Large-diameter high-pressure zirconium coating pressure vessel as well as manufacturing method and application thereof

A pressure vessel and manufacturing method technology, applied in pressure vessels, manufacturing tools, fixed-capacity gas storage tanks, etc., can solve the problem that the manufacturing process cannot meet the actual needs of large-diameter high-pressure zirconium-clad pressure vessels, and solve the problem of vessel strength. , The effect of simple combination and mature manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

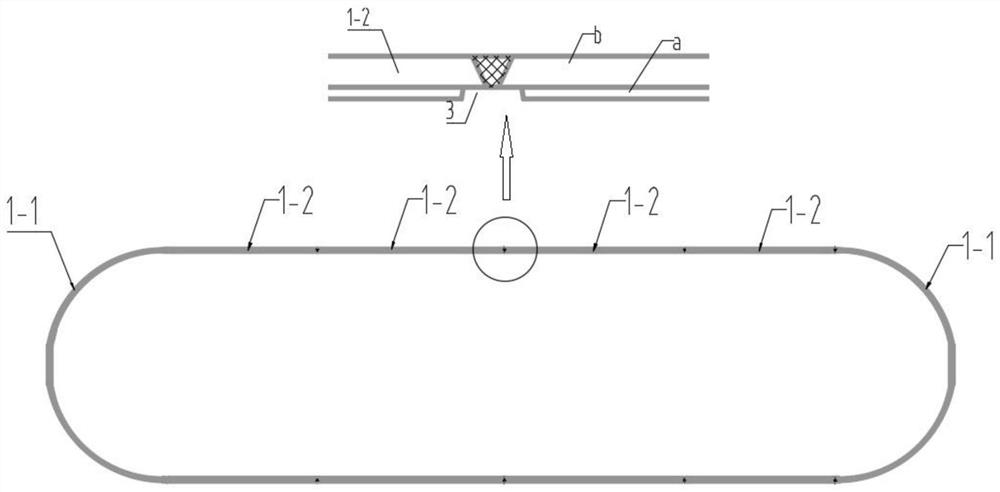

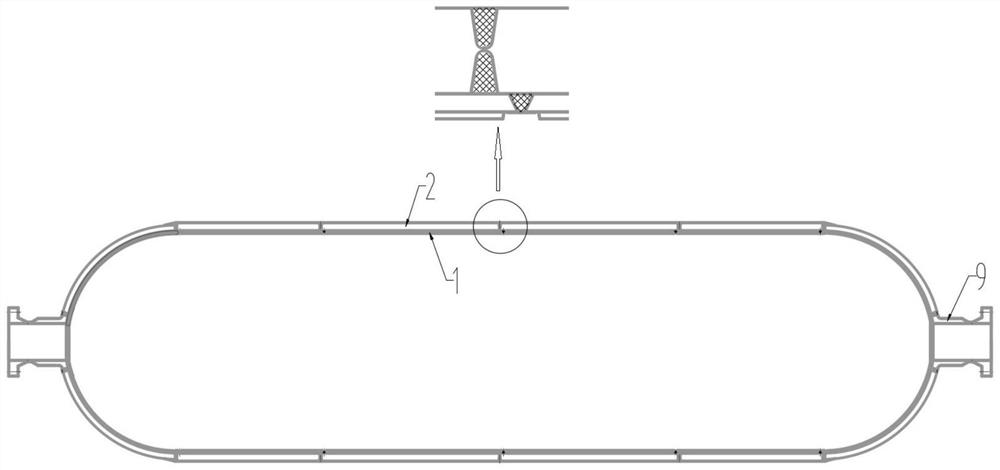

[0077] A large-diameter high-pressure zirconium-clad pressure vessel, comprising an inner cylinder 1 and an outer cylinder 2 set outside the inner cylinder 1;

[0078] The material of the inner cylinder 1 is a zirconium composite plate, wherein the zirconium coating a of the zirconium composite plate is located inside the inner cylinder 1; the inner cylinder 1 includes an inner head 1- 1 and the inner cylinder section 1-2; welding between the inner head 1-1 and the inner cylinder section 1-2 and between two adjacent inner cylinder sections 1-2; specific welding The method is that a zirconium cladding is provided at the welding joint between the inner layer head 1-1 and the inner layer cylinder section 1-2 or between two adjacent inner layer cylinder sections 1-2 Gap 3: The inner layer cylinder section 1-2 is welded to the inner layer head 1-1 or the base layer b of the zirconium composite plate at the joint between two adjacent inner layer cylinder sections 1-2.

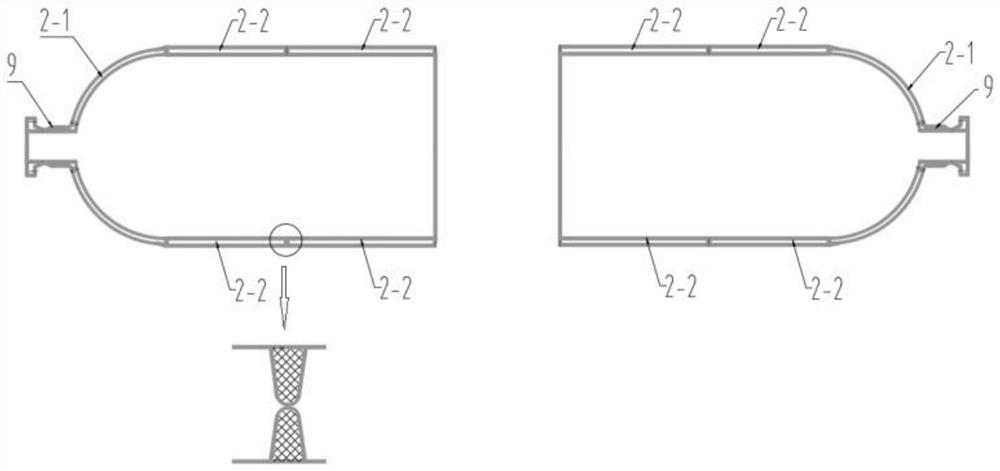

[0079] The ...

Embodiment 2

[0084] This embodiment introduces its process hole on the basis of Embodiment 1.

[0085] One or more process holes are provided at the corresponding positions of the inner cylinder body 1 and the outer layer cylinder body 2; the process holes can be used as import and export of materials, and can also be used as manholes.

[0086] Such as Figure 7 with Figure 8 As shown, a zirconium adapter 8 and a forging flange 9 are installed on the process hole; the forging flange 9 includes an integrally forged connection part 9-1 and a flange part 9-2; the connection part 9-1 The free end is welded on the outer cylinder 2; the zirconium adapter 8 is attached to the inner wall of the forging flange 9; one end of the zirconium adapter 8 is welded on the inner wall of the inner cylinder 1 , and the other end is fixedly connected with the flange part 9-2.

[0087] A concave groove 10 is opened on the plane of the flange part 9-2; a zirconium composite plate is welded and filled in the ...

Embodiment 3

[0092] A method for manufacturing a large-diameter high-pressure zirconium-clad pressure vessel, comprising the following steps:

[0093] Process 1: Manufacturing the inner cylinder

[0094] The zirconium composite board is made of zirconium / titanium / steel three-layer composite board (Zr-3 / TA1 / Q345R B0); the zirconium composite board includes the zirconium cladding a and the base layer b; the composite board is ultrasonically retested before entering the factory, Ⅰ grade qualified. After passing the inspection, carry out scribing-cutting-rolling / stamping, and manufacture the zirconium composite plate into the inner layer cylinder section 1-2 and the inner layer head 1-1 respectively; the inner layer cylinder section 1-2 and the The zirconium coating a of the zirconium composite plate at the junction of the inner layer head 1-1 is removed to form a zirconium coating gap 3, and then the inner layer cylinder section 1-2 is connected to the inner layer head 1-1 Base layer b weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com