High-strength compound fertilizer and preparation method thereof

A compound fertilizer and high-strength technology, which is applied in the direction of urea compound fertilizer, potash fertilizer, nitrogen fertilizer, etc., can solve problems such as uneven packaging, difficulty in controlling production costs, and material adhesion, so as to reduce fertilizer caking rate, weaken hygroscopicity, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

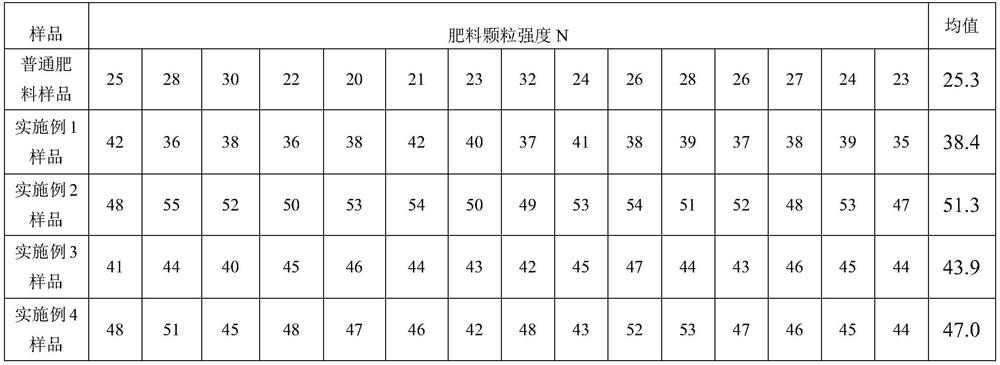

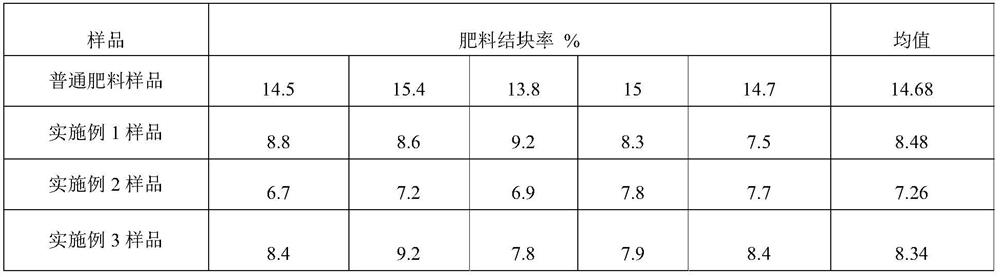

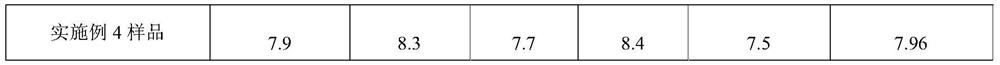

Embodiment 1

[0043] (1) Add 90 kg of urea, 5 kg 60% phosphate, add 0.1 kg of sodium hydroxide, and the reaction temperature is 105 to 115 ° C, forming urea melt low temperature melt solution.

[0044] (2) In the reactor containing 37% formaldehyde solution, 40% concentration of sulfuric acid solution was added, and the solution pH was adjusted to 5 to form an acidic formaldehyde solution.

[0045] (3) In the granulation roller, 5kg of the urea cryogenic melt solution is sprayed into the granulator inner composite fertilizer, and 1 kg of acidic formaldehyde solution is injected, and the reaction is 10 min, and the surface of the fertilizer particle is low. Reactive condensation curing with acidic formaldehyde solution, carry out production of 15-15-15 plain ureadehyde high strength composite fertilizer.

[0046] (4) After the reaction is completed, after drying, cooling, and sieving treatment, the urea is prepared high strength fertilizer.

Embodiment 2

[0048] (1) Add 93 kg of urea, 7 kg 60% phosphate, adding an ammonium of the reaction to the reactor, and 0.3 kg of sodium hydroxide is added, and the reaction temperature is 105 to 115 ° C, and the urea melt is formed low temperature melt solution.

[0049] (2) In the reactor containing 37% formaldehyde solution, 40% concentration of sulfuric acid solution was added, and the solution pH was adjusted to 5 to form an acidic formaldehyde solution.

[0050] (3) In the roller, 10 kg of the urea cryogenic melt solution is sprayed into the combined fertilizer of the granulator, and 1 kg of acidic formaldehyde solution is injected, and the reaction is 10 min, and the surface of the fertilizer particles is low-temperature melt and acidic. The reaction condensation curing of formaldehyde solution is carried out, carry out 15-15-15 plans of ureahandhyde high strength composite fertilizer.

Embodiment 3

[0052] (1) 95 kg of urea, 10 kg 60% phosphate was added to the reactor, and 0.7 kg of sodium hydroxide was added, and the reaction temperature 105 to 115 ° C was added to form urea melt cryogenic molten melt solution.

[0053] (2) In the reactor containing 37% formaldehyde solution, 40% concentration of sulfuric acid solution was added, and the solution pH was adjusted to 5 to form an acidic formaldehyde solution.

[0054] (3) In the roller, 6kg of the above urea cryogenic melt solution is sprayed into the granulator inner composite fertilizer, and 1 kg of acidic formaldehyde solution is injected, and the reaction is 10 min, and the surface of the fertilizer particles is low-temperature melt and acidic. The reaction condensation curing of formaldehyde solution is carried out, carry out 15-15-15 plans of ureahandhyde high strength composite fertilizer.

[0055] (4) After the reaction is completed, after drying, cooling, and sieving treatment, the urea is prepared high strength fert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com