Oil sludge treatment system

A treatment system and oil sludge technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problem that sludge, oil and water are not completely separated, there are many particles in wastewater, equipment Problems such as large footprint, to achieve the effect of saving one-time investment, small footprint, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

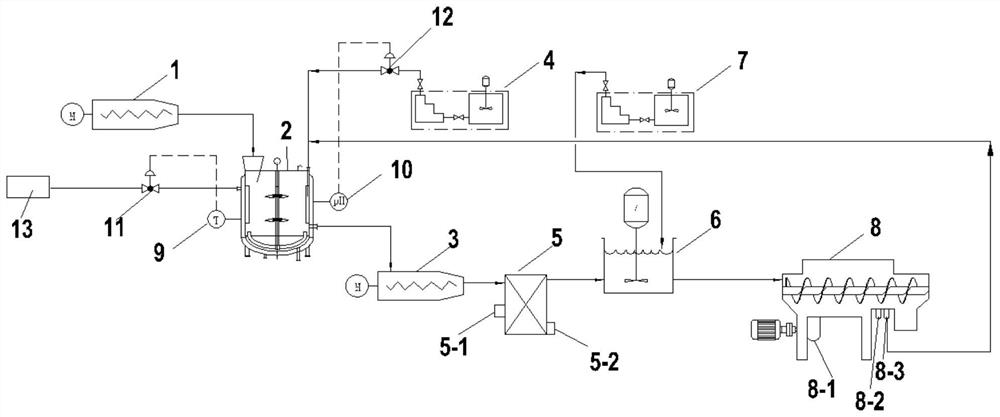

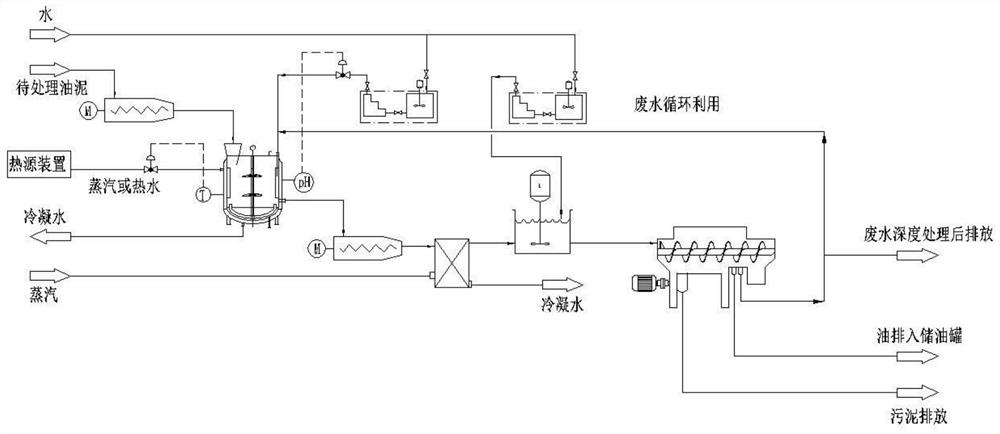

[0040] Such as figure 1 , an oil sludge treatment system, including a feeding device 1, an integrated oil sludge crushing and conditioning device 2, an oil sludge pump 3, a first dosing skid 4, a heat exchange device 5, a mixing tank 6, a second dosing skid 7 and three phase centrifugal separation device 8; the feeding device 1, the oil sludge crushing and conditioning integrated device 2, the sludge pump 3, the heat exchange device 5, the mixing tank 6 and the three-phase centrifugal separation device 8 are sequentially connected; the oil sludge crushing and conditioning A heat source inlet 2 - 1 is provided on the integrated device 2 ; the first chemical dosing skid 4 is connected to the integrated device 2 for oil sludge crushing and tempering, and the second chemical dosing skid 7 is connected to the mixing tank 6 .

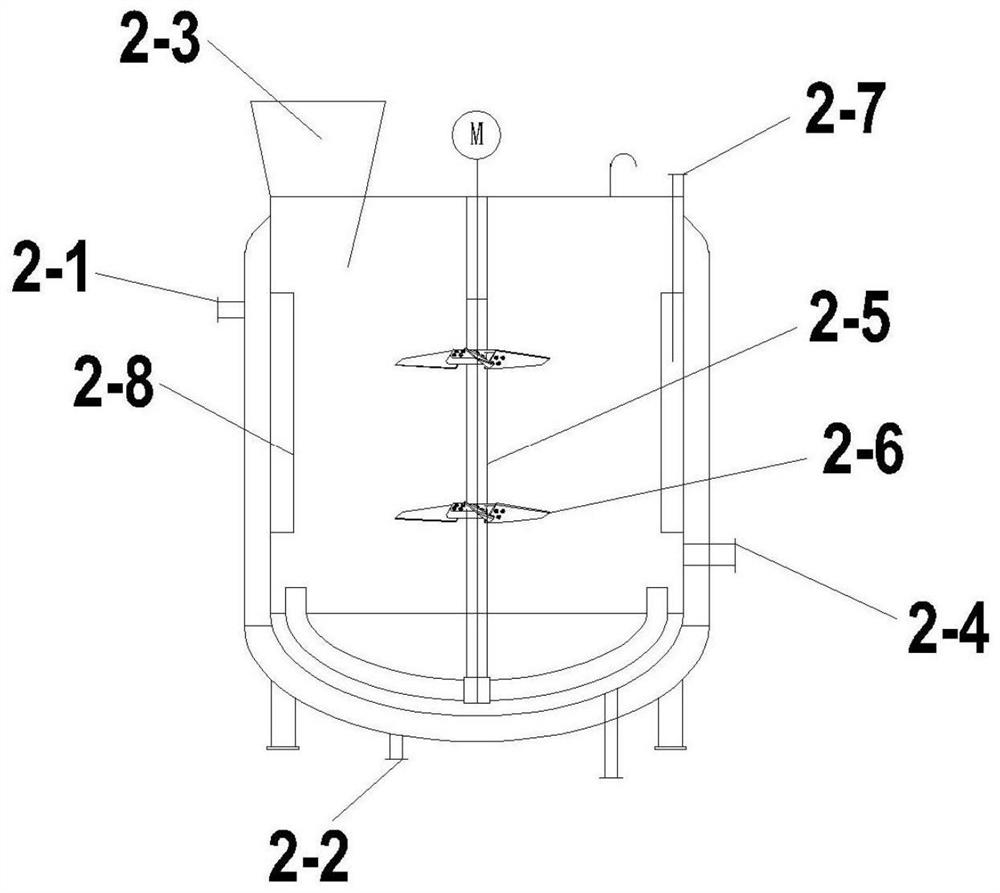

[0041] Such as figure 2 A temperature control device 9 is provided on the sludge crushing and conditioning integrated device 2, the heat source inlet 2-1 i...

Embodiment 2

[0044] Adopt the oil sludge treatment system of embodiment 1 to carry out oil sludge treatment, the source of the oil sludge adopted is tank bottom oil sludge, and the treatment process is:

[0045] Such as figure 1 , figure 2 and image 3 The oil sludge enters the oil sludge crushing and tempering integrated device 2 through the feeding device 1, and heat sources such as steam or hot water are passed from the heat source device 5 through the heat source inlet 2-1 into the oil sludge crushing and conditioning integrated device 2 to heat the oil sludge , and the heating temperature is controlled by the temperature control device 9 to be 90°C, and the dilution water is added to the sludge crushing and tempering integrated device 2 through the water inlet pipe 2-7 to dilute the sludge, and the sludge is crushed in the sludge crushing and conditioning integrated device 2 , demulsification, dilution and stirring. During the stirring process, the demulsifier potassium persulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com