Mold for manufacturing sand fixation plate connecting piece, preparation method and application

A technology for connectors and sand-fixing boards, which is applied in molds, manufacturing tools, supply devices, etc., can solve the problems of cumbersome manufacturing process and complex structure of sand-fixing board connectors, and achieve the effects of less staffing, cheap materials and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

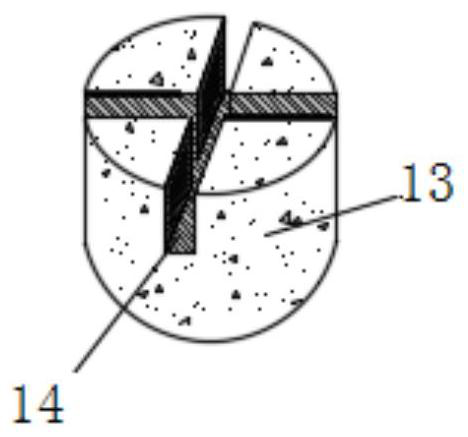

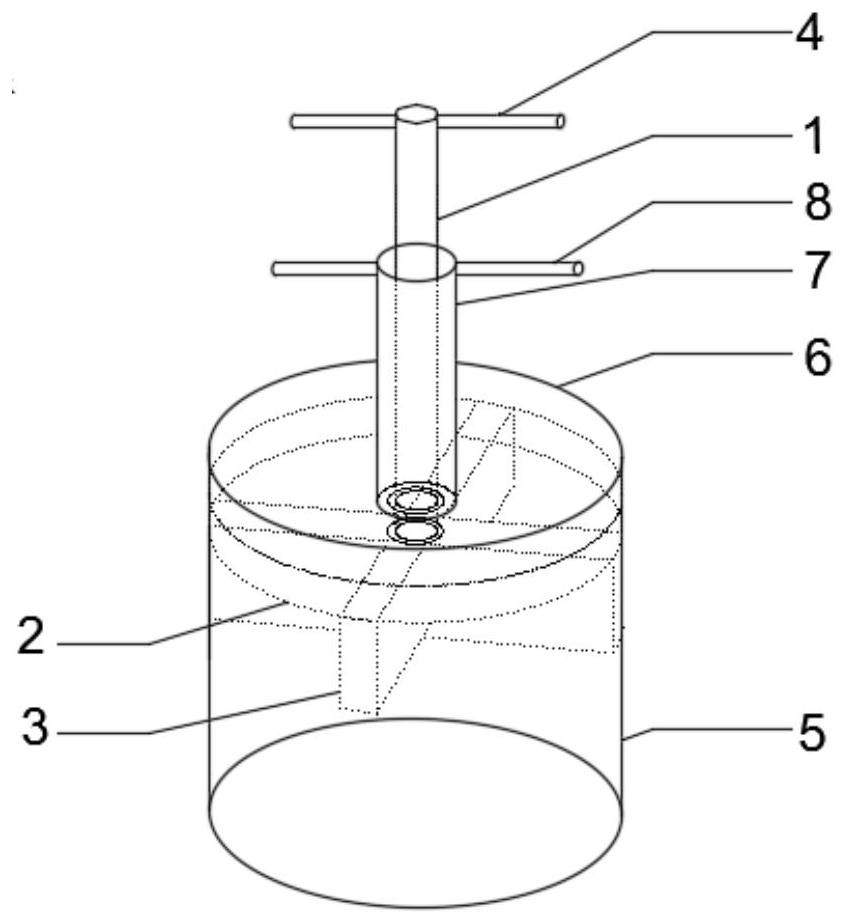

[0060] A mold for making a sand-fixing board connector, the structure of the sand-fixing board connector 13 is as follows figure 1 as shown in figure 2 As shown, the mold includes a piston member and a sleeve member, wherein:

[0061] The piston member includes a push rod 1, a first substrate 2 fixed on the bottom of the push rod 1, and a cross plate 3 fixed on the bottom surface of the first substrate 2, and the top of the push rod 1 is fixed with a first a handle 4;

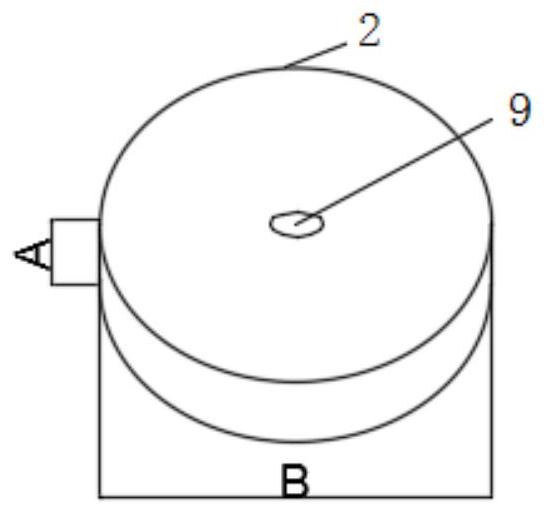

[0062] The sleeve member includes a cylinder body 5 with both ends open, a second substrate 6 sealing one end opening of the cylinder body 5, and a sleeve 7 fixed on the top surface of the second substrate 6, the The push rod 1 extends into the barrel 5 through the sleeve 7 and the hole 12 on the second substrate 6, and a second handle 8 is fixed on the top of the sleeve 7;

[0063] The first substrate 2 is driven by the push rod 1 to move up and down in the barrel 5, the outer periphery of the first substr...

Embodiment 2

[0073] Embodiment 2 prepares magnesium cement mortar 16

[0074] The water in the following embodiments is not limited, it can be tap water or river and lake water.

[0075] 2.1 Preparation of magnesium oxychloride cement mortar

[0076] Described magnesium oxychloride cement mortar is prepared by following method:

[0077] Step 1, dissolving magnesium chloride in water to obtain a magnesium salt solution with a concentration between 20-30Be °;

[0078] Step 2, active magnesia, sandy soil (sandy soil is sand and / or soil, obtained from sand control locality) and described magnesium salt solution by mass ratio 1:(5-15):(0.5-1.5) (optimum ratio 1:8:0.9, in addition, 1:5:1.5, 1:15:0.5, 1:5:0.5) can also be used to mix and stir evenly to obtain magnesium oxychloride cement mortar.

[0079] 2.2 Preparation of magnesium oxysulfide cement mortar

[0080] Described magnesium oxysulfide cement mortar is prepared by the following method:

[0081] Step 1, dissolving magnesium sulfate...

Embodiment 3

[0090] Utilize the method for the magnesium cement mortar of embodiment 2.1, 2.2 or 2.3 and the mold described in embodiment 1 to prepare connector, may further comprise the steps:

[0091] Press down the first handle 4 of the piston so that it is close to the second handle 8 (as Figure 8 ), and then pressed into the magnesium cement mortar, this moment due to the pressure the mortar is filled into the cylinder 5 of the mold (as Figure 9 ), finally mention the first handle 4 of the piston part and maintain the position of the second handle 8, the whole mold is taken out from the magnesium cement mortar, and the first handle 4 is pressed down to make the connector of the present invention (such as Figure 10 ). The connectors are cured in the air for 8-36 hours (the best curing time is 24 hours) and then hardened. The curing temperature is generally 0-30°C (the best curing temperature is 20°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com