Large-diameter deep shaft reverse tunneling device and construction method

A construction method and large-diameter technology, applied in shaft equipment, reverse sinking, safety devices, etc., can solve problems such as breakage of driving rods, formation vibration, easy eccentricity, etc., and achieve the effect of reducing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

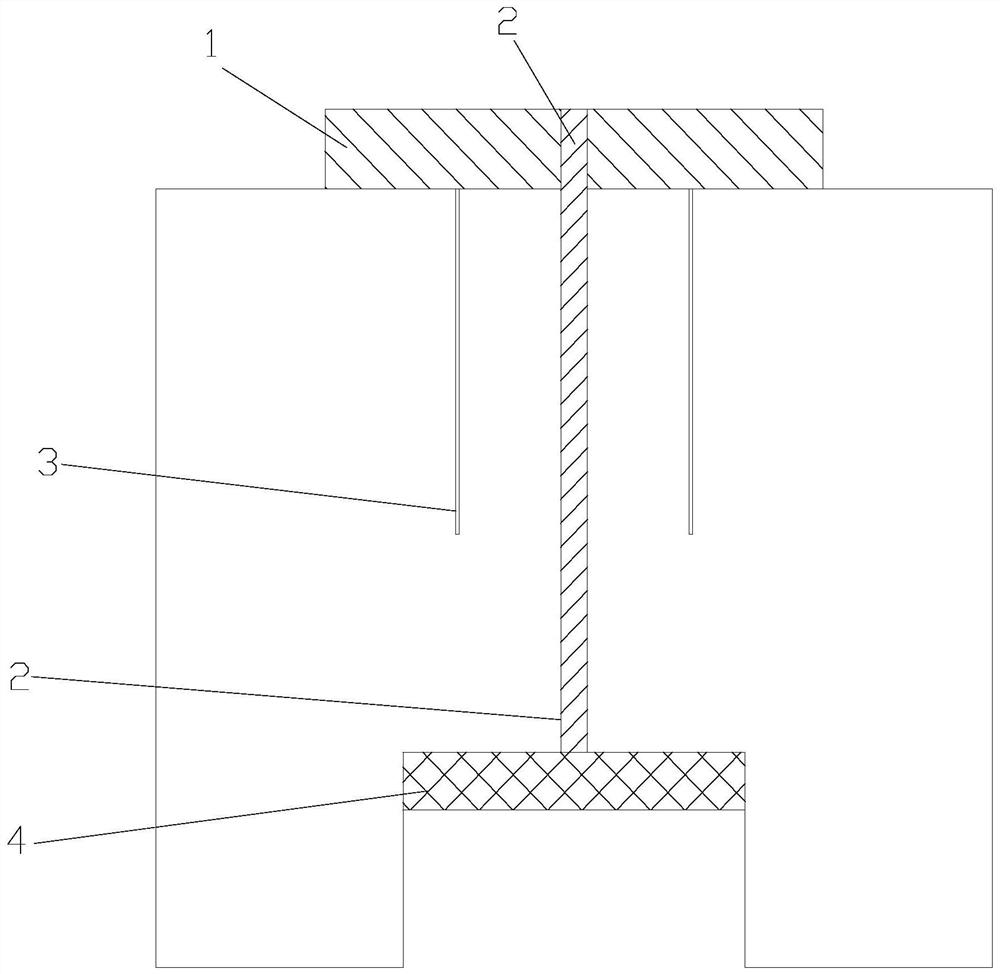

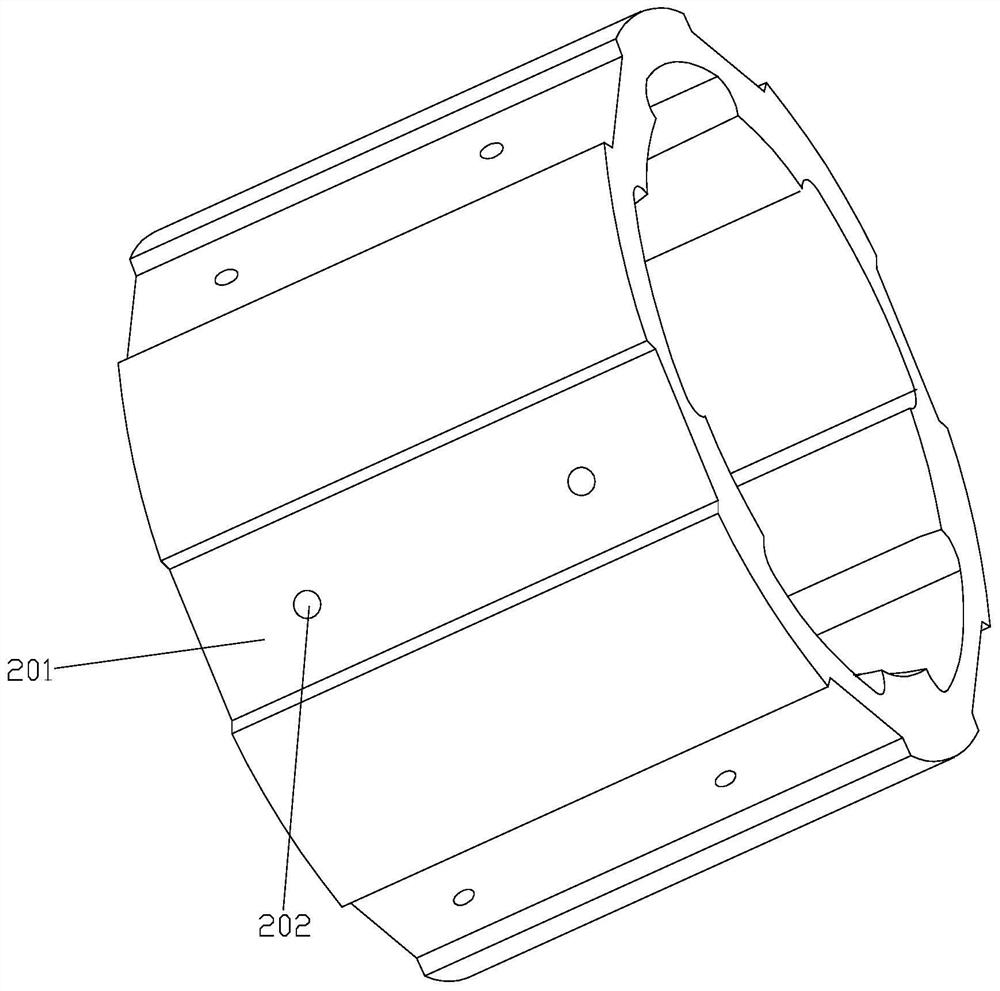

[0044] See attached figure 1 and attached figure 2 , a large-diameter deep shaft reverse driving device, including an excavation drill bit 4, a rotary lifting drive assembly 1 and a drill pipe 2, and the two ends of the drill pipe 2 are detachably matched with the excavation drill bit 4 and the rotary lifting drive assembly 1 respectively. Together, the drill rod 2 is a cylindrical drill rod 2, and the wall of the drill rod 2 is provided with a notch groove 201, the notch groove 201 is parallel to the central axis of the drill rod 2, there are multiple notch grooves 201, and the notch groove 201 They are distributed equidistantly and equiradially around the central axis of the drill pipe 2 .

[0045] In this embodiment, the drill rod 2 is a drill rod 2 made of a metal alloy.

[0046] In this embodiment, the number of notch grooves 201 is an even number, and the notch grooves 201 are arc-shaped notch grooves 201 .

[0047] In this embodiment, the drill rod 2 is a hollow dri...

Embodiment 2

[0051] See attached figure 1 and attached figure 2 , a kind of construction method using the large-diameter deep well reverse boring device as embodiment, comprises the steps:

[0052] S1: Determine the pre-excavation center point, excavate several buried holes around the pre-excavation center point, the buried holes are distributed equidistantly around the pre-excavation center point, and the distance between the central axis of the pre-excavation hole and the pre-excavation center point is 40cm. The diameter of the buried hole is 6cm, and the accumulated water in the pre-dug hole is sucked away, and the buried hole is blown dry with airflow. The buried hole is a counterbore; circle;

[0053] S2: Fill the buried hole with dry and non-agglomerated cement powder;

[0054] S3: Excavate the pre-excavation hole at the center point of the pre-excavation. During the excavation process, water is continuously poured into the pre-excavation hole to lubricate and cool down until the...

Embodiment 3

[0064] A construction method for excavating a large-diameter vertical deep well for an underwater tunnel;

[0065] First build the cofferdam, the cofferdam is located above the tunnel, then drain the accumulated water in the cofferdam, dig out the silt in the cofferdam, and then install the steps described in Example 2 for operation.

[0066] The underwater tunnel described in this embodiment may be a subsea tunnel, a river crossing tunnel, or a lake bottom tunnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com