Method for preparing high-quality single crystal domain two-dimensional material by regulating and controlling cavity pressure

A two-dimensional material, high-quality technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., to achieve the effects of easy popularization and application, compatible growth equipment, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

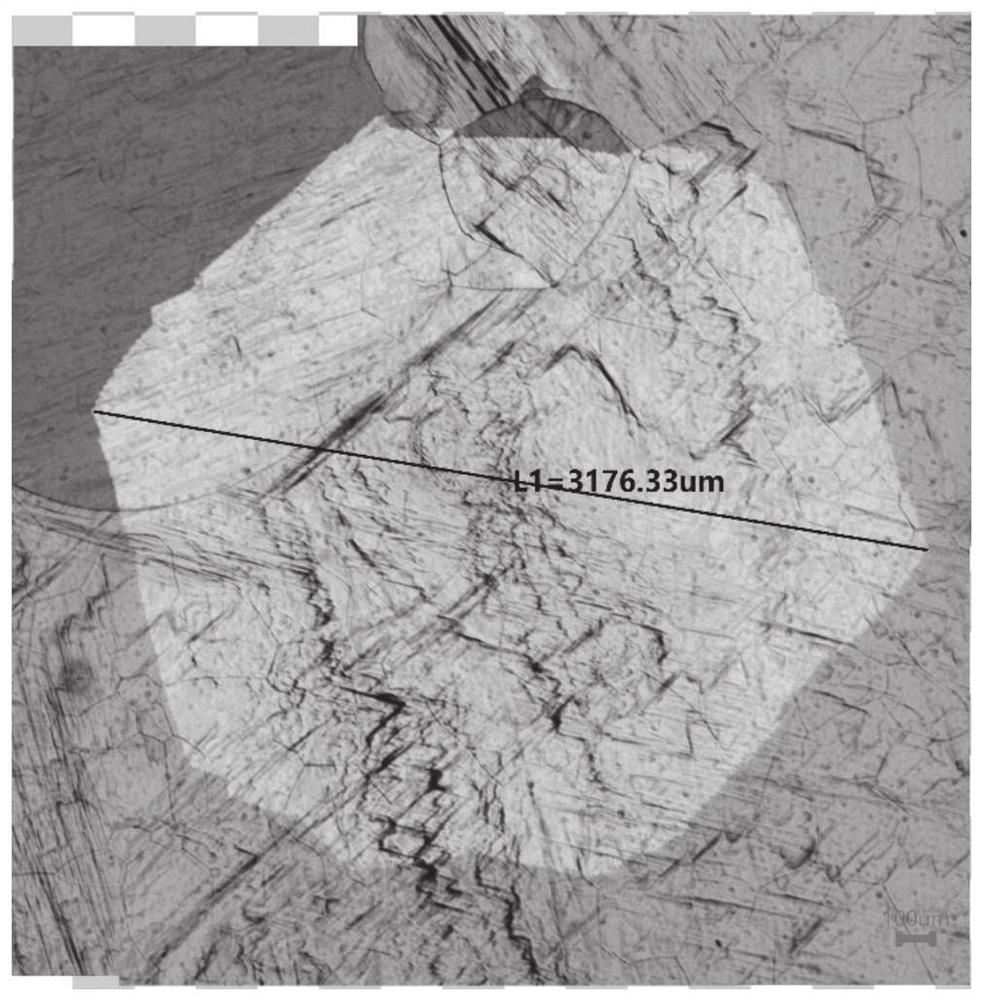

[0060] A method for preparing single-crystal domain graphene by regulating furnace pressure, comprising steps as follows:

[0061] (1) Select metal copper Cu as the substrate, and electrochemically polish it, wash it with deionized water, and heat it at 200°C for 30min for pre-oxidation treatment;

[0062] (2) Place the pretreated Cu substrate in the reaction furnace chamber, and then vacuumize the furnace chamber to 5×10 -5 Pa; close the vacuum pump unit, feed the inert gas Ar, until the furnace chamber pressure is 1 atm, then open the vacuum pump unit, pump and charge the furnace chamber, repeat 3 times, and carry out vacuum treatment to the furnace chamber;

[0063] (3) Introduce Ar, maintain the pressure of the furnace body at 0.5atm, raise the temperature to 1050°C in an argon atmosphere of 500 sccm (milliliters per minute), and then infuse H 2 (20 sccm), adjust the furnace pressure to 0.75 atm, and pre-anneal the substrate for 60 min.

[0064] (4) Adopt one-thousandth ...

Embodiment 2

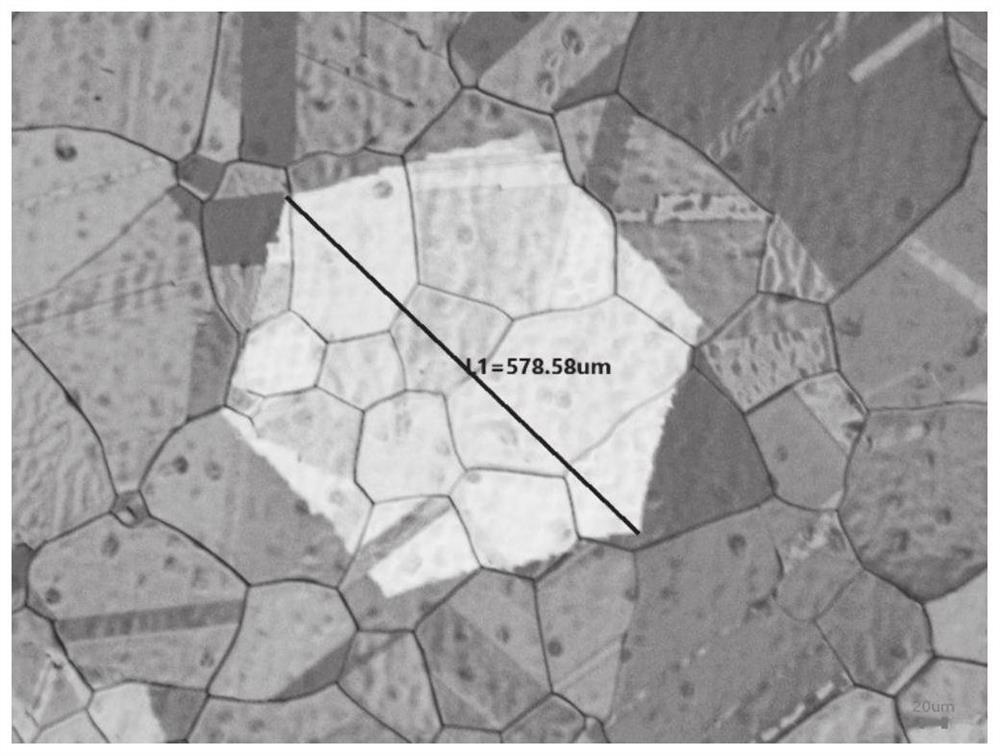

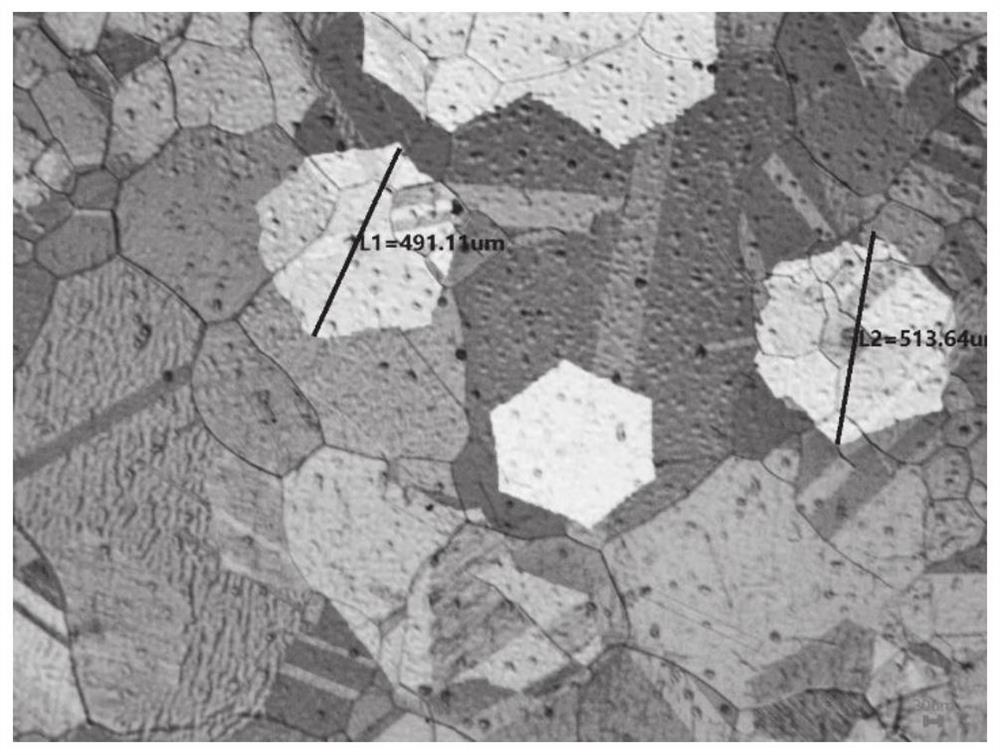

[0075] A preparation of high-quality single-crystal two-dimensional MoSe 2 The material method comprises the following steps:

[0076] (1) Evaporate 300nm thick SiO on a commercial Si wafer 2 layer, and is evaporated with SiO 2 One side of the layer is polished as a substrate;

[0077] (2) Treated Si / SiO 2 The substrate is placed in the furnace chamber, and the polishing surface is aligned with MoO 3 Precursor; the Se powder precursor is placed in front of the substrate with a distance of 20cm;

[0078] (3) The furnace cavity is vacuumed, and the vacuum degree is not higher than 5×10 -5 Pa; turn off the vacuum pump unit, feed inert background gas until the furnace cavity pressure is 1 atm, then turn on the vacuum pump unit, pump and charge the furnace cavity, repeat 3 times, and carry out vacuum treatment to the furnace cavity;

[0079](4) Pass 50sccm Ar and 5sccm H 2 The mixed gas is used as the carrier gas, the furnace pressure is adjusted to 0.5atm, and different tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com