Polishing process for improving surface roughness of silicon wafer

A silicon wafer surface and roughness technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problem of high silicon wafer roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

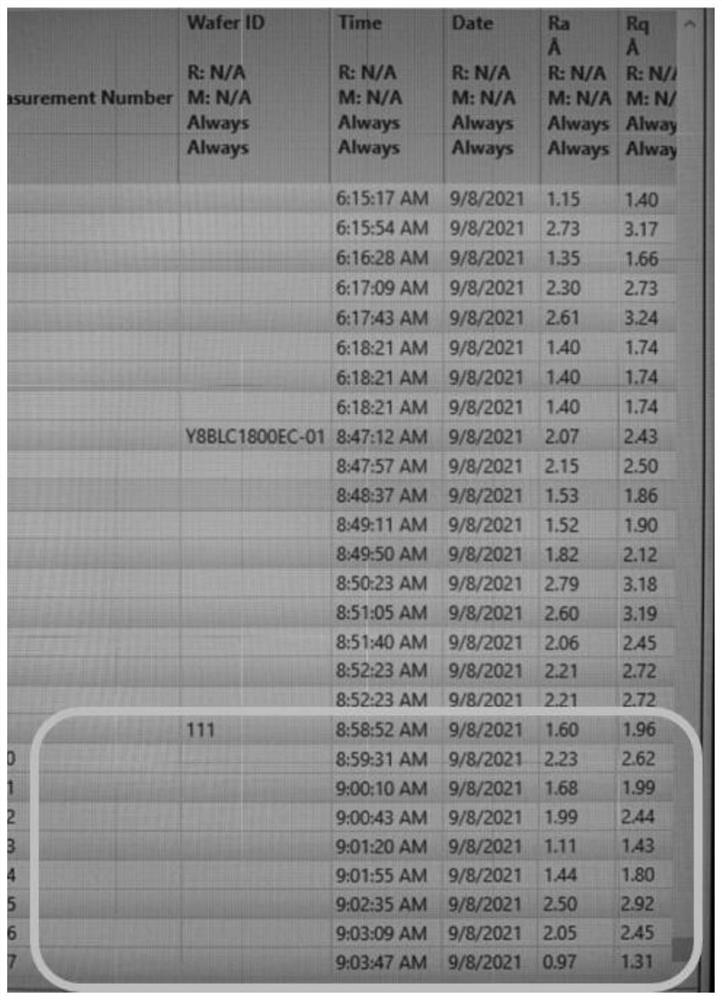

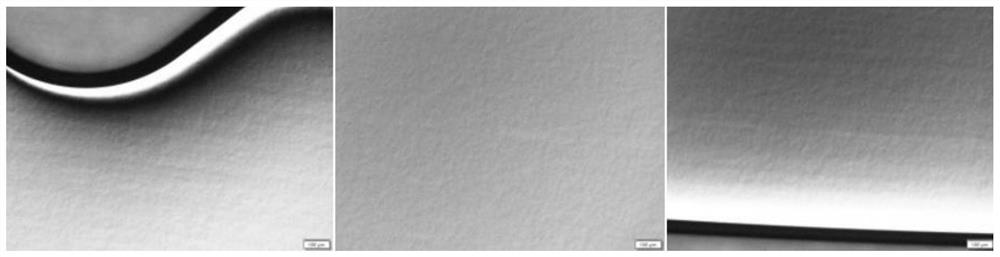

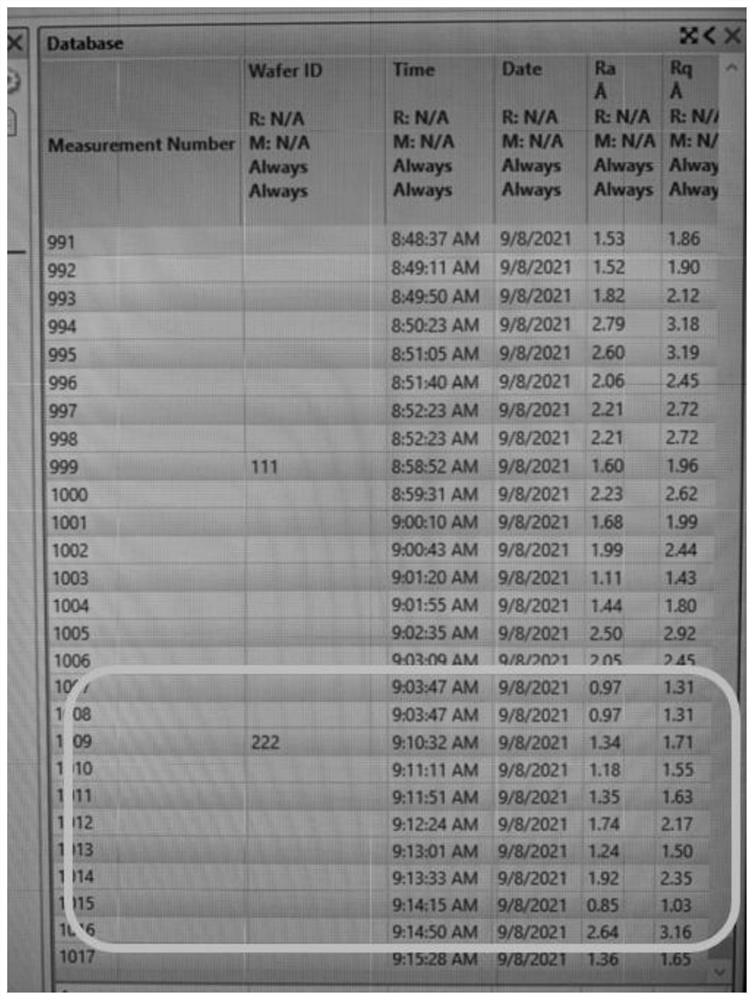

Image

Examples

Embodiment Construction

[0022] The specific implementation of the polishing process for improving the surface roughness of silicon wafers provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] A polishing process for improving the surface roughness of a silicon wafer, comprising the steps of:

[0024] S1. First, choose a crystal ingot with a diameter of 200mm and no single crystal defect (COP-Free), and check the equipment status before polishing to ensure that there is no abnormality before adjusting the process;

[0025] S2. Set the rotation speed of the large plate and the center guide wheel to 1:2, set the temperature of the ice polishing machine to 30°C, use NP6504 as the coarse polishing liquid, and the ratio is 1:15; use NP7000 as the medium polishing liquid, and the ratio is 1: 30; The fine polishing liquid is NP8000, and the ratio is 1:30. The concentration and temperature of the liquid will determine the strength of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com