Polymer solid electrolyte and preparation method and application thereof

A technology of solid electrolytes and polymers, applied in the direction of solid electrolytes, electrolytes, non-aqueous electrolytes, etc., can solve problems such as poor transparency, and achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method of preparing a polymer solid electrolyte comprising the steps of:

[0034] S1. 0.9 g of polyethylene glycol double acrylate (number average molecular weight 600) is sufficiently mixed with 0.18 g of lithium perchlorate, then 0.4 g of trimethylolpropane tris (3-mercaptoacide) and 0.05 g Photo initiator 1173, finally added 0.9Gembf 4 The ionic liquid, mixed uniform, resulting in a prepolymerization system;

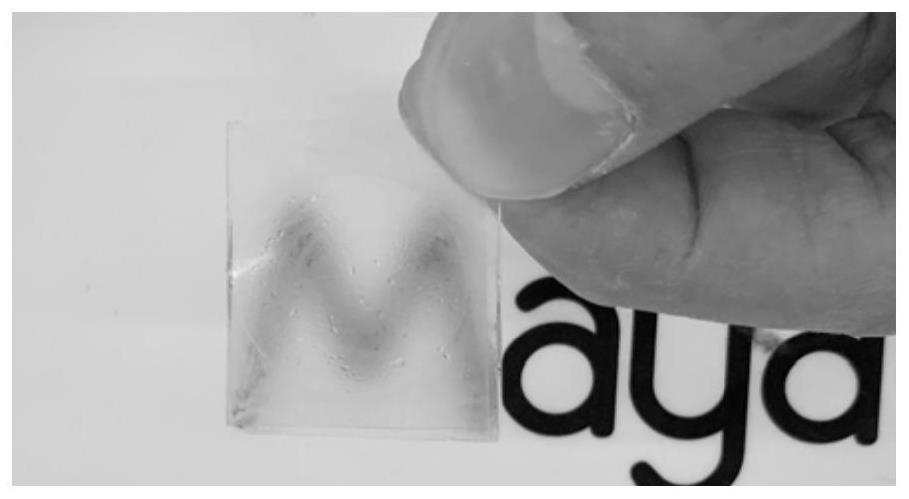

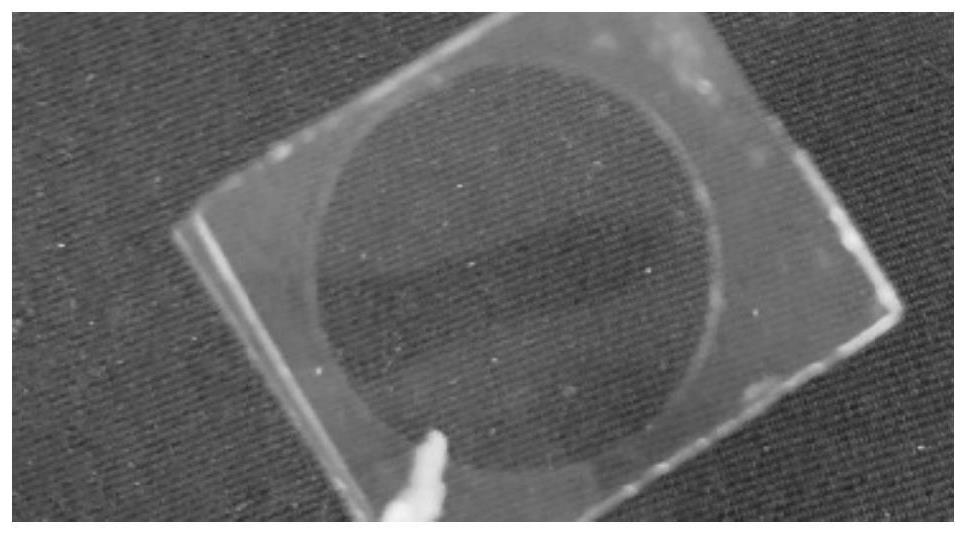

[0035] S2. The pre-polymerization system in S1 is applied to the surface of the glass sheet, and 30s is irradiated with a UV lamp having a wavelength of 365 nm to obtain a high transparent polymer solid electrolyte.

[0036] Among them, the addition of alkali metal salts is 20% of the polymer monomer; the molar ratio of the carbon carbon double bond and the crosslinking agent in the polymer monomer is 1: 1; polar solvent and polymer monomer The mass ratio is 1: 1.

Embodiment 2~9

[0038] Example 2 to 9 Preparation Method and Example 1 of the polymer solid electrolyte are substantially the same, wherein the polymer monomer, a crosslinking agent, and a polar solvent are shown in Table 1.

[0039] Table 1

[0040]

[0041] The main parameters of the first embodiment of the present invention are provided as shown in Table 2, wherein the average molecular weight of the polymer monomer; b is the percentage of the amount of the alkali metal to relative to the polymer monomer; c is a polymer single The molar ratio of carbon carbon double bonding in the body and the carbon carbon double bond or thiol group in the crosslinking agent; D is the mass ratio of the polar solvent and the polymer monomer.

[0042] Table 2

[0043] Numbering A B C D Example 1 600 20% 1:1 1:1 Example 2 200 20% 1:1.1 1:1 Example 3 2000 20% 1:1.2 1:1 Example 4 600 10% 1:1 1:1 Example 5 600 5% 1:1 1:1 Example 6 600 0.1% 1:1 1:1 E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com