Heat treatment process of high-chromium heat-resistant alloy

A heat-resistant alloy and process technology, which is applied in the heat treatment process field of high-chromium heat-resistant alloys, can solve the problems of reduced martensite stability, coarse grain boundary precipitated phase size, and reduced durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: The deformed heat-resistant alloy includes the following components by weight percentage, C: 0.08%, Cr: 13%, Ni: 1%, Mn: 10%, Si: 0.4%, B: 0.005%, Mo: 1 %, W: 5%, Cu: 1%, and the balance is Fe.

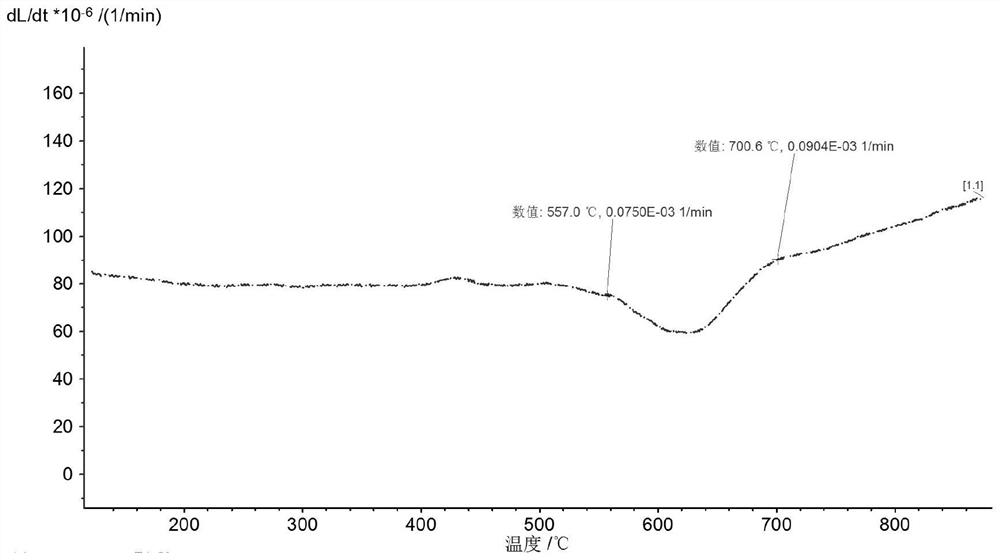

[0035] The melting temperature of the second phase at the grain boundary of the alloy was measured at 1102°C, and the complete austenitization temperature A was measured by thermal expansion method c3 is 700.6°C, such as figure 1 shown.

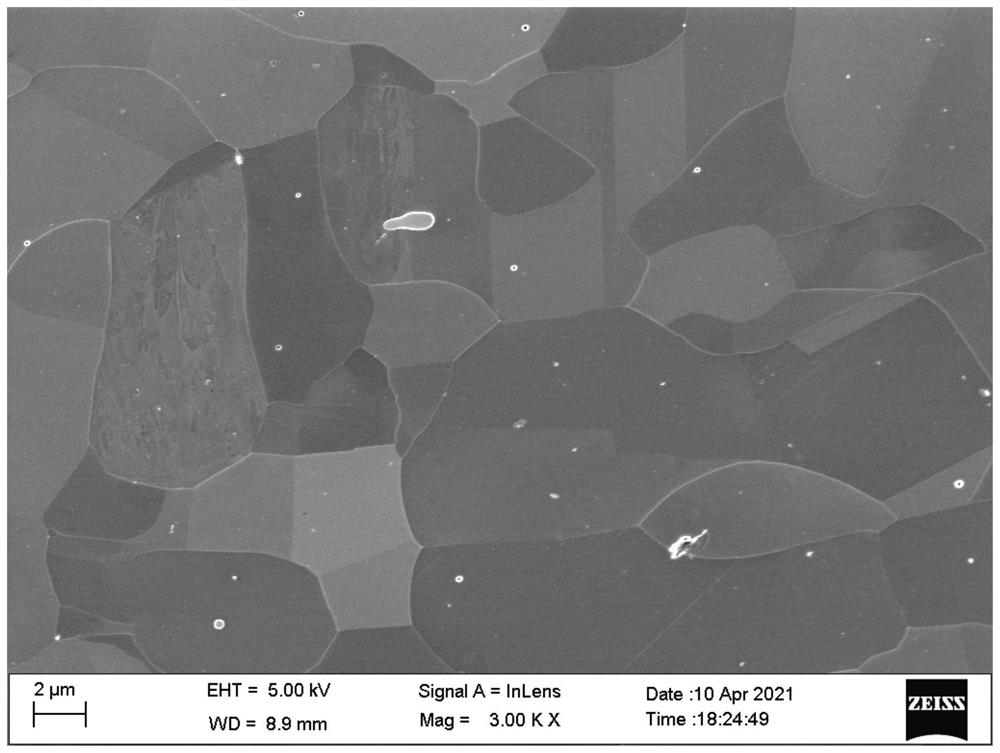

[0036] Heat the deformed heat-resistant alloy to 1120°C at a heating rate of 15°C / min, and keep it warm for 30 minutes to ensure that all precipitated phases are dissolved into the matrix for solid solution treatment, and then water-cooled to room temperature after completion. After solid solution treatment, the tissue such as figure 2 As shown, the volume fraction of austenite is 75-90%, and austenite contains a large number of twins;

[0037] Step 2: Heat the heat-resistant alloy after solution treatment to 680°C at a heating ra...

Embodiment 2

[0047] Step 1: The deformed heat-resistant alloy includes the following components by weight percentage, C: 0.08%, Cr: 15%, Ni: 1%, Mn: 10%, Si: 0.4%, B: 0.005%, Mo: 1 %, W: 5%, Cu: 1%, and the balance is Fe.

[0048] The melting temperature of the second phase at the grain boundary of the alloy was measured at 1108°C, and the complete austenitization temperature A was measured by thermal expansion method c3 It is 706°C. refer to figure 1 , heat the deformed heat-resistant alloy to 1110°C at a heating rate of 10°C / min, and keep it warm for 30 minutes to ensure that all precipitated phases dissolve into the matrix, and carry out solid solution treatment. After completion, water cool to room temperature;

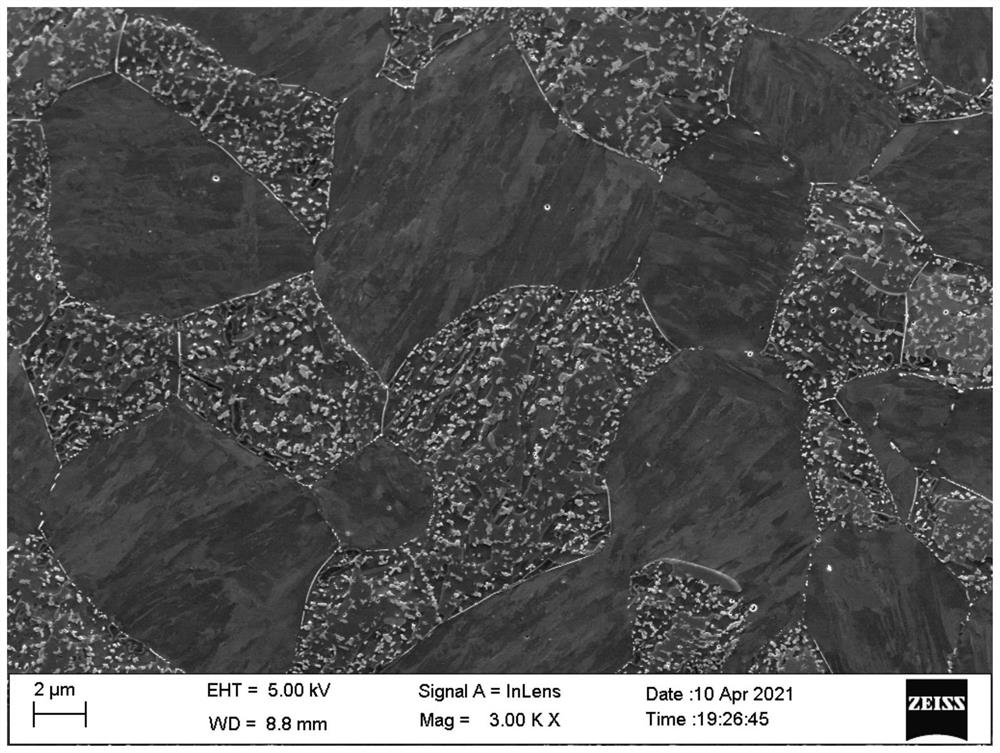

[0049] Step 2: Heat the heat-resistant alloy after solution treatment to 675°C at a heating rate of 10°C / min, keep it warm for 12 hours, complete the aging treatment, and then cool it to room temperature. The obtained tissue is as follows: Figure 6 shown. The matrix struc...

Embodiment 3

[0051] Step 1: The deformed heat-resistant alloy includes the following components by weight percentage, C: 0.05%, Cr: 11.5%, Ni: 1.6%, Mn: 10%, Si: 0.3%, B: 0.007%, Mo: 1.5 %, W: 4%, Cu: 1.2%, Al: 1%, and the balance is Fe.

[0052] After measuring the dissolution temperature of the second phase of the alloy grain boundary at 1106°C, the complete austenitization temperature A of the heat-resistant alloy was measured by the thermal expansion method c3 It is 705°C. refer to figure 1 , heating the deformed heat-resistant alloy to 1120°C at a heating rate of 10°C / min, and holding it for 30 minutes to ensure that all precipitated phases are dissolved into the matrix, and carry out solid solution treatment. After completion, water cool to room temperature;

[0053] Step 2: Heat the heat-resistant alloy after solution treatment to 665° C. at a heating rate of 10° C. / min, keep it warm for 12 hours, complete the aging treatment, and then water-cool to room temperature. The obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com