Biodegradable polyester composition and application thereof

A technology of biodegradable polyester and polyester degradation, applied in the field of biodegradable polyester compositions, can solve the problems affecting the final degradation performance of products, excessive heavy metals, unsatisfactory pigment dispersion effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

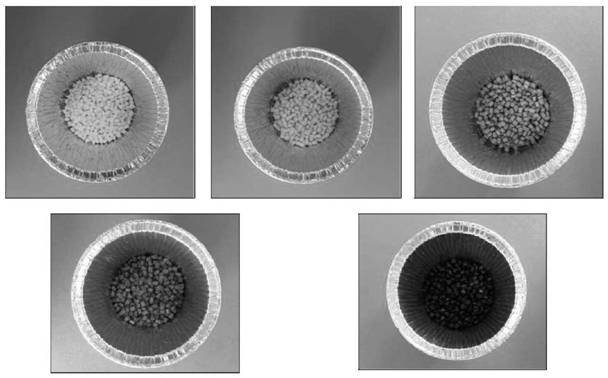

Embodiment 1

[0052] The composition of the biodegradable polyester composition (R1 white) is shown in the table below:

[0053] Table 1

[0054] raw material name Weight (unit: gram) Rutile titanium dioxide (LR-108, oil absorption value 13-17g / 100g) 25 Polylactic acid (4043D) 34 Aliphatic / Aromatic Hybrid Polyester Resin (THJS-6802) 22 Glycidyl neononanoate 1 Epoxy resin (TDE-85) 1.6 talcum powder 11 Oleamide 3.8 Ethylene bis stearamide 1.6

Embodiment 2

[0056] The composition of the biodegradable polyester composition (R2 black) is shown in the table below:

[0057] Table 2

[0058]

[0059]

Embodiment 3

[0061] The composition of the biodegradable polyester composition (R3 green) is shown in the table below:

[0062] table 3

[0063] raw material name Weight (unit: gram) Rutile titanium dioxide (LR-108, oil absorption value 13-17g / 100g) 15 Pigment yellow (2927, oil absorption value 34g / 100g) 9 Phthalocyanine blue B (oil absorption value 45g / 100g) 1 Polylactic acid (4043D) 34 Aliphatic / Aromatic Hybrid Polyester Resin (THJS-8801) 22 Glycidyl pivalate 1 Epoxy resin (TDE-85) 1.6 talcum powder 11 Oleamide 3.8 Ethylene bis stearamide 1.6

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption value | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com