Low-temperature bonded woven elastic shirt lining and preparation method thereof

A shirt and elastic technology, applied in the field of low-temperature bonded woven elastic shirt lining and its preparation, can solve the problems of reducing the comfort experience of the human body and lack of elasticity, and achieve the effect of avoiding the discoloration reaction of the fabric, increasing comfort, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

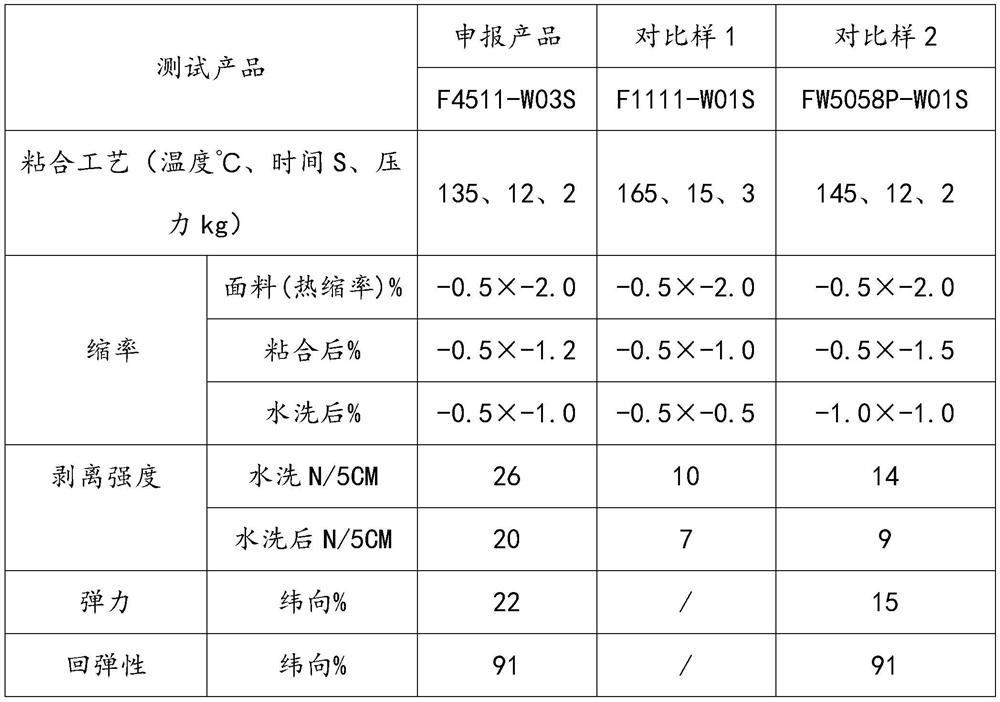

Examples

Embodiment 1

[0024] A low-temperature bonded woven elastic shirt lining, including radial yarns and weft yarns, the radial yarns are 9-80 British-count single yarn or ply of cotton, polyester, polyester-cotton blended or cotton-polyester blended. Yarn, the blending ratio is cotton 10-90%, polyester 10-90%;

[0025] The weft yarn is 30-300 denier high elastic yarn, the base fabric of the shirt lining is 1 / 1 plain weave, the density of the radial yarn is 50-120 yarns / inch, and the weft density of the weft yarn is 40-100 yarns / inch.

[0026] A method for preparing a low-temperature bonded woven elastic shirt lining, comprising the following production processes: a. sizing; b. weaving; c. dye vat desizing; d. stretching; e. resin finishing; f. loose coating layer.

[0027] In the d process: use high temperature 180-200 ℃ to control the heat shrinkage rate, because the weft direction is high elastic yarn, the main width of the setting machine is 120-121 cm, the width of the falling cloth is 11...

Embodiment 2

[0029] A low-temperature bonded woven elastic shirt lining, including radial yarns and weft yarns, the radial yarns are 9-80 British-count single yarn or ply of cotton, polyester, polyester-cotton blended or cotton-polyester blended. Yarn, the blending ratio is cotton 10-90%, polyester 10-90%;

[0030] The weft yarn is made of 30-300 denier high elastic yarn, the base fabric of the shirt lining is 1 / 1 plain weave, the warp density is 50-120 threads / inch, and the weft density is 40-100 threads / inch.

[0031] A method for preparing a low-temperature bonded woven elastic shirt lining, comprising the following production processes: a. sizing; b. weaving; c. dye vat desizing; d. stretching; e. resin finishing; f. loose coating layer.

[0032] Step e: add 20g / l silicone oil softener, temperature 170-175°C, vehicle speed 50 m / min, control the weft elasticity of falling cloth at 25-30%, silicone oil softener can endow the fabric with unique softness and smoothness , At the same time...

Embodiment 3

[0034] A low-temperature bonded woven elastic shirt lining, including radial yarns and weft yarns, the radial yarns are 9-80 British-count single yarn or ply of cotton, polyester, polyester-cotton blended or cotton-polyester blended. Yarn, the blending ratio is cotton 10-90%, polyester 10-90%;

[0035] The weft yarn is made of 30-300 denier high elastic yarn, the base fabric of the shirt lining is 1 / 1 plain weave, the warp density is 50-120 threads / inch, and the weft density is 40-100 threads / inch.

[0036] A method for preparing a low-temperature bonded woven elastic shirt lining, comprising the following production processes: a. sizing; b. weaving; c. dye vat desizing; d. stretching; e. resin finishing; f. loose coating layer.

[0037] In the f process: use imported low-temperature hot-melt adhesive PA powder, use flower rollers of 28-40 mesh, glue amount 10-35g / m2, vehicle speed 20 m / min, water temperature 50°C, oil temperature 220°C, drying room temperature 148°C , the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com