Flexible piezoresistive sensor based on porous microstructure and preparation method thereof

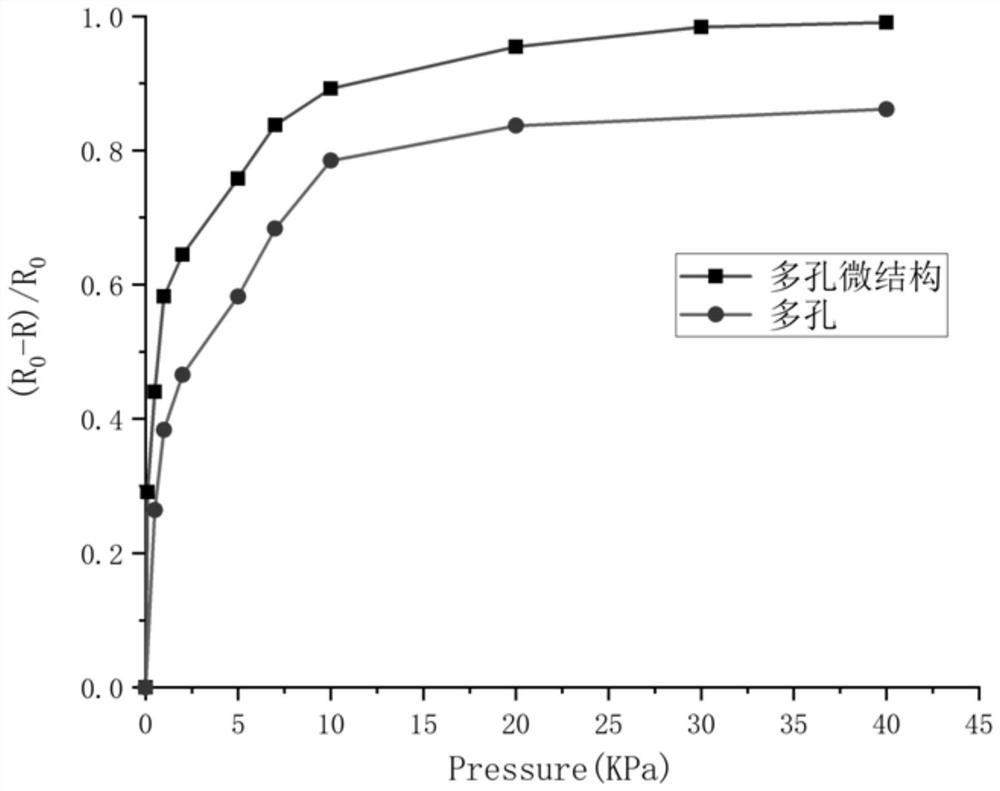

A microstructure and piezoresistive technology, which is applied in the measurement of the property force of piezoresistive materials, etc., can solve the problem of less sensitivity of the conductive path, and achieve the effects of low cost, improved conductive path and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

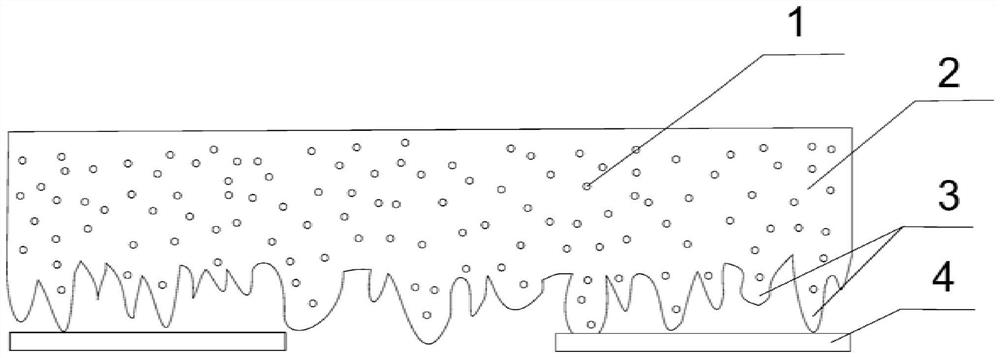

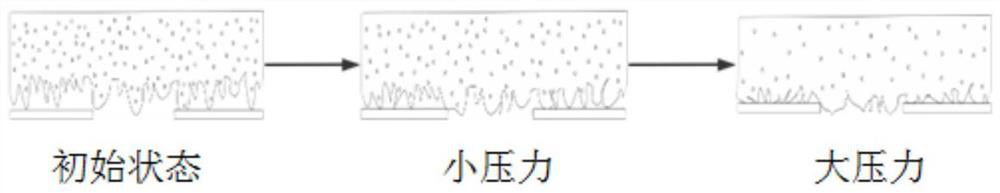

[0028] Such as Figure 1-Figure 2 A flexible piezoresistive sensor based on a porous microstructure shown includes a flexible substrate 1 and an interdigital electrode 4 arranged below the flexible substrate 1; the upper surface of the flexible substrate 1 is a plane, and the lower surface is provided with several directions A protruding microstructure 3; several micropores 2 are opened on the flexible base 1.

[0029] Further, the flexible substrate adopts PDMS (polydimethylsiloxane), curing agent, conductive filler and PET powder (polyethylene terephthalate) according to 10:1:a:(0.8~1.2) It is prepared by mixing the ratio of a, wherein, the value range of a is 1-1.5.

[0030] Further, the conductive filler is any one or a combination of carbon black, graphene, and carbon nanotubes.

[0031] Further, a part of the microstructure is in contact with the top of the interdi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com