Rapid polishing device for transformer bushing and working method of rapid polishing device

A technology of transformer bushing and polishing device, applied in grinding/polishing safety device, grinding drive device, grinding/polishing equipment, etc. Handling and other problems, to achieve the effect of adjustable polishing speed, good environmental protection effect and fast polishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

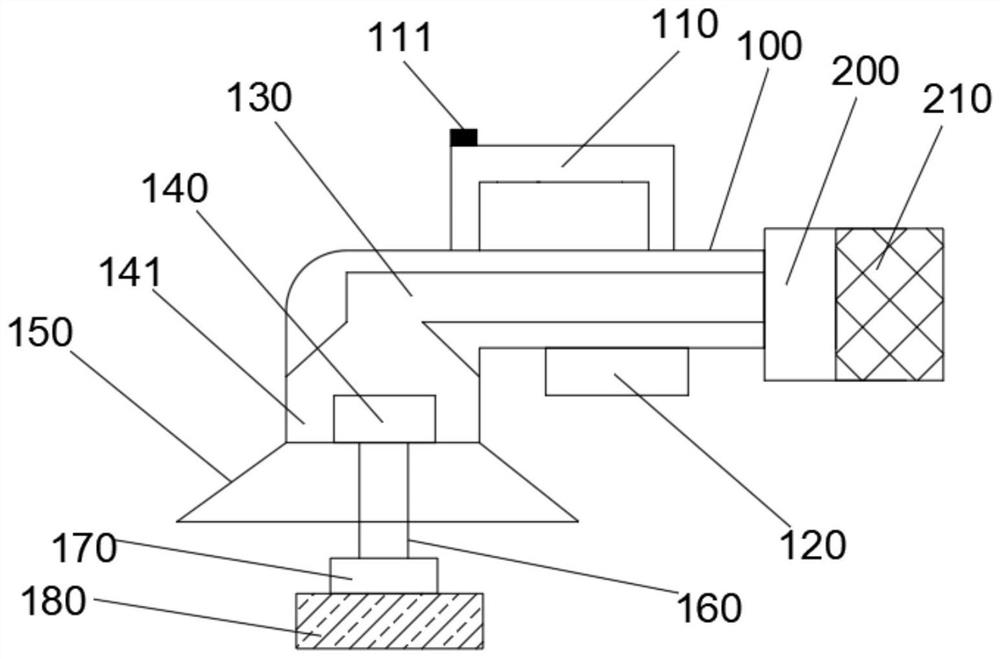

[0022] as attached figure 1 A rapid polishing device for transformer bushings is shown, including an L-shaped device body 100, a handle 110, a two-stage switch 111, a battery compartment 120, an internal air pipe 130, a motor 140, a dust suction channel 141, a dust collection cover 150, Transmission rod 160, polishing rack 170, polishing sheet 180, air pump 200, dust collection box 210; the head of the L-shaped device body 100 is equipped with the dust collection cover 150; the dust collection cover 150 is trumpet-shaped; The L-shaped device body 100 is provided with the handle 110; the handle 110 is provided with a two-stage switch 111; the battery compartment 120 is arranged below the L-shaped device body 100; the L-shaped device The body 100 is provided with the internal air pipe 130; the dust collecting cover 150 is provided with the motor 140; a dust suction channel 141 is left between the motor 140 and the internal air pipe 130; the motor 140 The transmission rod 160 is...

Embodiment 2

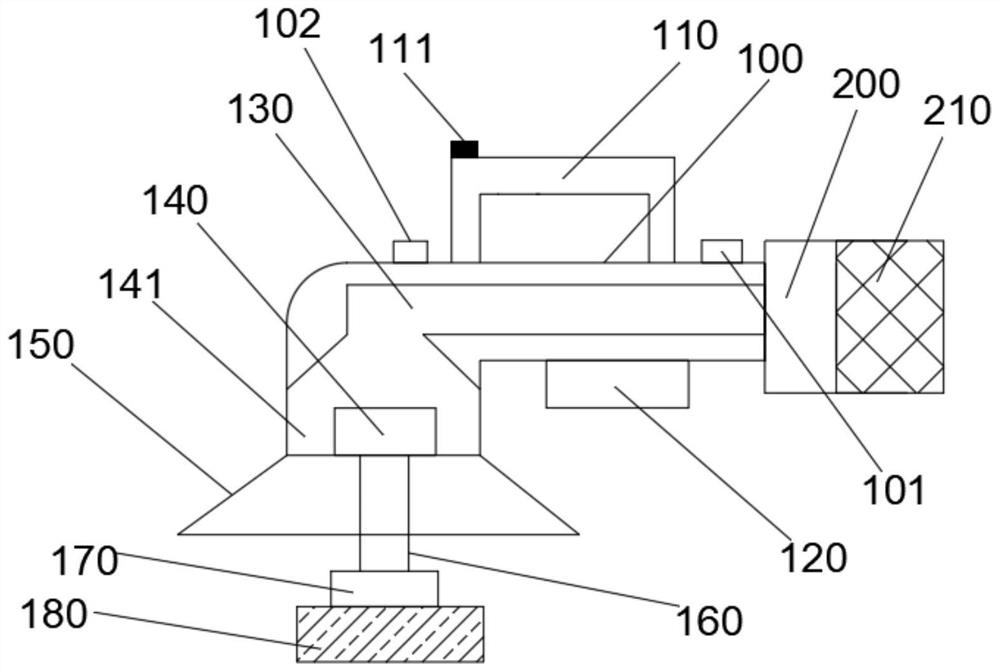

[0026] as attached figure 2 A rapid polishing device for transformer bushings is shown, including an L-shaped device body 100, a handle 110, a two-stage switch 111, a battery compartment 120, an internal air pipe 130, a motor 140, a dust suction channel 141, a dust collection cover 150, Transmission rod 160, polishing rack 170, polishing sheet 180, air pump 200, dust collection box 210; the head of the L-shaped device body 100 is equipped with the dust collection cover 150; the dust collection cover 150 is trumpet-shaped; The L-shaped device body 100 is provided with the handle 110; the handle 110 is provided with a two-stage switch 111; the battery compartment 120 is arranged below the L-shaped device body 100; the L-shaped device The body 100 is provided with the internal air pipe 130; the dust collecting cover 150 is provided with the motor 140; a dust suction channel 141 is left between the motor 140 and the internal air pipe 130; the motor 140 The transmission rod 160 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com