Muck improvement method

A technology for improving dregs and dregs, which is applied in the fields of earth square drilling, cleaning methods and tools, chemical instruments and methods, etc., can solve the problems of low efficiency of dregs improvement, achieve improvement of low-efficiency defects, reduce bulk density, and are not easy to produce mud cake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

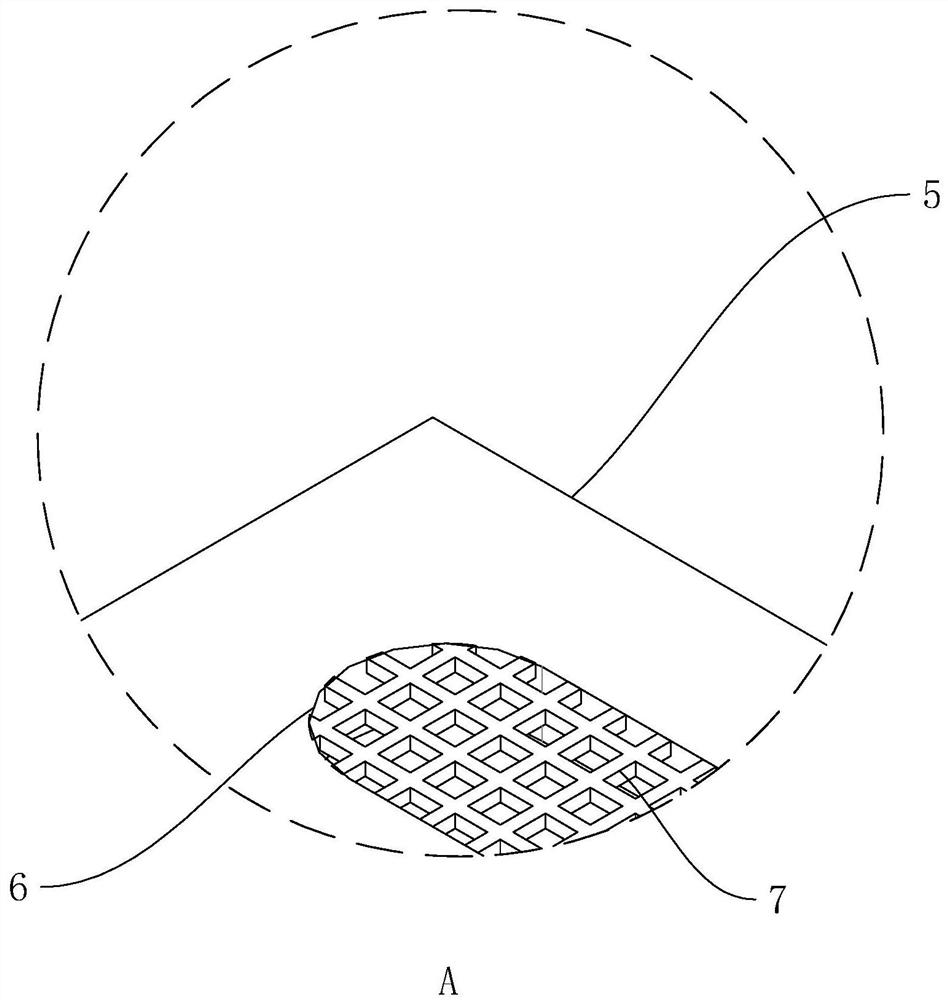

[0037] The following is attached Figure 1-4 The application is described in further detail.

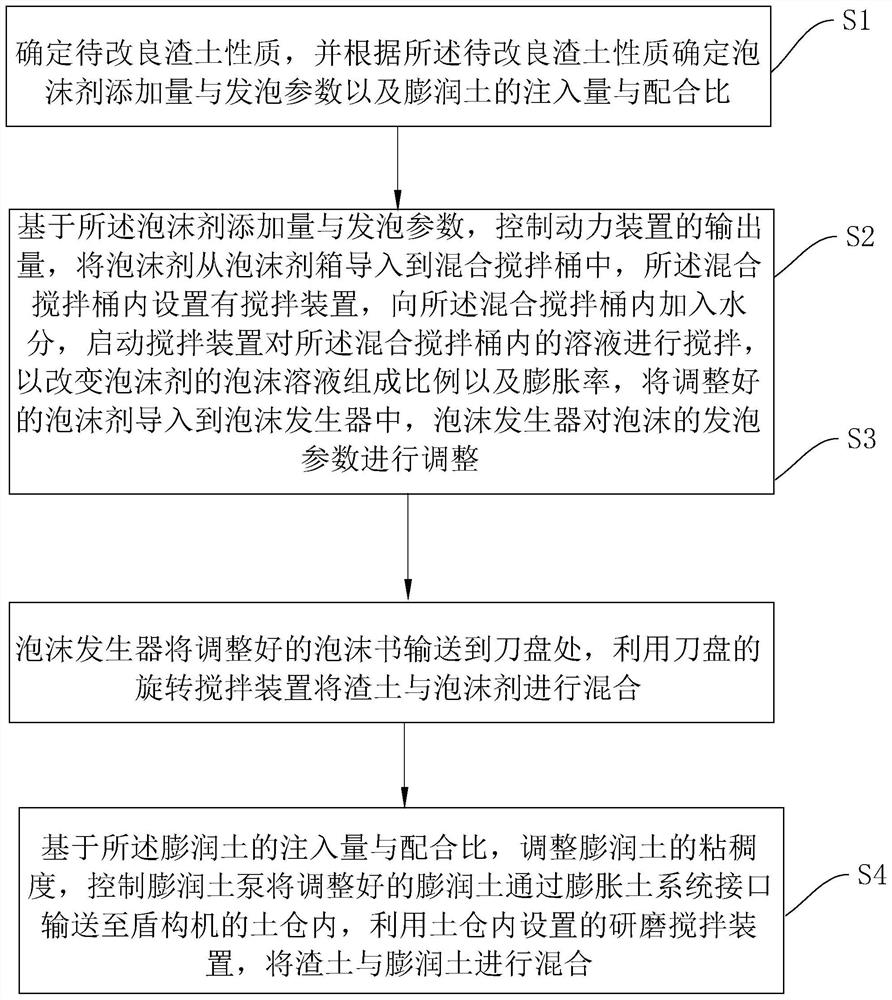

[0038] The embodiment of the present application discloses a method for improving dregs, referring to figure 1 , including the following steps:

[0039] S1. Collect slag samples, test the slag samples, collect the test data of the slag, and determine the properties of the slag according to the test data, and determine the amount of foaming agent, foaming parameters and injection of bentonite according to the properties of the slag to be improved Quantity and mix ratio;

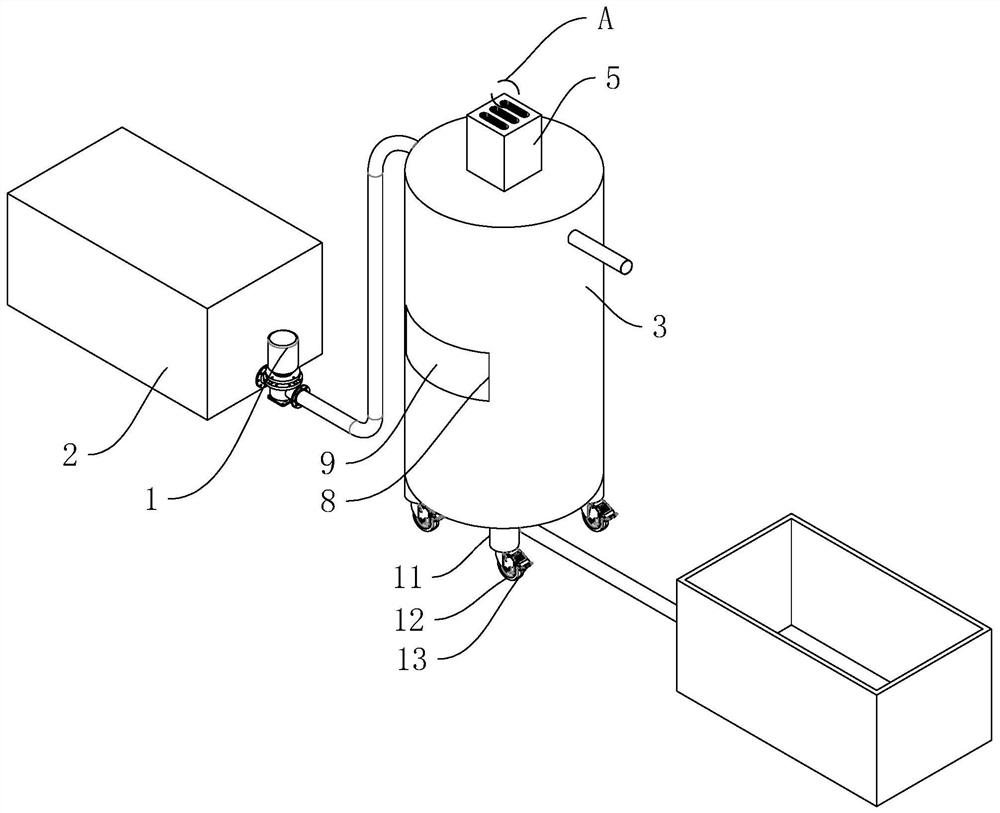

[0040] S2. Based on the amount of foam agent added and the foaming parameters, the output of foam agent pump 1 is controlled. The feed end of foam agent pump 1 is connected to foam agent tank 2, and the discharge end of foam agent pump 1 is connected to mixing tank 3. , the foam agent is imported from the foam agent tank 2 into the mixing tank 3, the mixing tank 3 is provided with a stirring device 4, water is added...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap