Precise block polymer nanoassembly and preparation method thereof

A technology of block polymer and nano-assembly, which is applied in the field of precise block polymer nano-assembly and its preparation, can solve the problems of lack of mature technical rules and difficult realization, and achieves good uniformity and repeatability. The effect of single molecular weight and low dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] The present invention also provides a method for preparing the block polymer nano-assembly described in the above technical scheme, comprising the following steps:

[0097] a) dissolving the block polymer of formula I in an organic solvent to obtain a solution;

[0098] b) After mixing the dissolving solution with water, the organic solvent is removed by dialysis to form a nano-assembly.

[0099] In the present invention, for the preparation of nanospheres, there are specifically two preparation methods, and the first preparation method includes the following steps:

[0100] a1) dissolving the block polymer of formula I in an organic solvent to obtain a solution;

[0101] b1) After adding the dissolving solution into rapidly stirring water, the organic solvent is removed by dialysis to form nanospheres.

[0102] Regarding step a1):

[0103] The block polymer of formula I is preferably: n is an integer selected from 1 to 6, R=R 1 =H. The organic solvent is one or mo...

Embodiment 1

[0141] Example 1 Preparation of block polymer T-A of formula I 4 -dPEG spherical nanoparticles

[0142] 1.1 Preparation

[0143] The block polymer T-A 4 -dPEG was dissolved in dioxane (1 mg / mL) to obtain a solution. Under the stirring condition of 1000 rpm, 1 mL of the above dissolving solution was quickly poured into 9 mL of water at one time, and the stirring was continued for 2 h. Then, the solution was transferred to a dialysis membrane and dialyzed against water to remove the organic solvent, and dialyzed against pure water and changed the water several times to obtain an aqueous solution of the nano-assembly.

[0144] 1.2 Characterization and testing

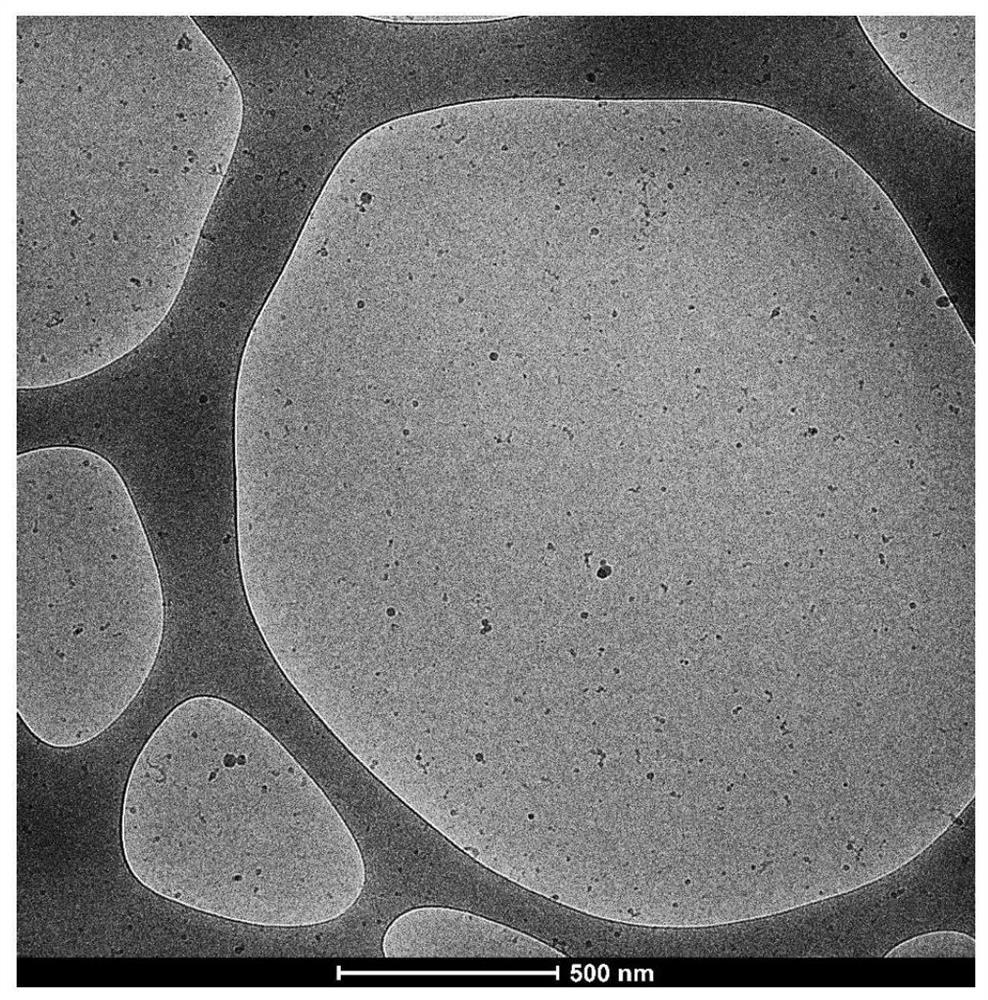

[0145] Cryo-electron microscope test chart is as follows figure 1 shown, figure 1 For the T-A gained in Example 1 4 - Cryo-TEM image of spherical nanoparticles of dPEG. It can be seen that the obtained assemblies are spherical nanoparticles with an average diameter of about 20 nm.

[0146] Performance testing of t...

Embodiment 2

[0150] Example 2 Preparation of block polymer T-A of formula I 6 -dPEG spherical nanoparticles

[0151] 1.1 Preparation

[0152] The block polymer T-A 6 -dPEG was dissolved in 1,4-dioxane (1 mg / mL) to obtain a solution. Under the stirring condition of 500 rpm, 9 mL of water was added to the above-mentioned dissolving solution containing 1 mL of solvent by using a syringe pump at a water addition rate of 1 mL / h, and the stirring was continued for 2 h. Then, the solution was transferred to a dialysis membrane and dialyzed against water to remove the organic solvent, and dialyzed against pure water and changed the water several times to obtain an aqueous solution of the nano-assembly.

[0153] 1.2 Characterization and testing

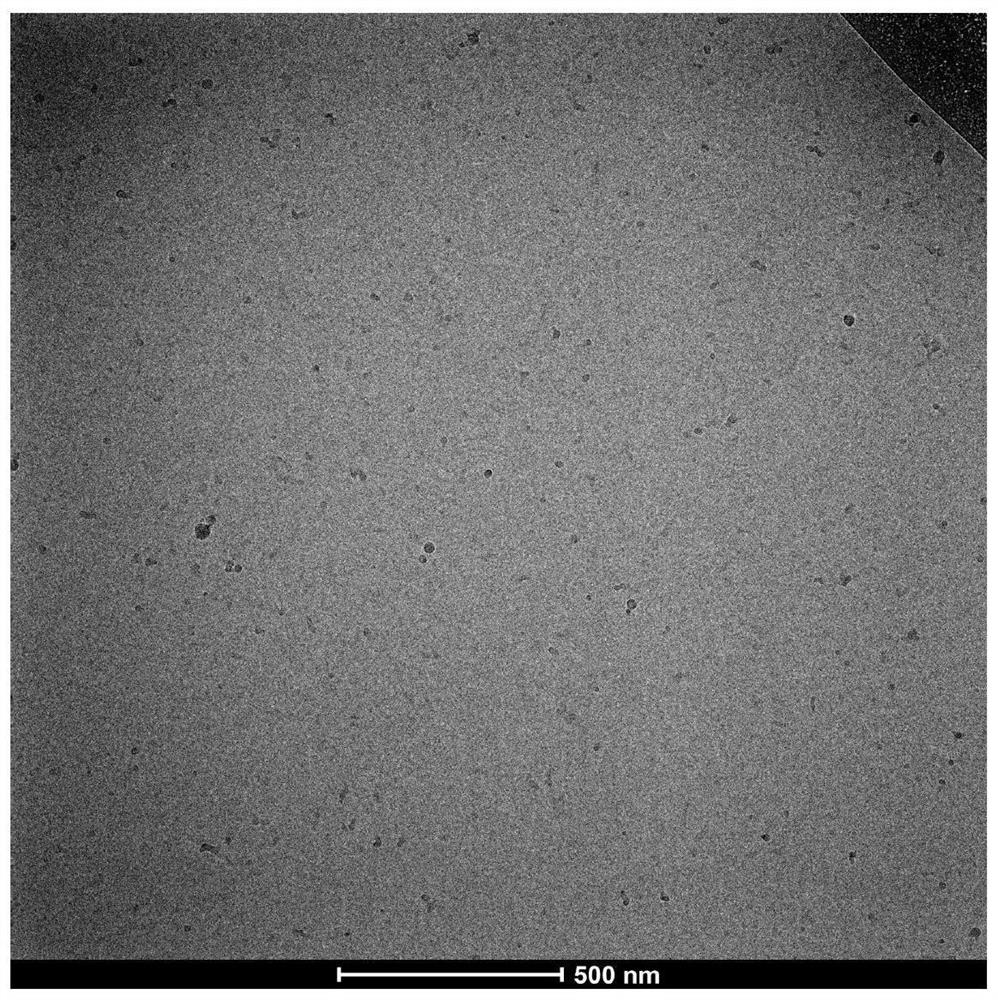

[0154] Cryo-electron microscope test chart is as follows figure 2 shown, figure 2 For the T-A gained in Example 2 6 - Cryo-TEM image of spherical nanoparticles of dPEG. It can be seen that the obtained assemblies are spherical nanoparticles with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com