Method for preparing hydroxyapatite nano rod by using egg white template

A technology of hydroxyapatite and nanorods, applied in the direction of nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve problems such as obstacles, affecting the development of hydrothermal reactions, and strong dependence on production equipment, achieving high performance and advancing Commercialization process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

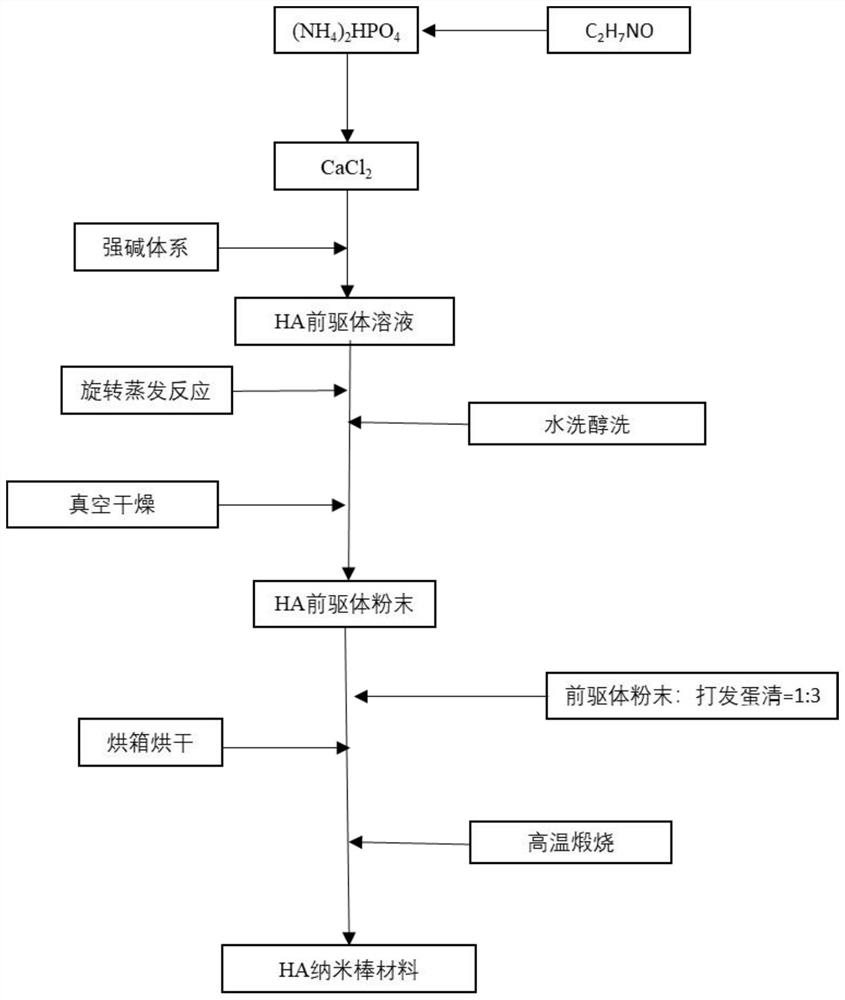

Method used

Image

Examples

Embodiment 1

[0035] Step 1, prepare calcium salt solution: weigh 7.226g CaCl 2 In a beaker, add 30mL of deionized water and stir for 10min with a magnetic stirrer to obtain a calcium salt solution;

[0036] Step 2, prepare ethanolamine solution: weigh 0.764g C 2 h 7 NO and add 20mL of deionized water, and stir for 10min with a magnetic stirrer to obtain ethanolamine solution;

[0037] Step 3, prepare mixed solution: weigh 5.002g (NH 4 ) 2 HPO 4 Add it to the ethanolamine solution obtained in step 2, and stir for 10 minutes using a magnetic stirrer to obtain a mixed solution;

[0038] Step 4, preparing an alkaline solution: Weigh 5.208g of NaOH powder, add the weighed NaOH powder to 20mL deionized water five times, and stir for 10min with a magnetic stirrer to obtain an alkaline solution;

[0039] Step 5, adding the mixed solution and alkaline solution obtained in step 3 and step 4 to the calcium salt solution obtained in step 1 in sequence, and stirring for 30 minutes to obtain a whi...

Embodiment 2

[0044] Step 1, prepare calcium salt solution: weigh 14.452g CaCl 2 In a beaker, add 50mL of deionized water and stir for 20min with a magnetic stirrer to obtain a calcium salt solution;

[0045] Step 2, prepare ethanolamine solution: weigh 1.527g C 2 h 7 NO and add 40mL deionized water, and stir for 15min with a magnetic stirrer to obtain ethanolamine solution;

[0046] Step 3, prepare mixed solution: weigh 10.005g (NH 4 ) 2 HPO 4 Add to the ethanolamine solution obtained in step 2, and stir for 20 minutes using a magnetic stirrer to obtain a mixed solution;

[0047] Step 4, preparing an alkaline solution: Weigh 10.417g of NaOH powder, add the weighed NaOH powder to 30mL deionized water 8 times, and stir for 20min with a magnetic stirrer to obtain an alkaline solution;

[0048] Step 5, adding the mixed solution and alkaline solution obtained in step 3 and step 4 to the calcium salt solution obtained in step 1 in sequence, stirring for 45 minutes to obtain a white emulsio...

Embodiment 3

[0053] Step 1, prepare calcium salt solution: weigh 28.904g CaCl 2 In a beaker, add 100mL deionized water and stir for 30min with a magnetic stirrer to obtain a calcium salt solution;

[0054] Step 2, prepare ethanolamine solution: weigh 3.054g C 2 h 7 NO and add 70mL of deionized water, and stir for 20min with a magnetic stirrer to obtain ethanolamine solution;

[0055] Step 3, prepare mixed solution: weigh 20.009g (NH 4 ) 2 HPO 4 Add to the ethanolamine solution obtained in step 2, and stir for 30 minutes using a magnetic stirrer to obtain a mixed solution;

[0056] Step 4, prepare alkaline solution: weigh 20.833g NaOH powder, add the weighed NaOH powder 10 times into 50mL deionized water, and stir for 30min with a magnetic stirrer to obtain an alkaline solution;

[0057] Step 5, adding the mixed solution and alkaline solution obtained in step 3 and step 4 to the calcium salt solution obtained in step 1 in sequence, and stirring for 60 minutes to obtain a white emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com