Polypropylene composition and preparation method thereof

A technology of polypropylene composition and polypropylene resin, which is applied in the field of polypropylene composition and its preparation, can solve the problems that cannot meet the requirements of the appearance of auto parts, etc., and achieve good appearance, suppress the formation of pitting, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

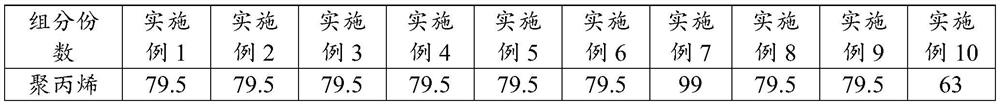

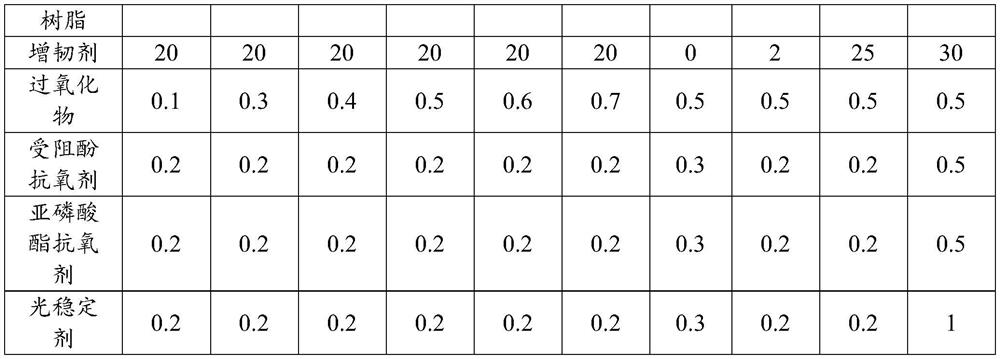

[0037] An embodiment of the polypropylene composition of the present invention and the preparation method thereof, as shown in Table 1.

[0038] The preparation method of the polypropylene composition includes the following steps:

[0039] The polypropylene resin, toughening, peroxide, and aid is mixed and uniformly added to the twin screw extruder, and the polypropylene composition is obtained by melt-kneading and extruding granulation; the melt mixing The temperature at the time of 170 ~ 220 ° C, the screw rotation speed in the twin screw extruder is 350 to 450 r / min.

[0040] The polypropylene resin is a copolymerized polypropylene resin, and the medium sea shell company produces PP EP648U products; the melt mass flow rate of the polypropylene resin is 60 g / 10 min;

[0041] The toughening agent is an ethylene-butene copolymer, Dow Chemical Company produces PoE ENGAGE 7447 products; the density of the tough agent is 0.865g / cm 3 The melt mass flow rate of the toughening age...

Embodiment 2~10、 Embodiment 13、 Embodiment 15

[0047] The polypropylene of the present invention and the preparation method thereof, the component component of the polypropylene composition is shown in Table 1. The preparation method of the product described in each of the examples is in the same embodiment.

[0048] Example 5 The polypropylene resin is a copolymerized polypropylene, a medium sea shell company produces a PP EP548R product; the melt mass flow rate of the polypropylene resin is 30 g / 10 min; the tough agent is an ethylene-butene copolymer. , Dow Chemical Company produces PoE Engage 7447 products; the toughening agent has a density of 0.865g / cm 3 The melt mass flow rate of the toughening agent is 5 g / 10 min;

[0049] Example 6 The polypropylene resin is a homogeneous polypropylene, Lanzhou Petrochemical production PP H9018 product; the melt mass flow rate of the polypropylene resin is 60 g / 10 min; the tough agent is an ethylene-octene copolymer. , Dow Chemical Company produces PoE ENGAGE 8842, the density ...

Embodiment 12

[0052] The difference from the present embodiment and the fourth embodiment is only: the tough agent of the present embodiment is a polypropylene elastomer, and Exxon Mobil produces VistaMAX 3000 products, the density of the toughness is 0.873 g / cm. 3 The melt mass flow rate of the toughening agent is 8.0 g / 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com