Production process of wear-resistant water-based paint for spraying soft stone surface

A surface spraying, water-based coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor water resistance and wear resistance, low penetration resistance, etc., to achieve good fluidity, increase adhesion, and improve the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

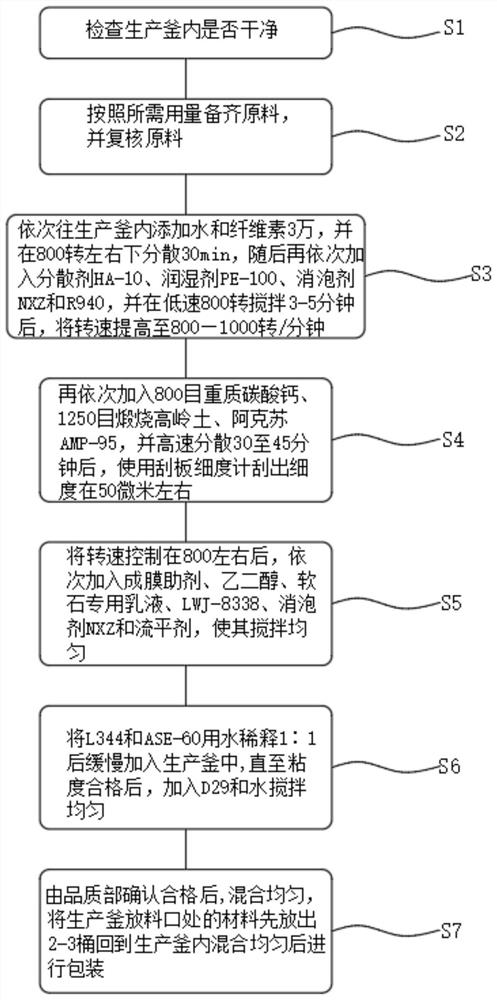

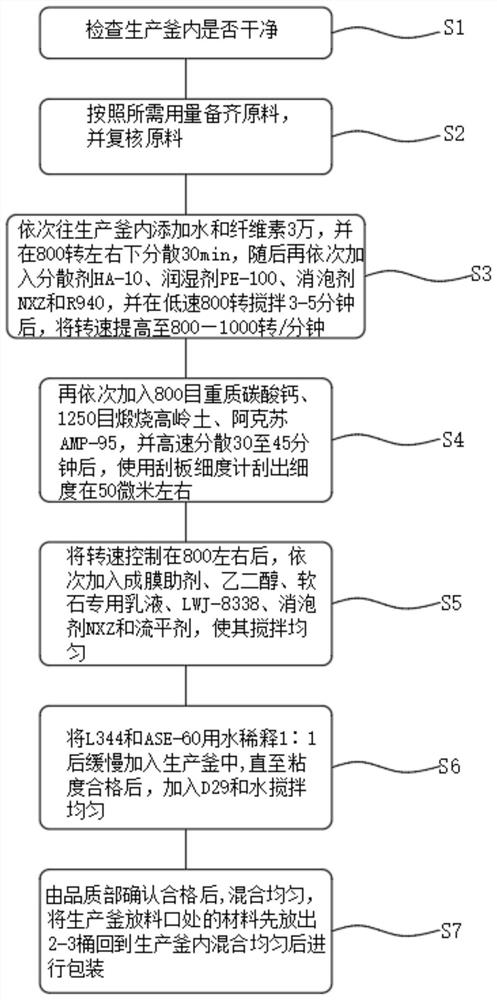

[0027] Example 1: Please refer to figure 1 , the present invention provides a kind of technical scheme: a kind of production process of wear-resistant water-based paint for soft stone surface spraying, comprising the following steps:

[0028] S1: Check whether the production kettle is clean,

[0029] S2: Prepare the raw materials according to the required amount, and review the raw materials;

[0030] S3: Add water and cellulose 30,000 to the production kettle in sequence, and disperse at about 800 rpm for 30 minutes, then add dispersant HA-10, wetting agent PE-100, defoamer NXZ and R940 in sequence, and After stirring at a low speed of 800 rpm for 3-5 minutes, increase the speed to 800-1000 rpm;

[0031] S4: Then add 800 mesh heavy calcium carbonate, 1250 mesh calcined kaolin, and Akzo AMP-95 in sequence, and disperse at high speed for 30 to 45 minutes, and use a scraper fineness meter to scrape out a fineness of about 50 microns;

[0032] S5: After controlling the rotatio...

Embodiment 2

[0036] Example 2, please refer to figure 1 , the present invention provides a technical solution: a production process of wear-resistant water-based paint for soft stone surface spraying, the specific production process is the same as the first embodiment.

[0037] The difference from Example 1 is that the raw materials in step S2 include: 23% water, 0.15% cellulose 30,000, 0.3% dispersant HA-10, 0.3% wetting agent PE-100, 0.5% disinfectant Foaming agent NXZ, 10% R940, 25% 800 mesh heavy calcium carbonate, 11.45% 1250 mesh calcined kaolin, 0.1% Akzo AMP-95, 1% film-forming aid, 1% ethylene glycol, 20% special emulsion for soft stone , 6% LWJ-8338, 0.1% defoamer NXZ, 0.1% leveling agent, 0.4% L344, 0.4% ASE-60 and 0.2% D29.

Embodiment 3

[0038] Embodiment three, please refer to figure 1 , the present invention provides a technical solution: a production process of wear-resistant water-based paint for soft stone surface spraying, the specific production process is the same as the first embodiment.

[0039] The difference from Examples 1 and 2 is that the raw materials in step S2 include: 32% water, 0.15% cellulose 30,000, 0.3% dispersant HA-10, 0.1% wetting agent PE-100, 0.4% % defoamer NXZ, 8% R940, 16.25% 800 mesh heavy calcium carbonate, 11% 1250 mesh calcined kaolin, 0.15% Akzo AMP-95, 1.5% film-forming aid, 1% ethylene glycol, 21% soft stone Special emulsion, 7% LWJ-8338, 0.15% defoamer NXZ, 0.15% leveling agent, 0.35% L344, 0.4% ASE-60 and 0.1% D29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com