Molten salt reactor core and molten salt reactor system

A technology for molten salt reactors and cores, applied in reactors, reactor fuel materials, nuclear power generation, etc., can solve problems such as high construction costs, high thresholds, and low heat exchange efficiency, and improve operational safety, simplify structures, and improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

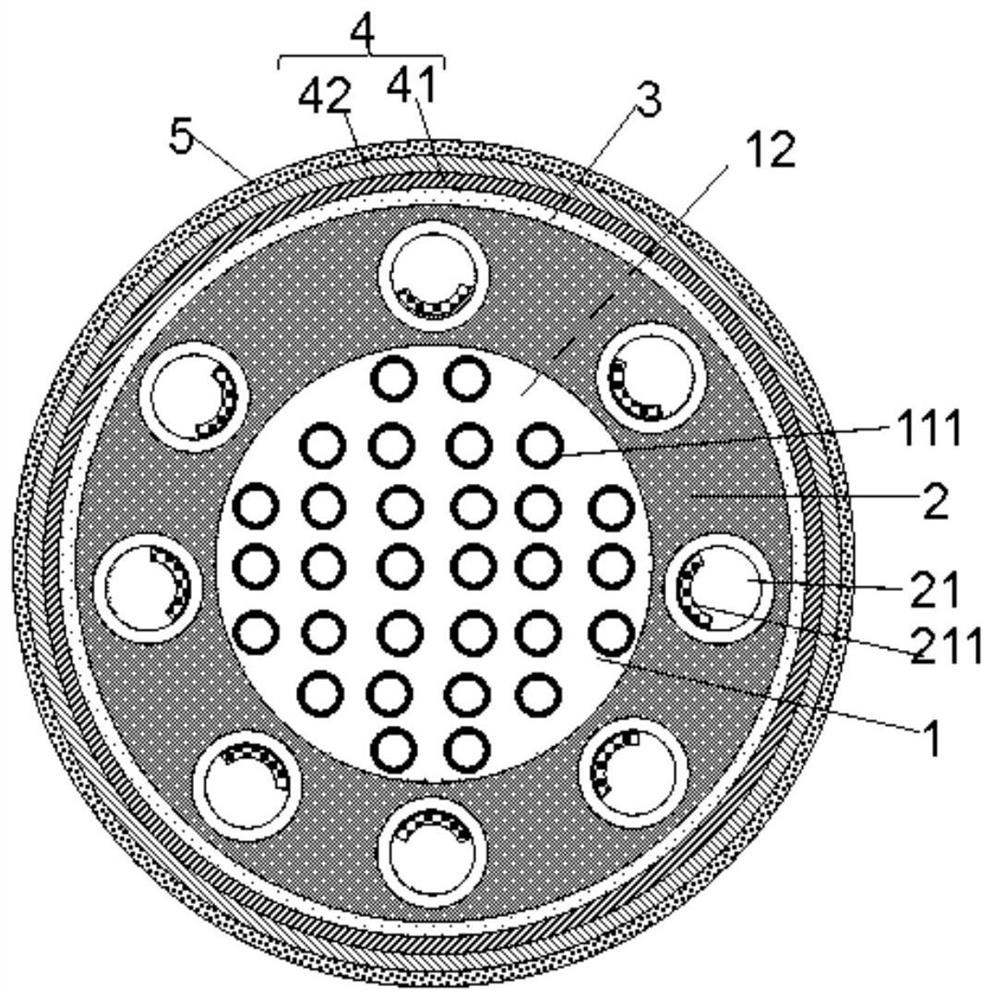

[0080] Such as figure 1 As shown, the coolant pipeline area 11 of the molten salt reactor core includes a coolant pipeline 111, a collection pipeline 112 and a distribution pipeline 113. The top end of the coolant pipeline 111 communicates with the collection pipeline 112, and the bottom end of the coolant pipeline 111 communicates with the distribution pipeline. 113 is connected; the collection pipe 112 is connected with the coolant outlet 6, and the distribution pipe 113 is connected with the coolant inlet 7; the coolant is circulated in the coolant pipe 111, and the coolant is a mixture of helium and xenon, and the molar ratio of xenon is 9.1% , the number of coolant pipes 111 is 121, the inner diameter of the coolant pipe 111 is 3.2cm, the material of the coolant pipe 111 is SiC, the wall thickness is 1mm, and the average flow velocity of the coolant in the coolant pipe 111 is 30m / s or so.

[0081] The molten salt reactor core includes core active area 1 , reflection lay...

Embodiment 2

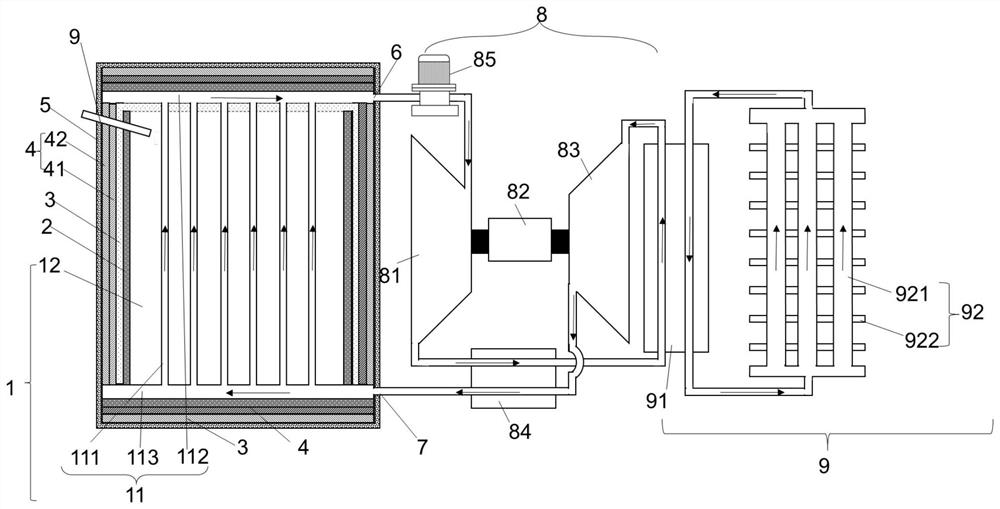

[0089] Such as image 3 As shown, the molten salt reactor system includes the molten salt reactor core of Embodiment 1, a thermoelectric conversion system 8 and a waste heat removal system 9 . The coolant outlet 6 of the molten salt reactor core is connected to the inlet of the thermoelectric conversion system 8 , and the coolant inlet 7 is connected to the outlet of the thermoelectric conversion system 8 .

[0090]The thermoelectric conversion system 8 includes a turbine 81, a generator 82, a compressor 83, a regenerator 84, and a coolant pump 85. The inlet of the turbine 81 is connected to the coolant outlet 6, and the turbine 81 is connected to the generator 82. The coolant The coolant flowing out of the outlet 6 has a temperature of 700°C and a gas pressure of 2 MPa. It expands adiabatically through the turbine 81 to perform work to the outside, and drives the generator 82 to generate electricity; the outlet of the turbine 81 is connected to the inlet of the compressor 83,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com