Preparation method of graphene nano-roll

A graphene and nano-roll technology, applied in the field of graphene nano-roll preparation, can solve the problem that the specific surface area of graphene sheets does not have much effect, and achieve the effects of high speed, specific surface area, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of graphene nano volume, comprises the following steps:

[0038] Dispersing the mixed powder of MXene material and graphene in water to form a dispersion liquid, heating, wherein the concentration of the dispersion liquid is 0.1mg / mL~1mg / mL; and

[0039] After the heated dispersion liquid was completely frozen with liquid nitrogen, it was freeze-dried.

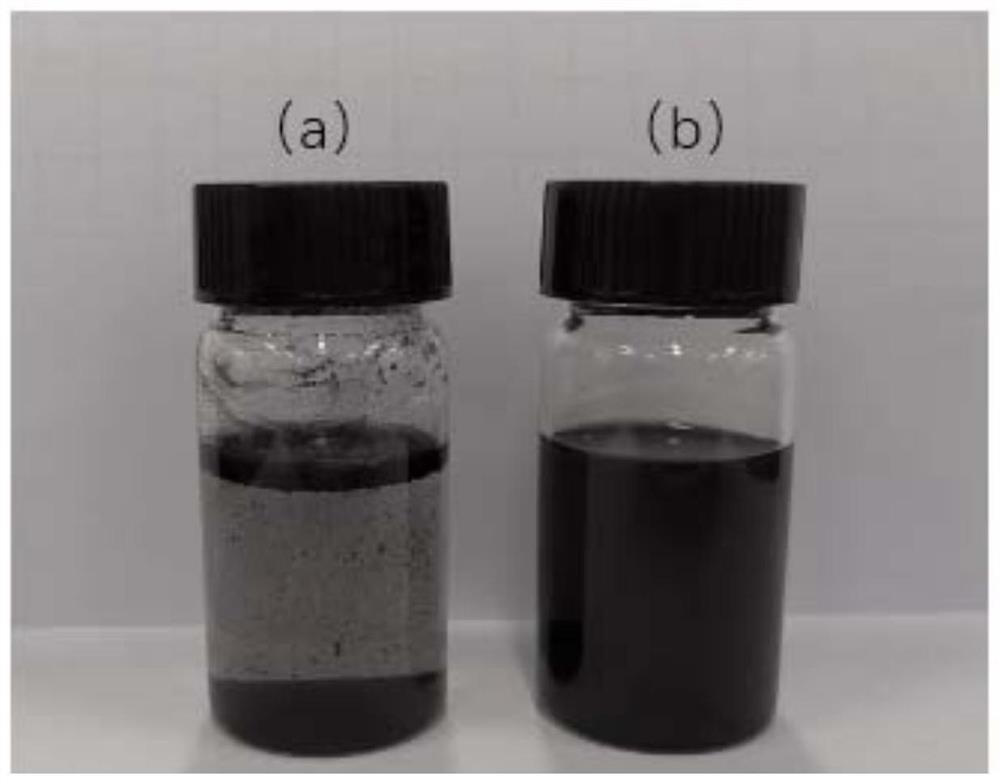

[0040] The present invention utilizes MXene materials and graphene to disperse in water to generate electrostatic repulsion, thereby improving graphene's properties without introducing additives such as modifiers, surfactants, and reducing agents, and without complex reactions with organic polymers. Hydrophilicity makes it stably dispersed in water, and at the same time retains the complete sheet structure of graphene, ensures electrical conductivity, and provides a crucial prerequisite for making graphene rolls. Cooling into rolls by liquid nitrogen, on the basis of ...

Embodiment 1

[0057] The preparation of embodiment 1 graphene nano volume

[0058] 1) Put Ti 2 C 3 T x (T x -OH and -F) mixed with graphene according to the mass ratio of 0.5:50, and dispersed in deionized water after ball milling at 400rpm for 4h, to obtain a dispersion with a concentration of 0.1mg / mL;

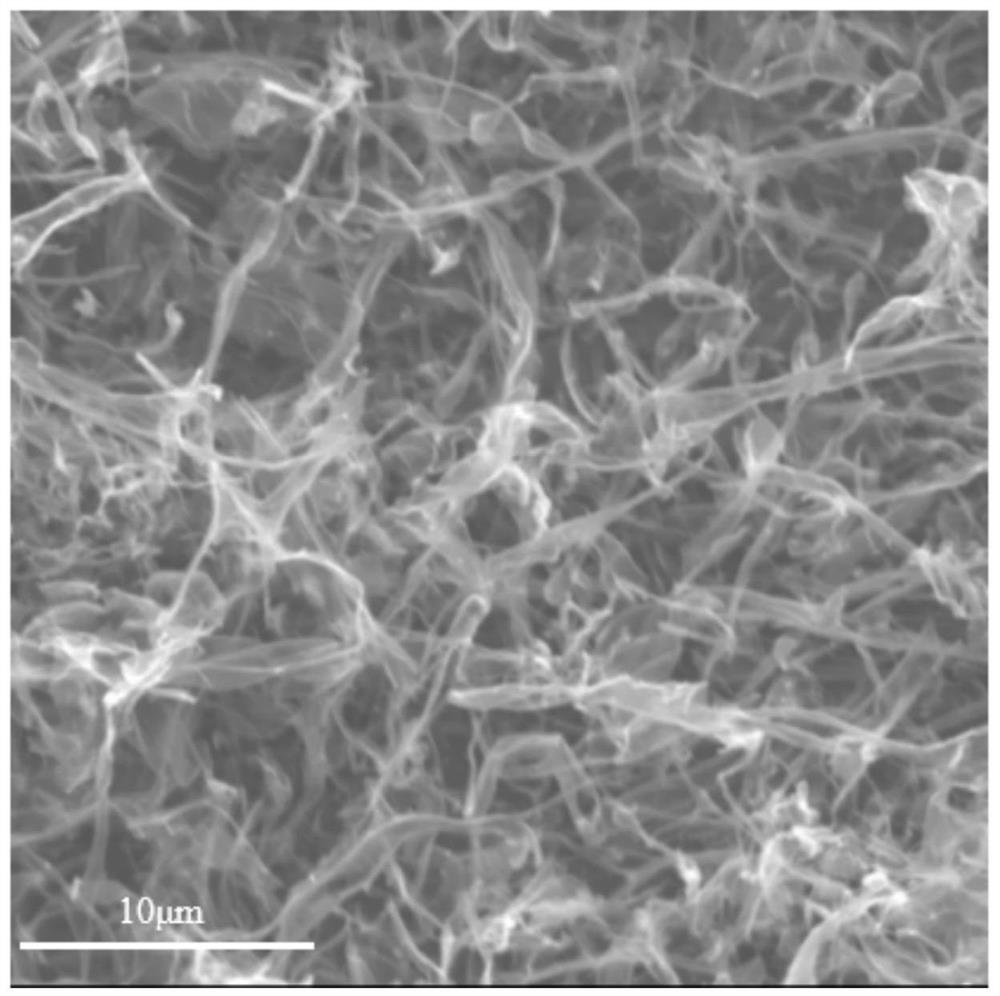

[0059] 2) Stir and heat the dispersion to 60°C, then quickly pour liquid nitrogen into the dispersion, pre-cool at -30°C for 6 hours, and freeze-dry at -50°C for 24 hours to obtain graphene nanoscrolls. The SEM test results of graphene nanovolumes are as follows: figure 1 shown. Depend on figure 1 It can be seen that the number of graphene nanorolls prepared in this embodiment is large, and the rollability is good. After the rolls, the contact points between the sheets are small, and the stacking of the sheets is reduced, so that the specific surface area is larger. The graphene modified by the MXene material has good hydrophilicity, so that the dispersion liquid can exist stably, ...

Embodiment 2

[0062] The preparation of embodiment 2 graphene nano volumes

[0063] The preparation method of this embodiment 2 is basically the same as that of embodiment 1, the difference is that: Ti 2 C 3 T x The mass ratio to graphene is 0.8:50. The specific steps are described as follows:

[0064] 1) Put Ti 2 C 3 T x (T x -OH and -F) mixed with graphene according to the mass ratio of 0.8:50, and dispersed in deionized water after ball milling at 400rpm for 4h, to obtain a dispersion with a concentration of 0.1mg / mL;

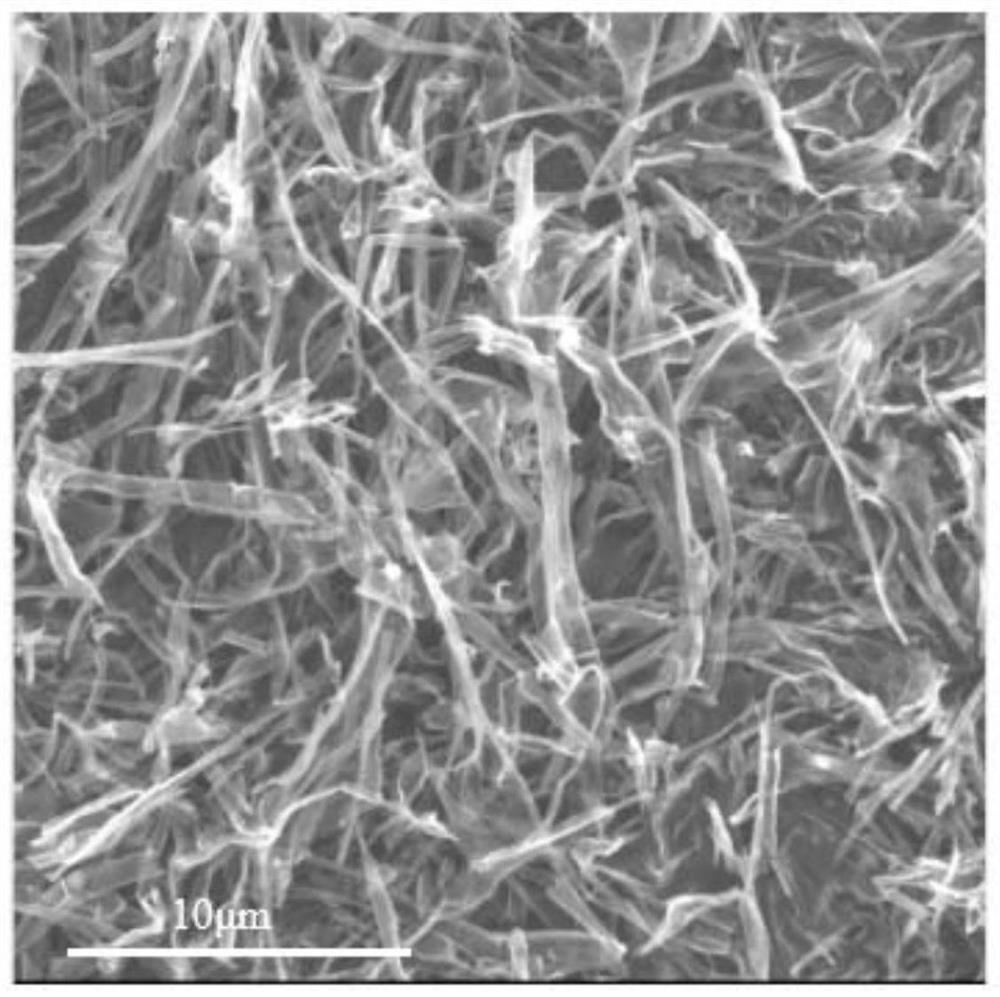

[0065] 2) Stir and heat the dispersion to 60°C, then quickly pour liquid nitrogen into the dispersion, pre-cool at -30°C for 6 hours, and freeze-dry at -50°C for 24 hours to obtain graphene nanoscrolls. The SEM test results of graphene nanovolumes are as follows: image 3 shown. Depend on image 3 It can be seen that the number of graphene nanorolls prepared in this embodiment is large, and the rollability is good. After the rolls, the contact points between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com