Slag solidifying agent for AOD (argon oxygen decarburization) refining stainless steel smelting slag and preparation method and application thereof

A technology of argon-oxygen refining and slag coagulant, which is applied in the field of AOD argon-oxygen refining stainless steel smelting slag coagulant and its preparation, which can solve the problems of ineffective use of tailings, increased processing costs, and non-utilization of slag, reaching the price Low cost, reduced stacking cost, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

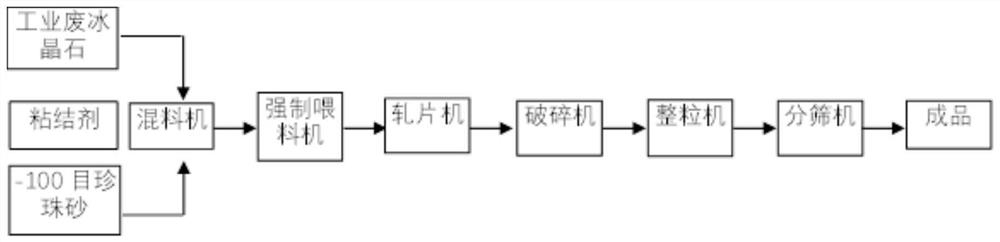

[0031] The present invention provides a method for preparing the AOD argon-oxygen refining stainless steel smelting slag coagulation agent described in the above technical solution, comprising:

[0032] Mix cryolite, binder and pearl sand to obtain a mixture;

[0033] The mixture is sequentially subjected to sheet rolling, crushing, sizing, and sieving to obtain an AOD argon-oxygen refining stainless steel smelting slag coagulation agent.

[0034] In the present invention, the cryolite is preferably industrial waste cryolite. In the present invention, the particle size of the cryolite is preferably <5 mm, more preferably 1-4 mm, most preferably 2-3 mm.

[0035] In the present invention, the binder is preferably sodium silicate, more preferably sodium silicate dry powder.

[0036] In the present invention, the particle size of the pearl sand is preferably <5 mm, more preferably 0.5-2 mm, most preferably 1-1.5 mm; the particle size of the pearl sand is preferably -100 mesh.

...

Embodiment 1

[0060] according to figure 1 In the shown process, industrial waste cryolite, sodium silicate dry powder and pearl sand are mixed to obtain a mixture;

[0061] The mixture is sequentially subjected to sheet rolling, crushing, sizing, and sieving to obtain an AOD argon-oxygen refining stainless steel smelting slag coagulation agent with a particle size of 0.5-2 mm.

[0062] The mass ratio of industrial waste cryolite and pearl sand (-100 mesh) is 20:80; the mass of sodium silicate dry powder is 1.5% of the mass of the mixture.

[0063] Using the GB / T14506 "Chemical Analysis Method for Silicate Rocks" standard, the AOD argon-oxygen refining stainless steel smelting slag coagulation agent prepared in Example 1 of the present invention is tested for composition, and the test result is: SiO 2 : 58.46wt%; Al 2 o 3 : 9.95wt%; Fe 2 o 3 : 2.17wt%; CaO: 0.69wt%; K 2 O: 2.03wt%; Na 2 O: 3.65wt%; MgO: 0.24wt%; H 2 O: 3.54wt%; NaF 9.47wt%; AlF 3 8.52wt%; CaF 2 1.06wt%; MgF 2 ...

Embodiment 2

[0066] according to figure 1 In the shown process, industrial waste cryolite, sodium silicate dry powder and pearl sand are mixed to obtain a mixture;

[0067] The mixture is sequentially subjected to sheet rolling, crushing, sizing, and sieving to obtain an AOD argon-oxygen refining stainless steel smelting slag coagulation agent with a particle size of 0.5-2 mm.

[0068] The mass ratio of industrial waste cryolite and pearl sand (-100 mesh) is 30:70; the mass of sodium silicate dry powder is 1.5% of the mass of the mixture.

[0069] According to the method of Example 1, the composition of the AOD argon oxygen refining stainless steel smelting slag coagulant prepared in Example 2 of the present invention is detected, and the test result is: SiO 2 : 51.15wt%; Al 2 o 3 : 8.83wt%; Fe 2 o 3 : 2.23wt%; CaO: 0.6wt%; K 2 O: 1.78wt%; Na 2 O: 3.2wt%; MgO: 0.21wt%; H 2 O: 3.1wt%; NaF 14.2wt%; AlF 3 12.77wt%; CaF 2 1.59wt%; MgF 2 0.34 wt%.

[0070] Add 1 / 3 of the slag coag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com