Heating device of anaerobic biogas digester and use method of heating device

A biogas digester and biogas technology, which is applied to exhaust devices, mufflers, anaerobic digestion treatment, etc., can solve problems such as increased energy consumption, poor anaerobic digestion effect, and unsatisfactory biogas production effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

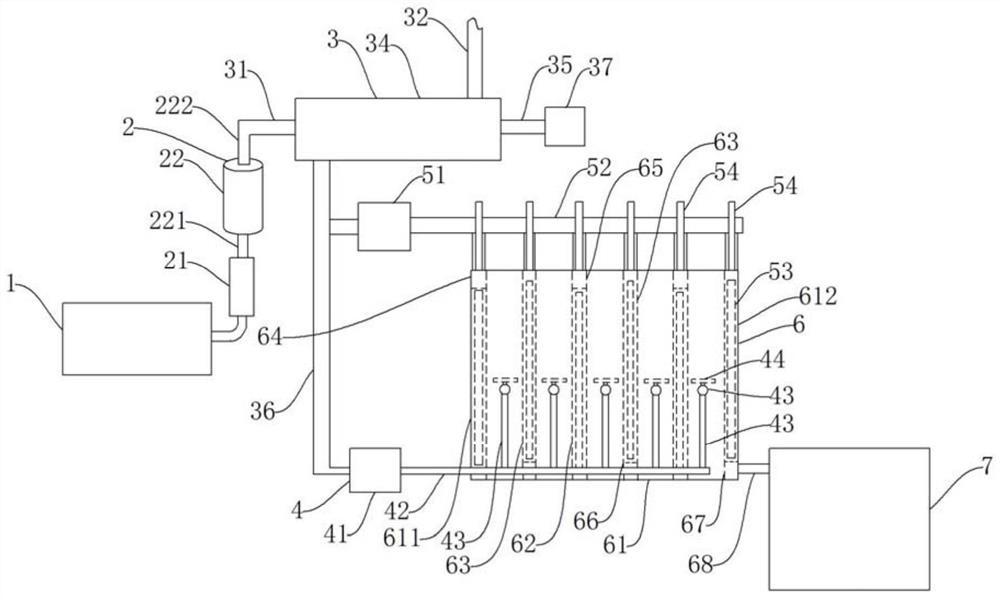

[0044] refer to Figure 1 to Figure 9 , the invention provides a method for using a heating device of an anaerobic digester, comprising the following steps:

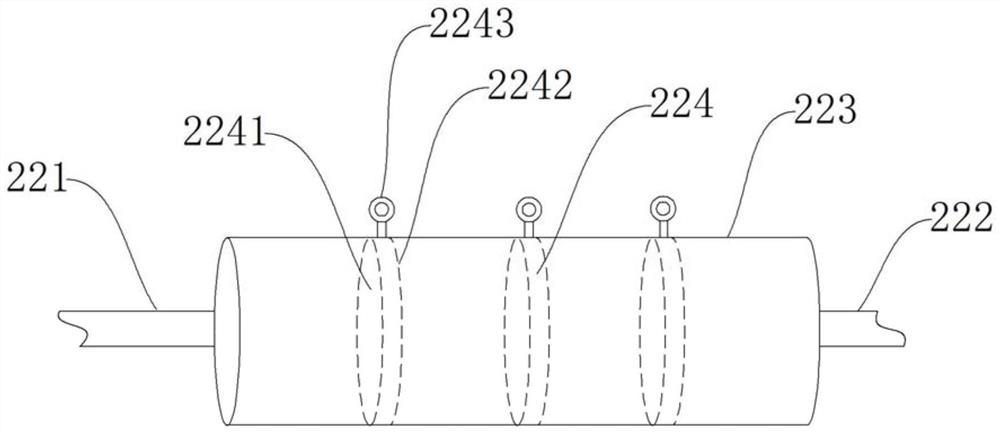

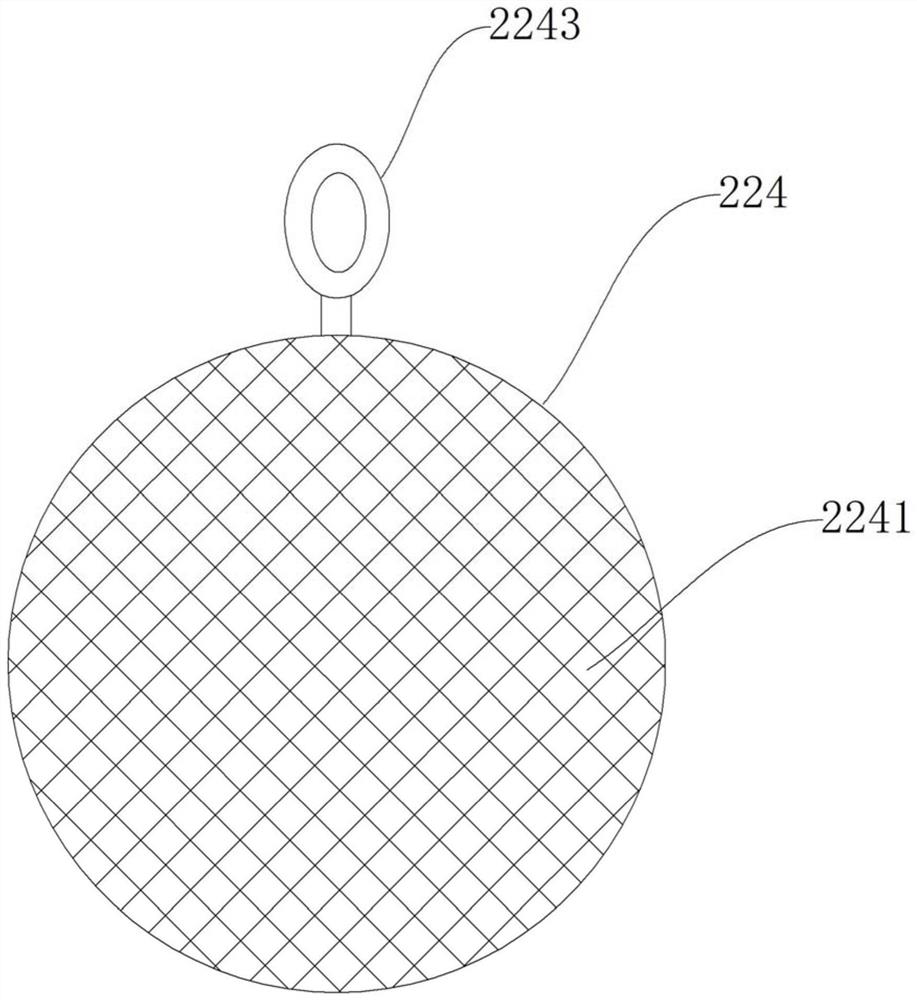

[0045] In step a, the flue gas generated by the biogas generating set 1 passes through the exhaust pipe 21 and the first flue gas inlet pipe 221 in turn, and enters the purification box 223, and the flue gas is filtered by the double-layer filter plate 224 in turn, and the dust in the flue gas Filtered by the high temperature resistant filter screen 2241 and high temperature resistant filter cloth 2242, deposited in the double-layer filter plate 224, the purified flue gas is discharged from the first flue gas outlet pipe 222, and enters the heat exchange system 3;

[0046] Step b, the purified flue gas enters the heat exchange box 34 through the second flue gas inlet pipe 31 and the flue gas inlet, and the slow speed fan 37 blows the outside air into the air coil 33 through the air inlet pipe 35, and the air flows along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com