Zinc volatilization kiln flue gas high-temperature dust collection and waste heat utilization device

A zinc volatilization and flue gas technology is applied in the field of high-temperature dust collection and waste heat utilization devices for flue gas of zinc volatilization kilns, to achieve the effects of improving smoke exhaust efficiency, inhibiting rapid loss, and enhancing absorption rate and heat transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

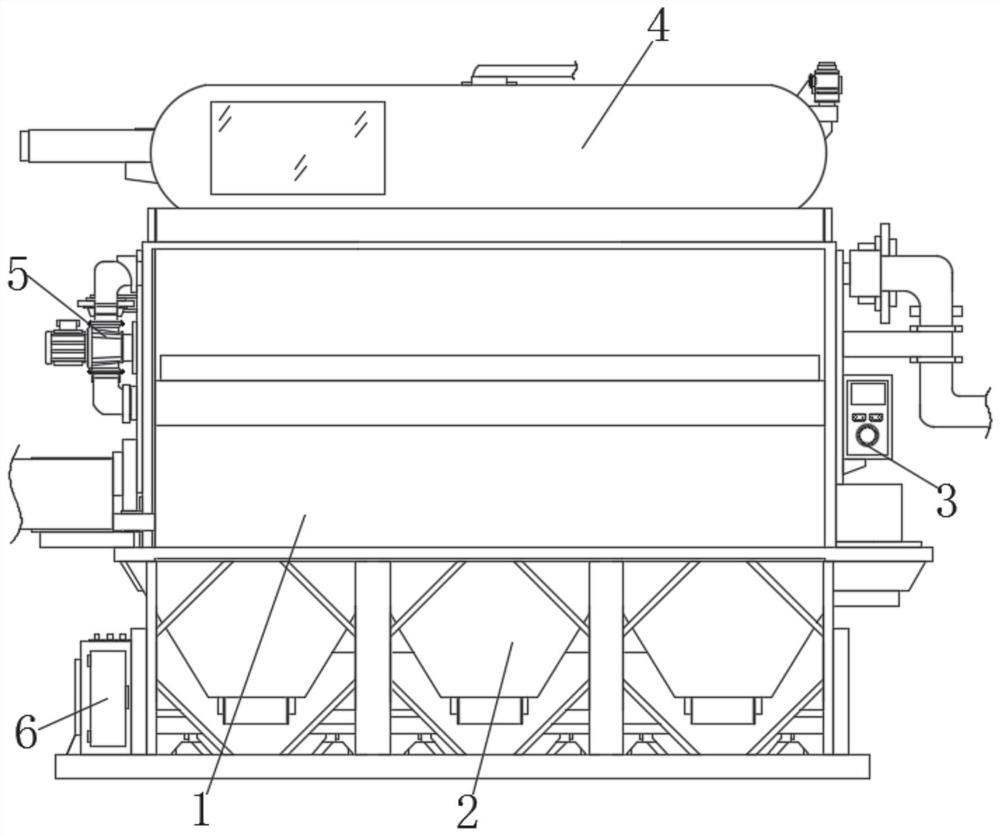

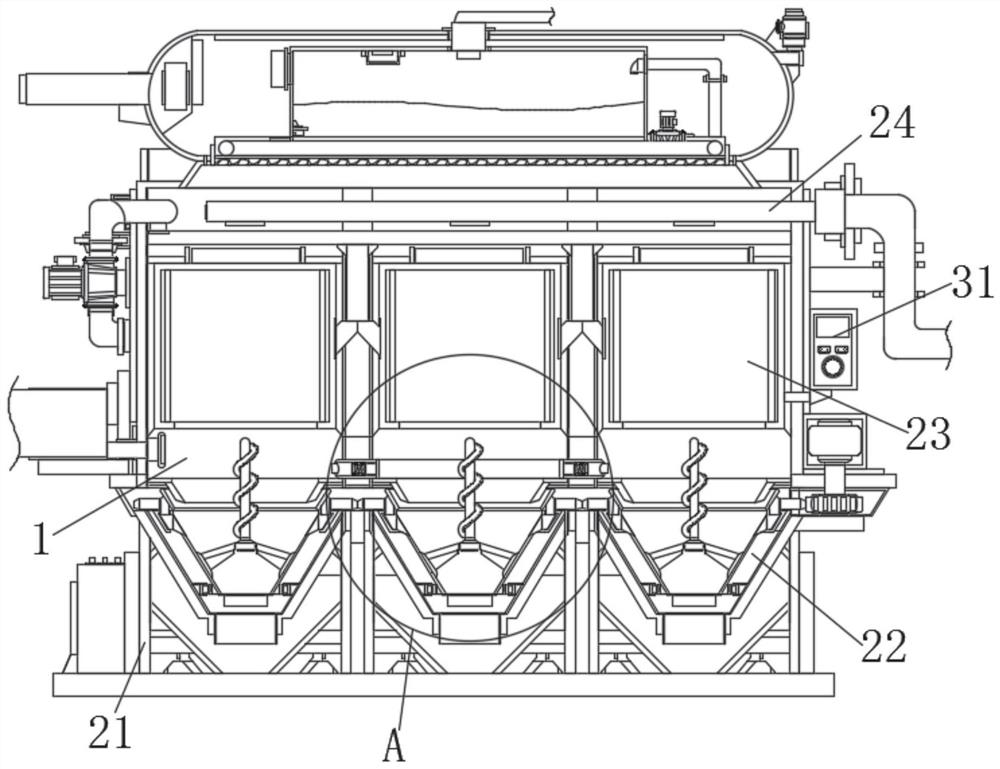

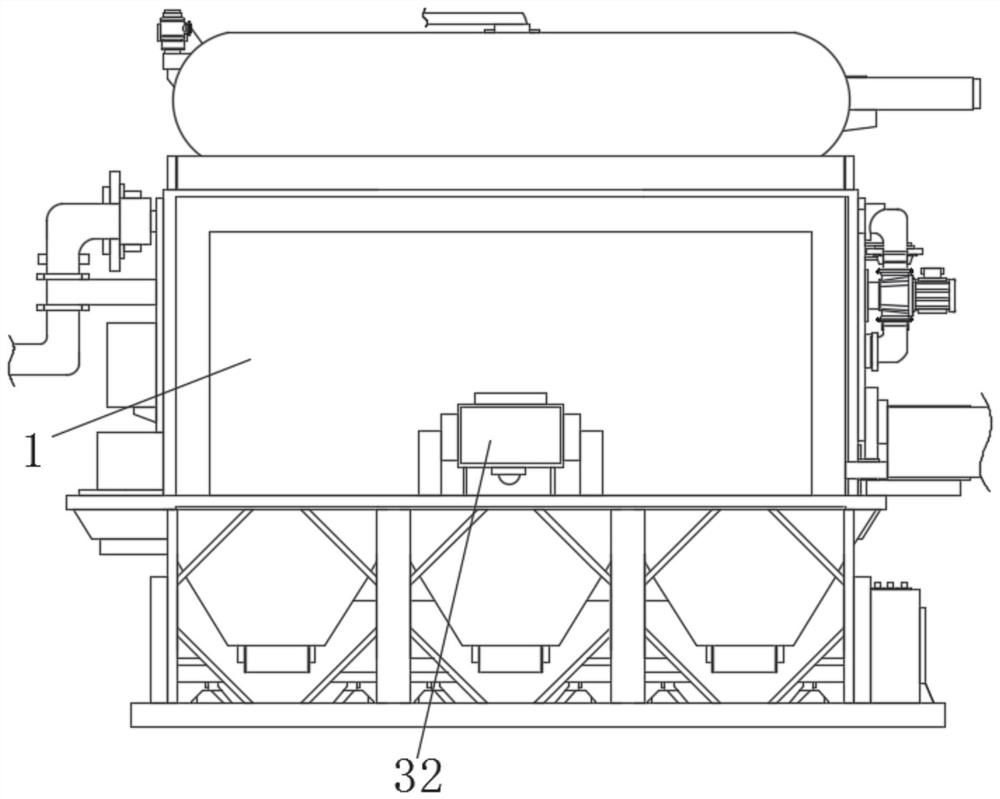

[0043] Example 1, such as Figure 1-4 As shown, when the temperature in the warehouse body 1 is not up to the standard through the temperature monitor 31, the fan 32 and the annular electric heating wire 34 can be intelligently controlled to start, and the heating of the annular electric heating wire 34 is used to promote the heat to be concentrated in the annular cavity 33. The start of the blower fan 32 can form a guide wind to spray the heated heat evenly from the through hole 35, and then effectively and quickly heat the warehouse body 1, so as to promote the normal maintenance of the smoke dust collection heat of the warehouse body 1, so as to prevent The dust is bonded into agglomerates under the influence of large temperature difference fluctuations, which increases the active heating effect of the device.

Embodiment 2

[0044] Example 2, such as Figure 6-7 As shown, when the water pump 47 is started to pump the water in the water tank 46 into the diversion pipe 45 for waste heat utilization, the water level sensor can sense the water volume in the water tank 46, and when the water volume forms hot steam loss under the waste heat utilization structure , just can automatically fill into the water tank 46 by the water supply pipe, forming the recycling of the preheating and combustion-supporting system, so that the water liquid in the water tank 46 dries up completely, increasing the intelligent control effect of the device.

[0045] Working principle: when the device is in use, high-temperature flue gas can be introduced into the bin body 1, during which the pulse dust removal system 5 and the flue gas dust collection mechanism 2 are respectively activated through the console 6, and when the pulse dust removal system 5 is started, the bin body 1 The dust-removing filter element 23 inside carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com