Heat treatment method for improving fatigue performance of selective laser melting alpha-beta type titanium alloy

A technology of laser selective melting and heat treatment, which is applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve the problems of low fatigue performance, reduce fatigue performance and stability of titanium alloy parts, and achieve improved fatigue performance , short heat treatment cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. In the various drawings and the following description, well-known structures and techniques have not been shown in order to avoid unnecessarily obscuring the present invention.

[0032] Adopt method of the present invention to carry out heat treatment step to TC4 titanium alloy as follows:

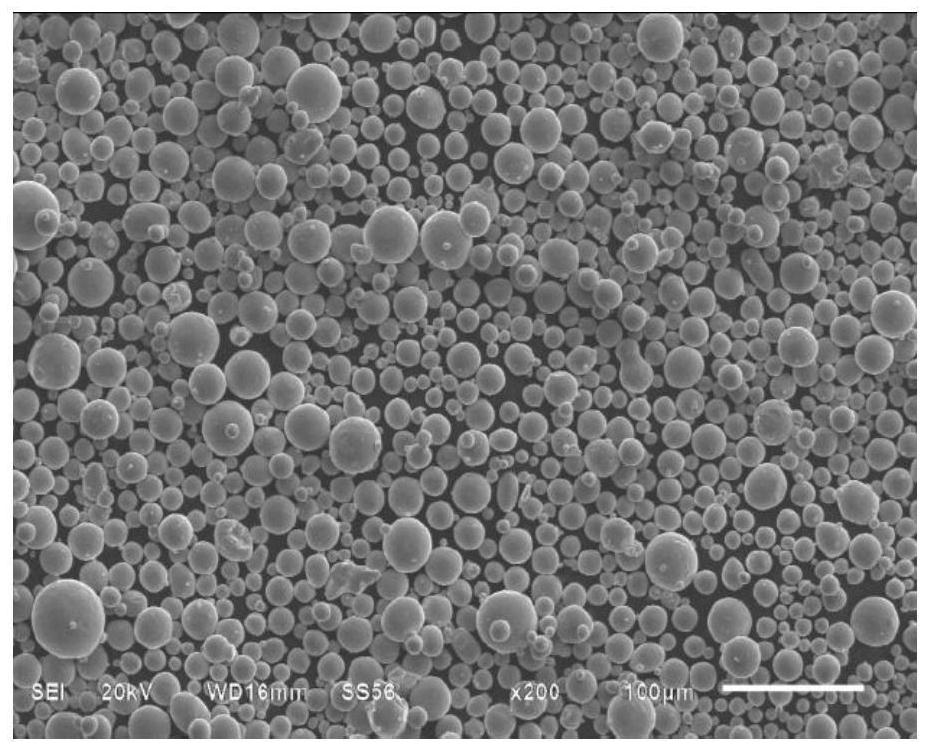

[0033] 1. The TC4 titanium alloy powder raw material is prepared by gas atomization method. The particle size range of the powder is 15-53μm, the fluidity is 32s / 50g, and the appearance is shown in figure 1 .

[0034] 2. Design 25 fatigue samples (φ14×70mm) and 6 tensile samples (φ12×71mm) to be evenly distributed on the substrate, and form in the direction perpendicular to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com