Quantum dot light emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as the instability of the hole functional layer film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

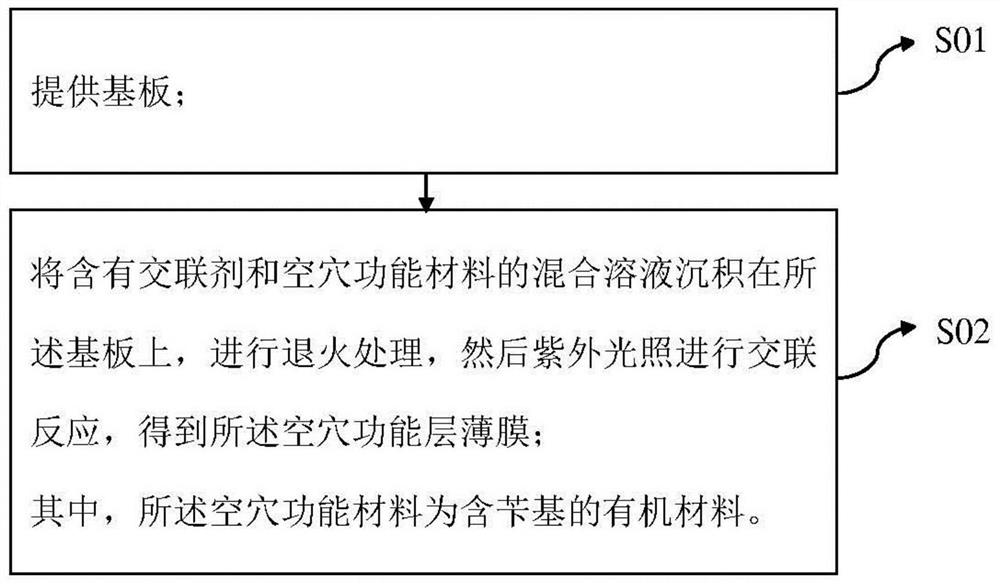

[0020] On the one hand, the embodiment of the present invention provides a method for preparing a quantum dot light-emitting diode, such as figure 1 Shown, this preparation method comprises the steps:

[0021] S01: Provide the substrate;

[0022] S02: Depositing a mixed solution containing a crosslinking agent and a hole function material on the substrate, performing annealing treatment, and then performing a crosslinking reaction under ultraviolet light to obtain a hole function layer;

[0023] Wherein, the hole functional material is an organic material containing a benzyl group.

[0024] In the preparation method of the quantum dot light-emitting diode provided in the embodiment of the present invention, a mixed solution containing a crosslinking agent and a hole functional material is deposited on a substrate for annealing treatment, and then ultraviolet light is irradiated for a crosslinking reaction to obtain a hole functional layer. During the ultraviolet irradiation ...

Embodiment 1

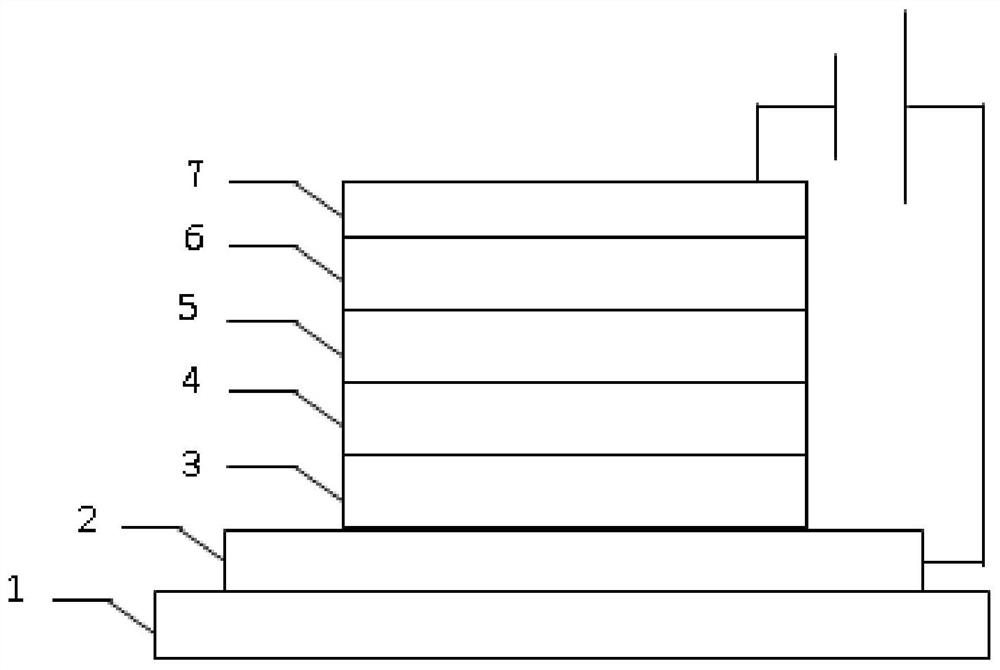

[0061] This embodiment provides a QLED device, its structure is as follows figure 2 As shown, the QLED device includes a substrate 1 , an anode 2 , a hole injection layer 3 , a hole transport layer 4 , a quantum dot light-emitting layer 5 , an electron transport layer 6 , and a cathode 7 sequentially from bottom to top. Among them, the material of the substrate 1 is a glass sheet, the material of the anode 2 is an ITO substrate, the material of the hole injection layer 3 is PEDOT:PSS, and the material of the hole transport layer 4 is 2-hydroxy-4-methoxydiphenyl Ketone and poly[(9,9-dioctylfluorenyl-2,7-diyl)-alt-(4,4′-(N-(4-n-butyl)phenyl)-diphenylamine) ], the material of the quantum dot light-emitting layer 5 is CdZnSe / ZnSe / ZnS red quantum dots, the material of the electron transport layer 6 is ZnO, and the material of the cathode 7 is Al.

[0062] The preparation method of the device comprises the following steps:

[0063] Spin-coat the hole injection layer PEDOT:PSS mat...

Embodiment 2

[0065] This embodiment provides a QLED device, its structure is as follows figure 2 As shown, the QLED device includes a substrate 1 , an anode 2 , a hole injection layer 3 , a hole transport layer 4 , a quantum dot light-emitting layer 5 , an electron transport layer 6 , and a cathode 7 sequentially from bottom to top. Among them, the material of the substrate 1 is a glass sheet, the material of the anode 2 is an ITO substrate, the material of the hole injection layer 3 is PEDOT:PSS, and the material of the hole transport layer 4 is 2-hydroxy-4-n-octyloxydi Benzophenone and poly(9-vinylcarbazole), the material of the quantum dot light-emitting layer 5 is CdZnSe / ZnSe / ZnS red quantum dots, the material of the electron transport layer 6 is ZnO, and the material of the cathode 7 is Al.

[0066] The preparation method of the device comprises the following steps:

[0067] Spin-coat the hole injection layer PEDOT:PSS material on the anode ITO, then anneal at 100°C for 15min; then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com