S-type heterojunction catalyst as well as preparation method and application thereof

A catalyst and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, carbon monoxide, etc., can solve problems such as unsatisfactory catalytic effects, achieve improved CO generation rate, low cost, and high light utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

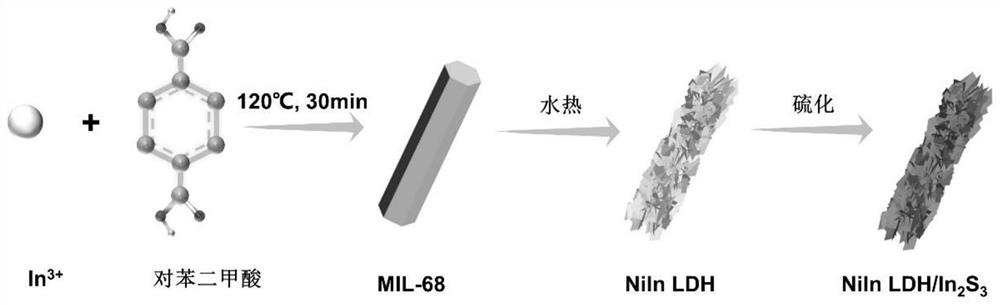

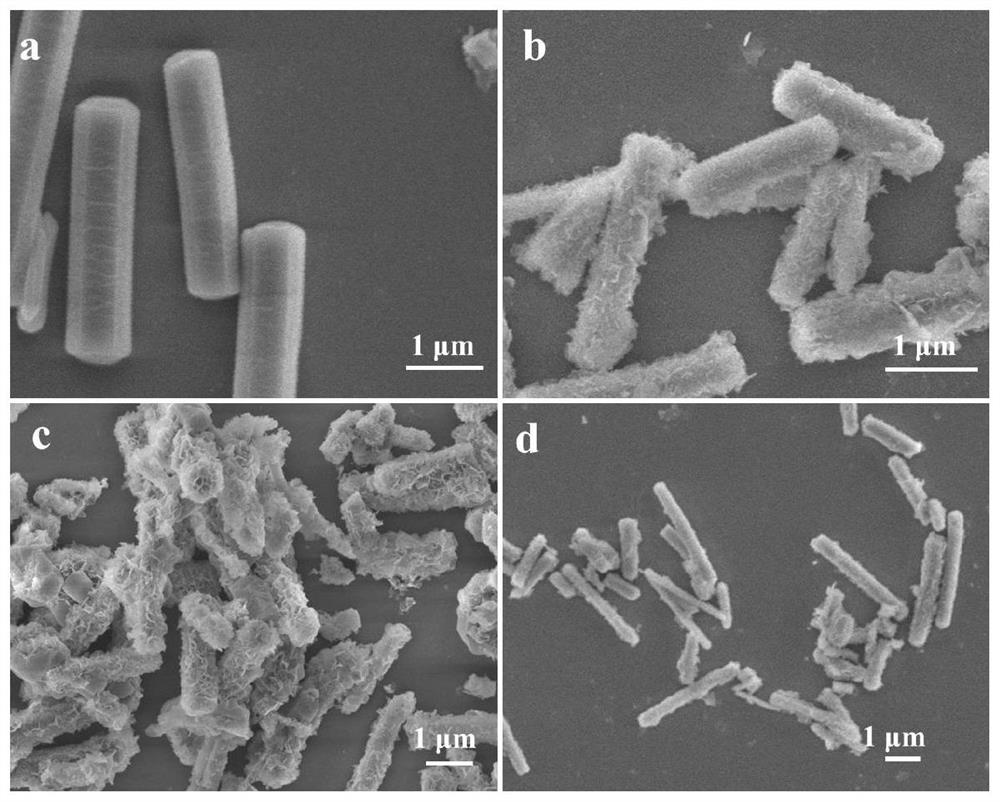

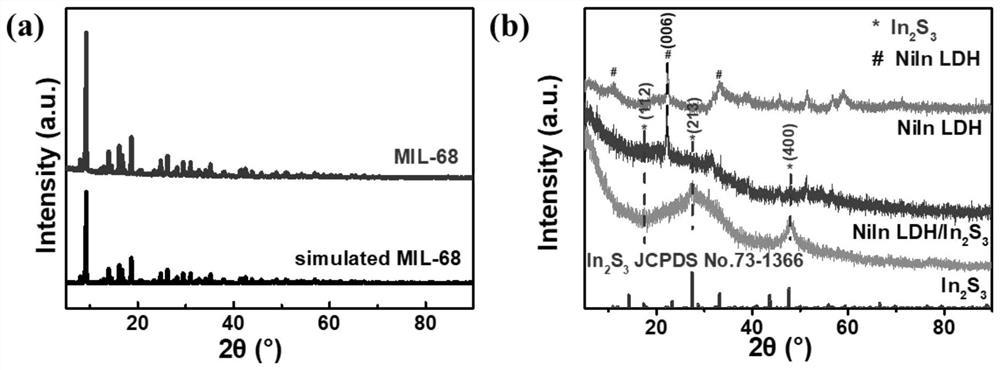

[0051] Synthesis of MIL-68(In) Catalyst

[0052] Take 60mg In(NO 3 ) 3 ·xH 2 O and 60mg of terephthalic acid were dissolved in 40mL of N,N-dimethylformamide solution, stirred vigorously for 5min; then, the solution was placed in an oil bath at 120°C for 30min, filtered by vacuum, and washed with deionized water and ethanol Washed three times respectively to obtain a white precipitate; dried in vacuum at 60°C for 24 hours to obtain MIL-68(In).

Embodiment 2

[0054] Synthesis of NiIn LDH catalyst

[0055] Get the MIL-68(In) that 120mgS1 obtains and disperse in 20mL 0.1M NaOH solution to obtain mixed solution A, 360mg Ni(NO 3 ) 2 ·6H 2 O was dissolved in 20mL deionized water to obtain mixed solution B. Mix mixed solution A and mixed solution B thoroughly, transfer to a 50mL polytetrafluoroethylene-lined stainless steel reactor, and keep the reaction at 180°C for 12h; after cooling to room temperature, vacuum Suction filtration and washing with deionized water and ethanol three times respectively to obtain a green precipitate; vacuum drying at 60°C for 24 hours to obtain NiInLDH.

Embodiment 3

[0057] Synthesis of S-Type Heterojunction NiIn LDH / In 2 S 3 catalyst

[0058] Take 60mg of the obtained NiIn LDH and disperse it in 40mL of ethanol, add 60mg of thiourea under vigorous stirring, continue to stir vigorously for 30min, then transfer to a 50mL polytetrafluoroethylene liner stainless steel reactor, keep the reaction at 100°C for 2h, cool to room temperature , vacuum-filtered, and washed with deionized water and ethanol three times respectively to obtain a gray precipitate; vacuum-dried at 60°C for 24 hours to obtain NiIn LDH / In 2 S 3 . The schematic diagram of its reaction principle is shown in figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com