Pretreatment method of digital printing fabric with water-repellent and antifouling functions

A digital printing and pretreatment technology, which is applied in the field of printing and dyeing, can solve the problems of unclear pattern edges, poor color fastness of paint and ink combination, etc., and achieve the improvement of anti-seepage effect, improvement of the overall wearing performance of fabrics, and improvement of printing suitability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

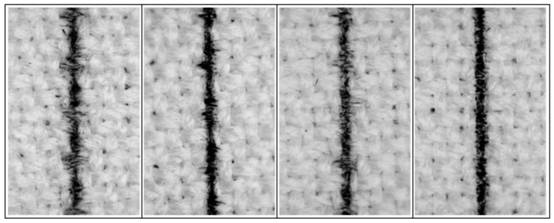

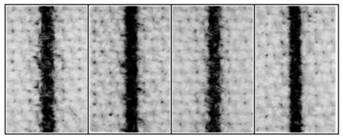

Image

Examples

Embodiment 1

[0027] A method for pretreatment of digitally printed fabrics with water-repellent and antifouling functions, comprising the following steps:

[0028] Step 1): configure the cationic modifier pretreatment solution, and let it stand at room temperature; the mass concentration of the cationic modifier pretreatment solution is 1%, and the cationic modifier is an ammonium chloride polymer;

[0029] Step 2): Prepare a fluorine-containing water-repellent agent solution and add it to the cationic modifier pretreatment solution, heat and stir in a water bath, and mix evenly; the mass concentration of the fluorine-containing water-repellent agent solution is 0.05%, and the heating temperature of the water bath is 80°C;

[0030] Step 3): The mixed solution obtained in step 2) is used to process the fabric by two dipping and two rolling methods; specifically, the horizontal padding car is used to process the fabric, and the time of soaking in the mixed solution is 40 minutes each time, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com