Preparation method of 1-propene-1,3-sultone

A technology of sultone and propylene, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve problems such as restricting development, and achieve faster reaction speed and improved product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

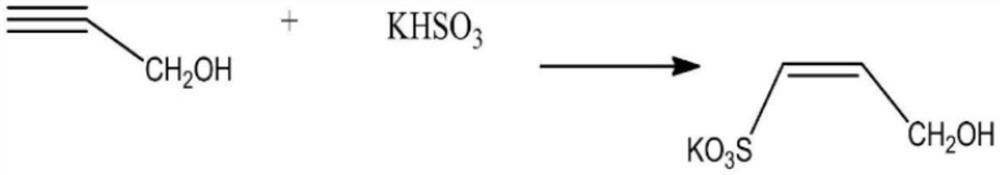

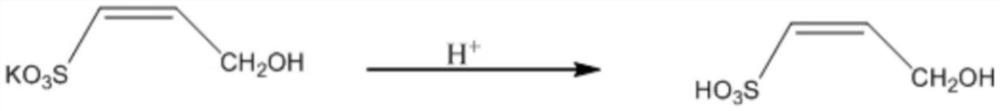

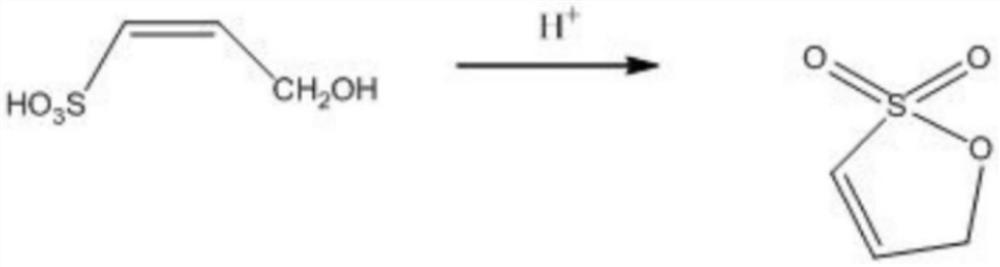

[0011] A preparation method of 1-propene-1,3-sultone, comprising carrying out addition reaction with propargyl alcohol and alkali metal sulfite or bisulfite under the action of a catalyst, adding Inorganic acid or organic acid is acidified, and the acidified product is separated, and then the cyclosynthesis reaction is carried out, and the 1-propene-1,3-sultone product is separated again. The key is: the catalyst in the addition reaction The components are composed by mass percentage: 60-80% of onium salt and 20-40% of crown ether.

[0012] The onium salt is trimethylbenzyl ammonium chloride, or tetrabutylammonium bisulfate, or a mixture of the above two substances.

[0013] The crown ether is 18-crown ether-6 with a solubility of 5-10%.

[0014] After the acidification process is finished, the pH value of the reaction solution is controlled to reach 3.5-3.8.

[0015] The molar ratio of propargyl alcohol to alkali metal sulfite or bisulfite is (1-10):1.

[0016] The reactio...

Embodiment 1

[0025] The catalyst air in the comparative example was replaced with 80ml of trimethylbenzyl ammonium chloride and 20ml of 18-crown-6. The test results showed that the reaction time was 35min, the yield was 98%, and the purity could reach chemical purity.

Embodiment 2

[0027] The catalyst air in the comparative example was replaced with 60ml of trimethylbenzyl ammonium chloride and 40ml of 18-crown-6. The test results showed that the reaction time was 36min, the yield was 97%, and the purity could reach chemical purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com