Method for inducing surface metallicity of lithium niobate by laser

A laser-induced, surface metal technology, applied in the usage of superconductor elements, chemical instruments and methods, single crystal growth, etc., can solve the problems of easy introduction of impurities, inconvenient regulation, etc., to avoid high temperature and low vacuum environment, and the preparation process is simple. Efficient and easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

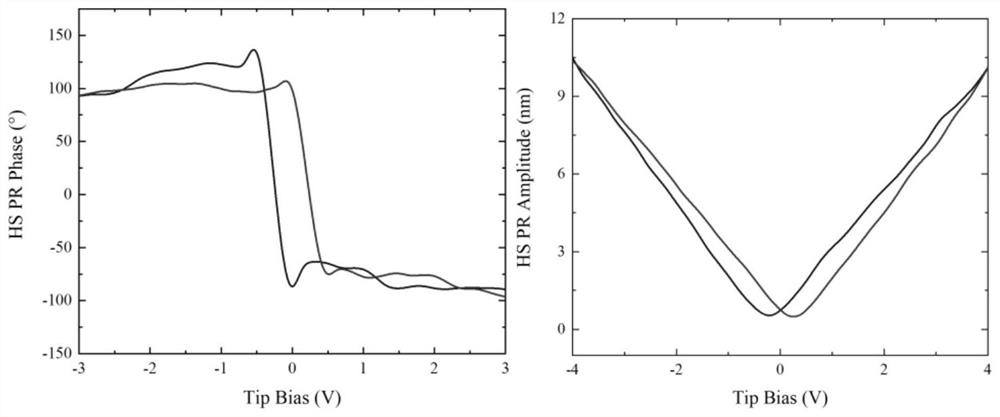

[0031] A method for laser-induced surface metallicity of lithium niobate, comprising the following steps:

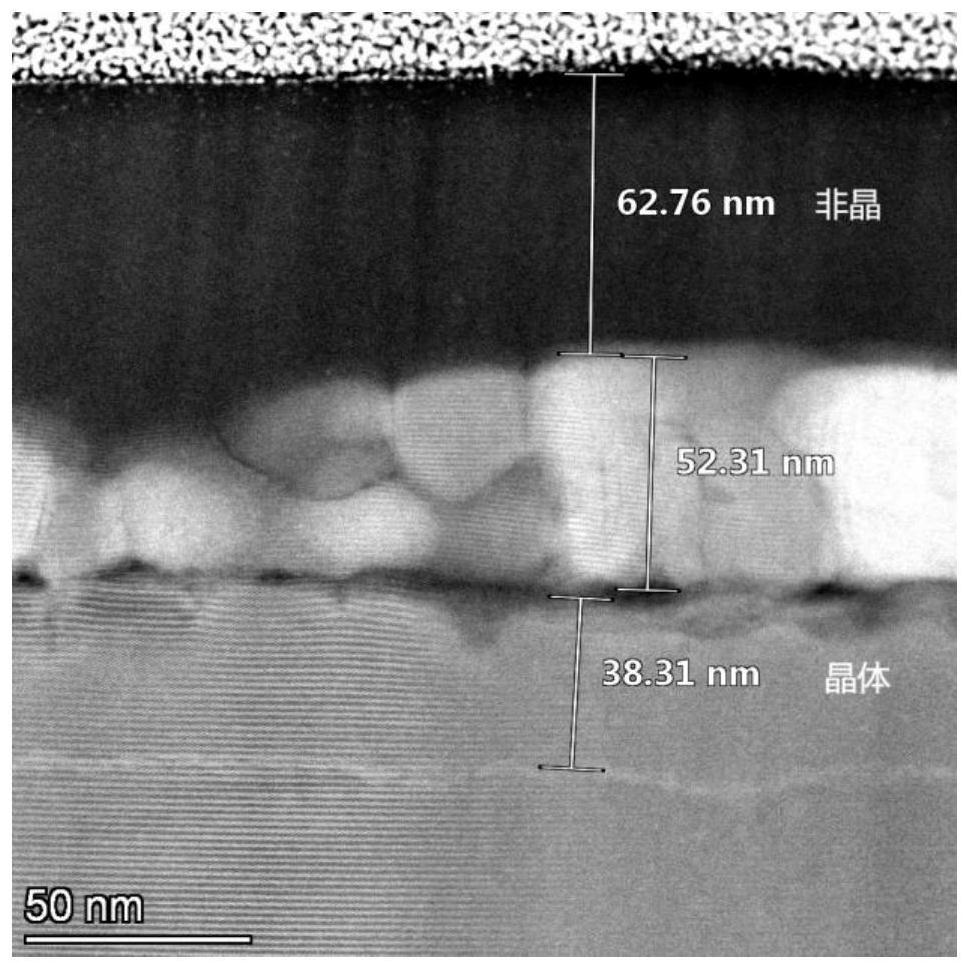

[0032] 1) Pretreatment: Choose lithium niobate crystals with orientation , size 5*5*0.5mm, immerse in 99% ethanol solution for ultrasonic cleaning for 10 minutes, and then air dry naturally.

[0033] 2) Setting the preparation environment: fix the cleaned lithium niobate crystal in a vacuum chamber, and adjust the laser irradiation surface of the lithium niobate to be 90° with the laser incident direction. First vacuum the vacuum chamber to 1*10 -3 Pa, and then pass oxygen into the cavity, so that the vacuum degree reaches 5*10 -3 Pa.

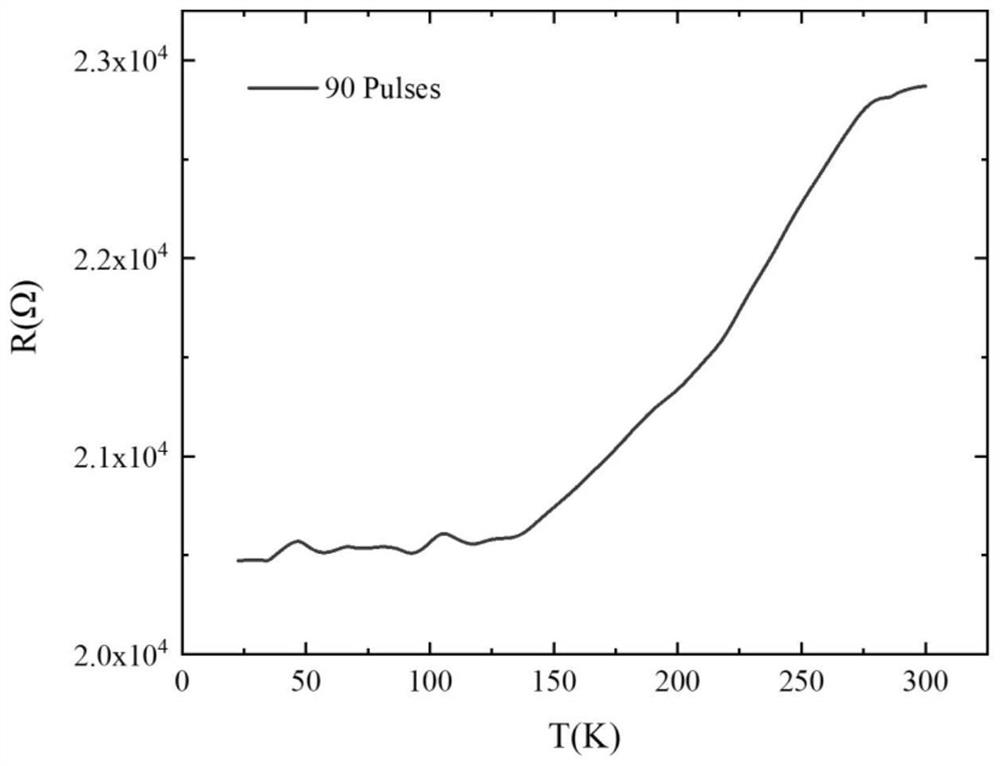

[0034] 3) Laser irradiation: First, adjust the laser parameters, set the pulse laser energy to 115mJ, the wavelength of 248nm, and the frequency of 1Hz. Load the pulsed laser so that the entire surface of the lithium niobate is completely exposed in the center of the spot, and let the laser irradiate the surface of the lithium niobate ...

Embodiment 2

[0040] Compared with Embodiment 1, the difference between this embodiment is that in step 3), the laser pulse time is 15s, that is, 15 pulses of laser light, and the rest of the steps are the same as those in Embodiment 1.

Embodiment 3

[0042] Compared with Embodiment 1, the difference between this embodiment is that in step 3), the laser pulse time is 30s, that is, 30 pulses of laser light, and the rest of the steps are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com