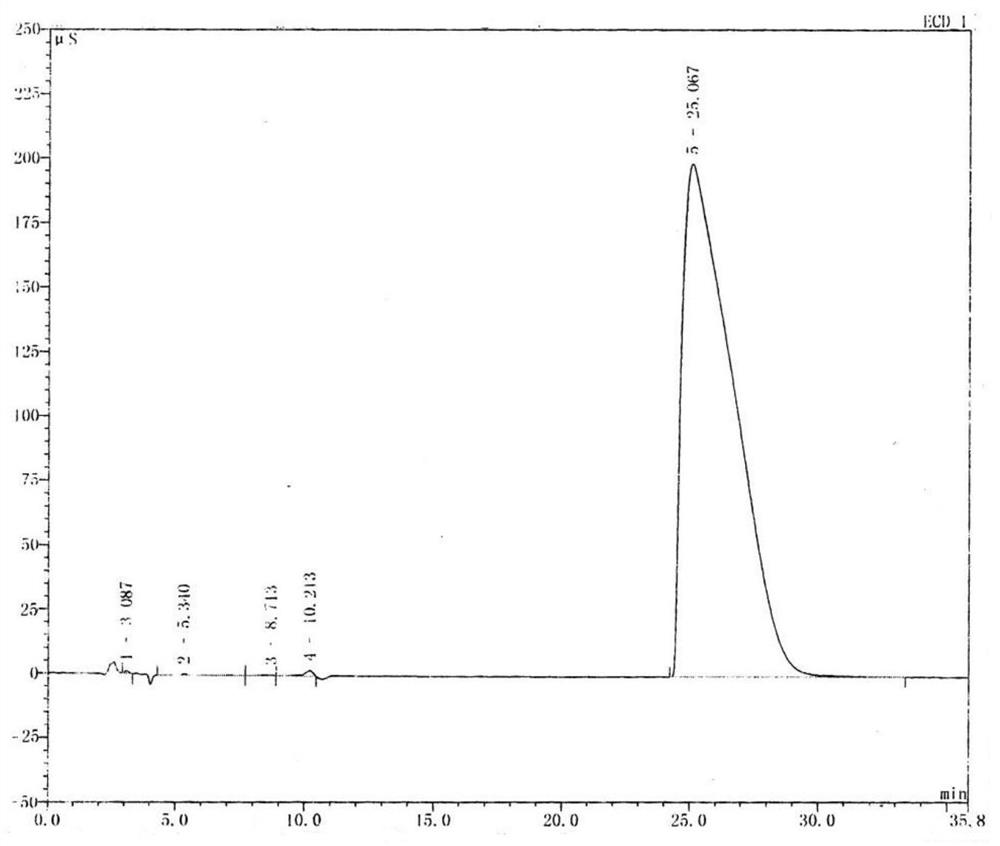

[0034] by SbF 3 The crude product of bisfluorosulfonimide prepared by fluorination was 300g, and its chloride content was 1361ppm. Under the protection of dry nitrogen, the above crude bisfluorosulfonimide (HFSI) was added into a 1L three-necked flask, and 3.45 g of tartaric acid was added at the same time. Connect the reflux condenser and the bubbler, heat the device to 80°C with an oil bath, and stir the reaction, during which acid gas will be generated in the bubbler. After 6 hours of reaction, no gas was generated, and the heating was stopped, and the temperature of the contents in the flask was lowered to below 30°C. Replace the reflux device with a vacuum distillation device, 100Pa, vacuum distillation / rectification at 40-80°C to obtain 281.4g of HFSI with a yield of 93.8%. A light brown solid remained in the flask. The refined HFSI is detected according to HJ / T 343-2007 "Determination of Chloride in Water Quality by Mercury Nitrate Titration (Trial)" method, wherein ...

Embodiment 3

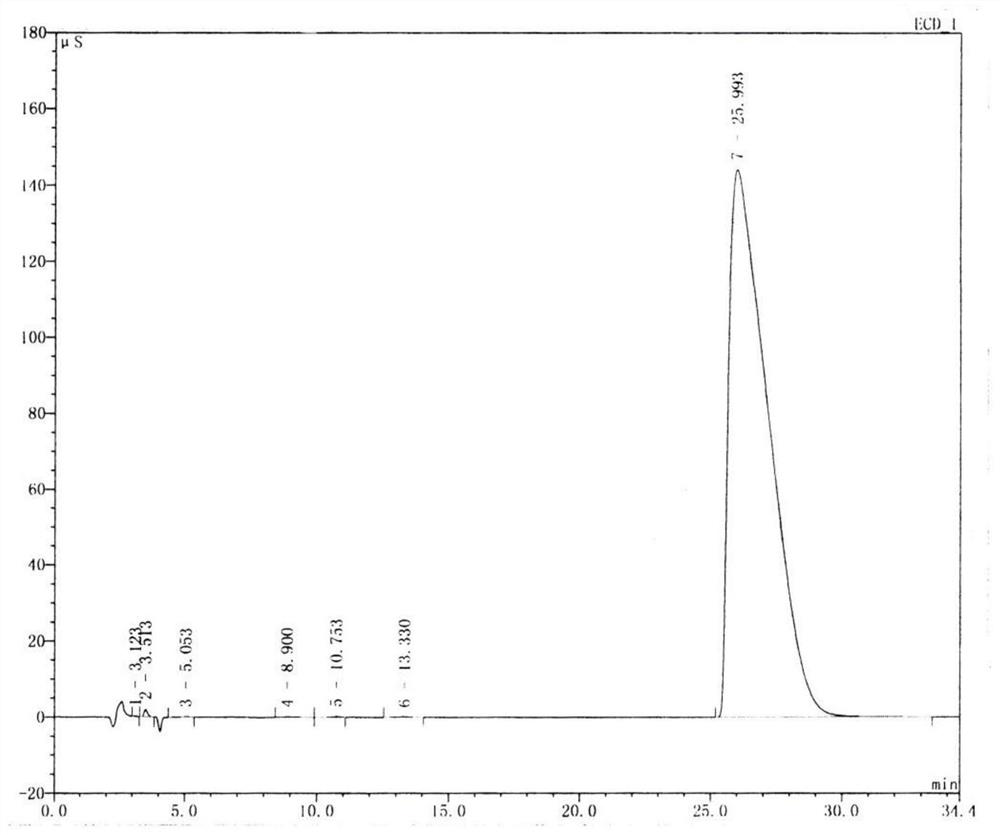

[0036] by BiF 3The crude product of bisfluorosulfonimide prepared by fluorination was 300g, and its chloride content was 738ppm. Under the protection of dry nitrogen, the above crude bisfluorosulfonimide (HFSI) was added into a 1L three-necked flask, and 4.78g of potassium citrate was added at the same time. Connect the reflux condenser and the bubbler, heat the device to 80°C with an oil bath, stir the reaction, no gas generation is observed in the bubbler. After 12 hours of reaction, the heating was stopped, and the temperature of the contents in the flask was lowered to below 30°C. The reflux device was replaced by a vacuum distillation device, 100 Pa, and vacuum distillation / rectification at 40-80 ° C to obtain HFSI291.2g, with a yield of 97.1%. An off-white solid remained in the flask. The refined HFSI is tested according to the method of HJ / T 343-2007 "Determination of Chloride in Water Quality by Mercury Nitrate Titration (Trial)", wherein the chloride content is 4pp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com