Anti-agglomeration thickening type silicon dioxide and preparation method thereof

A technology for thickening silicon dioxide and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, cosmetic preparations, etc. Dispersion performance, excellent performance, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

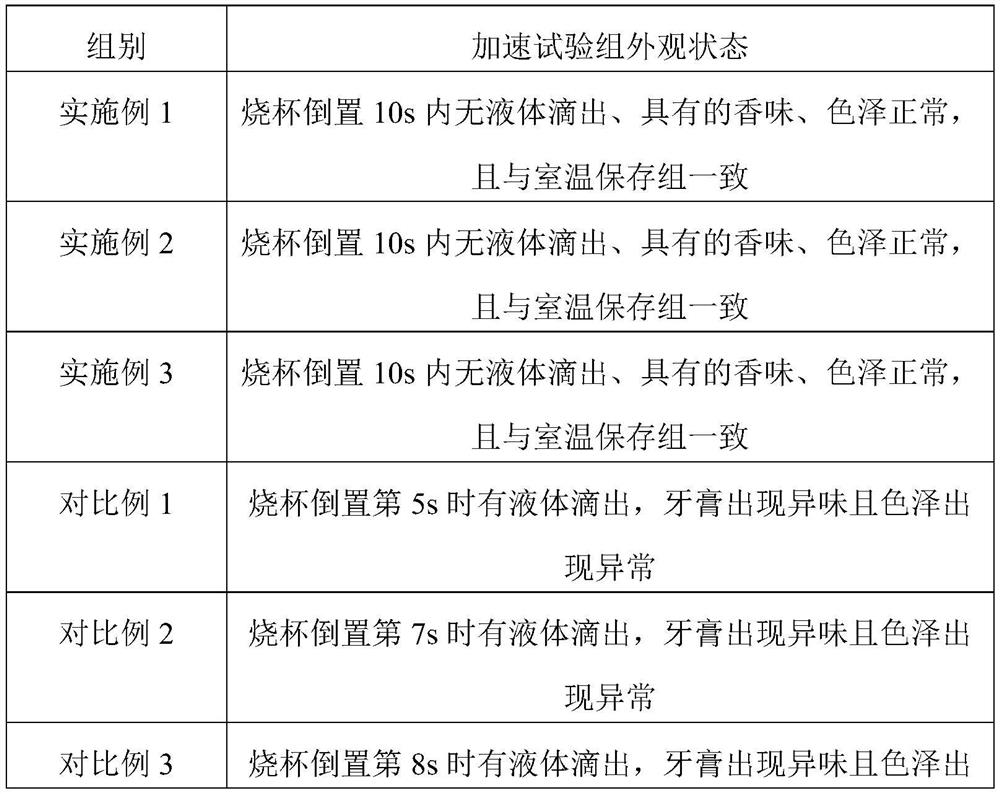

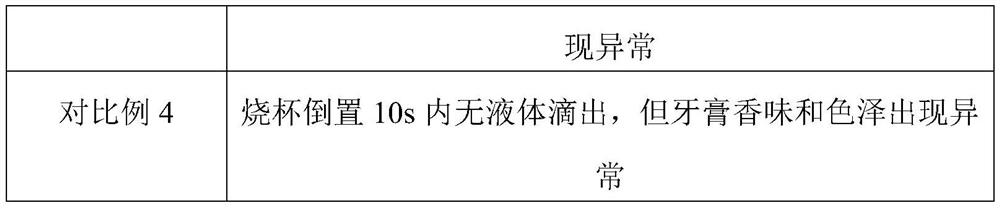

Examples

Embodiment 1

[0025] Embodiment 1, a kind of preparation method of anti-agglomeration thickening type silica

[0026] Preparation method: S1. Dilute and dissolve the water glass with a modulus of 3 with water and age for 5 hours, take the aged water glass and add water to dilute to prepare a water glass solution with a concentration of 0.35M; inject water with a concentration of 0.35M into the reaction tank Glass solution 14m 3 , heating up to 60° C., stirring, the stirring speed is 30 Hz, and adding diboron trioxide with 0.05% water glass quality, stirring and dispersing evenly to form a water glass mixed solution;

[0027] S2: Configure a sulfuric acid solution with a concentration of 3.5M to ensure that the acid solution is free from impurities;

[0028] S3: Add the sulfuric acid solution prepared in step S2 dropwise to the water glass mixed solution prepared in step S1 when the temperature is raised to 60°C, and the speed of adding the sulfuric acid solution is 2.0m 3 / h, the pH at th...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method of anti-agglomeration thickening type silica

[0031] Preparation method: S1. Dilute and dissolve water glass with a modulus of 3.3 and age for 6 hours, take the aged water glass and add water to dilute to prepare a water glass solution with a concentration of 0.45M; inject water with a concentration of 0.45M into the reaction tank Glass solution 14m 3 , heating up to 80° C., stirring, the stirring speed is 25 Hz, and adding boron trioxide with 0.1% water glass quality, stirring and dispersing evenly, forming a water glass mixed solution;

[0032] S2: Configure a sulfuric acid solution with a concentration of 3.6M to ensure that the acid solution is free from impurities;

[0033] S3: Add the sulfuric acid solution prepared in step S2 dropwise to the water glass mixed solution prepared in step S1 when the temperature is raised to 70°C, and the speed of adding the sulfuric acid solution is 2.5m 3 / h, the pH at the end of the re...

Embodiment 3

[0035] Embodiment 3, a kind of preparation method of anti-agglomeration thickening type silica

[0036] Preparation method: S1. Dilute water glass with a modulus of 3.5, dissolve and age for 8 hours, take the aged water glass and add water to dilute to prepare a water glass solution with a concentration of 0.50M; inject water with a concentration of 0.50M into the reaction tank Glass solution 14m 3 , heating up to 70° C., stirring, the stirring speed is 20 Hz, and adding boron trioxide with 0.2% water glass quality, stirring and dispersing evenly, forming a water glass mixed solution;

[0037] S2: Configure a sulfuric acid solution with a concentration of 4.0M to ensure that the acid solution is free from impurities;

[0038] S3: Add the sulfuric acid solution prepared in step S2 dropwise to the water glass mixed solution prepared in step S1 when the temperature is raised to 80°C, and the speed of adding the sulfuric acid solution is 3.0m 3 / h, the pH at the end of the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com