Bioactive ceramic anti-browning apple juice enzyme deactivation device

A technology of bioactive ceramics and apple juice, which is applied in the food field, can solve the problems of poor heat preservation effect of heat medium, energy waste, high energy consumption, etc., and achieve the effect of favorable conditions for enzyme inactivation, stability, and large heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

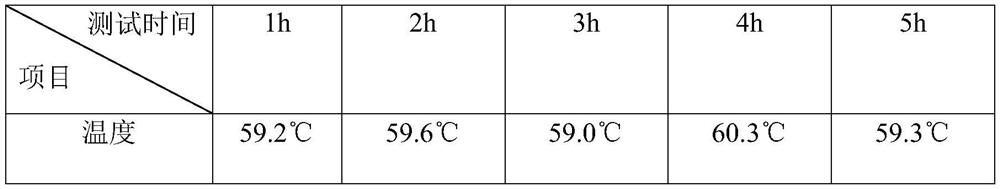

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0055] The raw materials used in the present invention, if no special instructions, are conventional commercially available products, the methods used in the present invention, if no special instructions, are conventional methods in this area, and the quality of each material used in the present invention is routine use quality. Structures, connections, etc. that are not described in detail in the present invention can be understood as conventional technical means in the art.

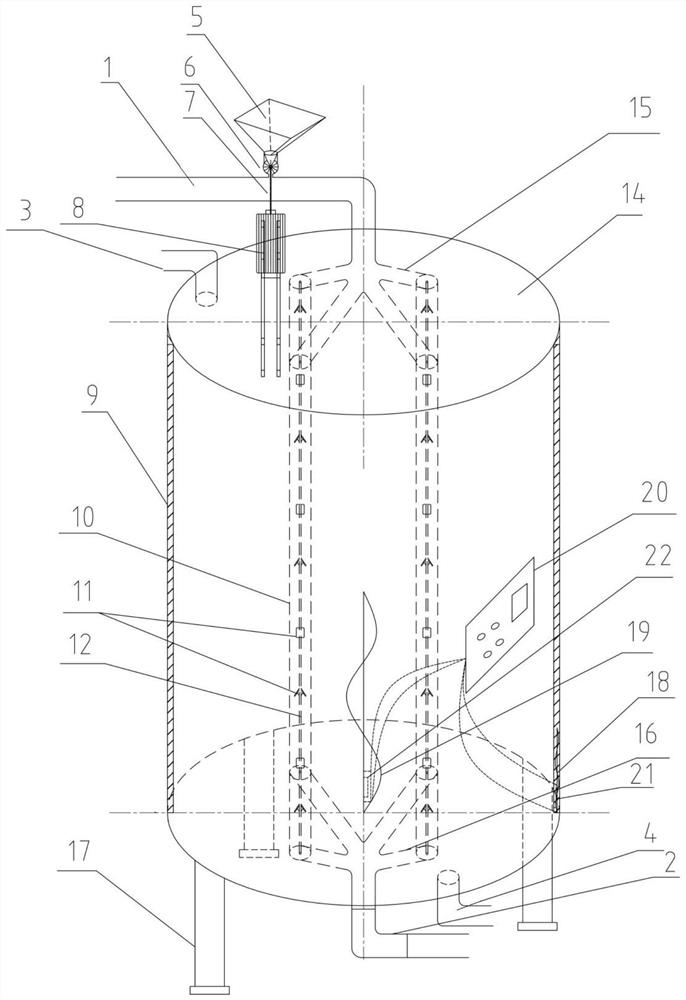

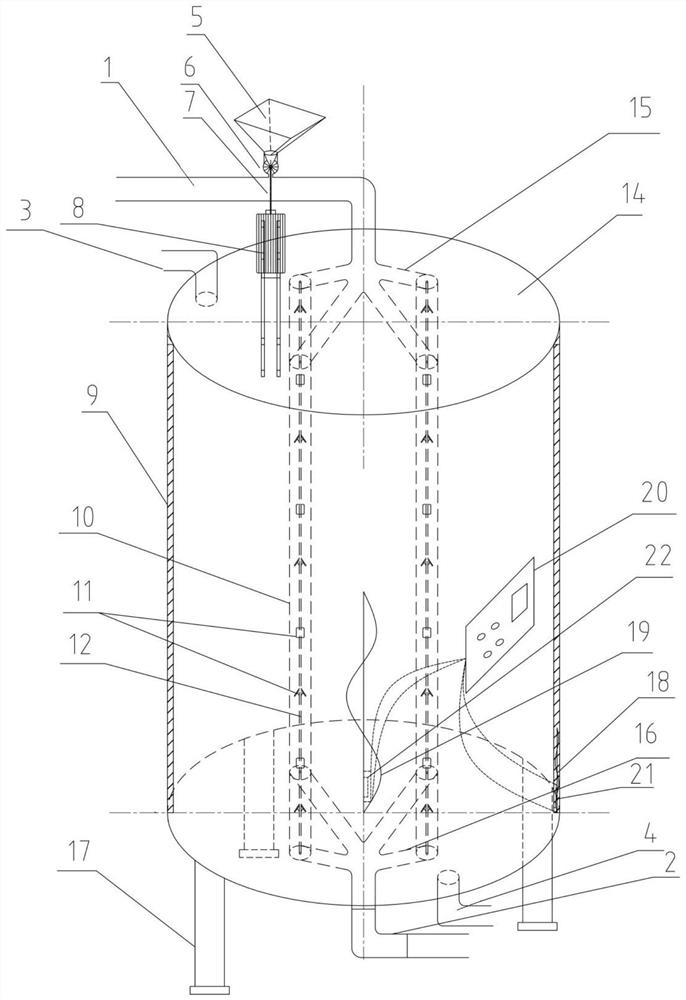

[0056] A bioactive ceramic anti-browning apple juice deactivation device, such as figure 1 As shown, the device includes an apple juice inlet pipe 1, an apple juice outlet pipe 2, a heat transfer medium outlet 3, a heat transfer medium inlet 4, a vitamin C addition hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com