System and method for removing floccules in concentrated formic acid product

A flocculent, concentrated formic acid technology, applied in the field of formic acid preparation, can solve the problems of poor removal effect, unfavorable concentrated formic acid product sales, affecting the appearance of concentrated formic acid products, etc., and achieves the effect of simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

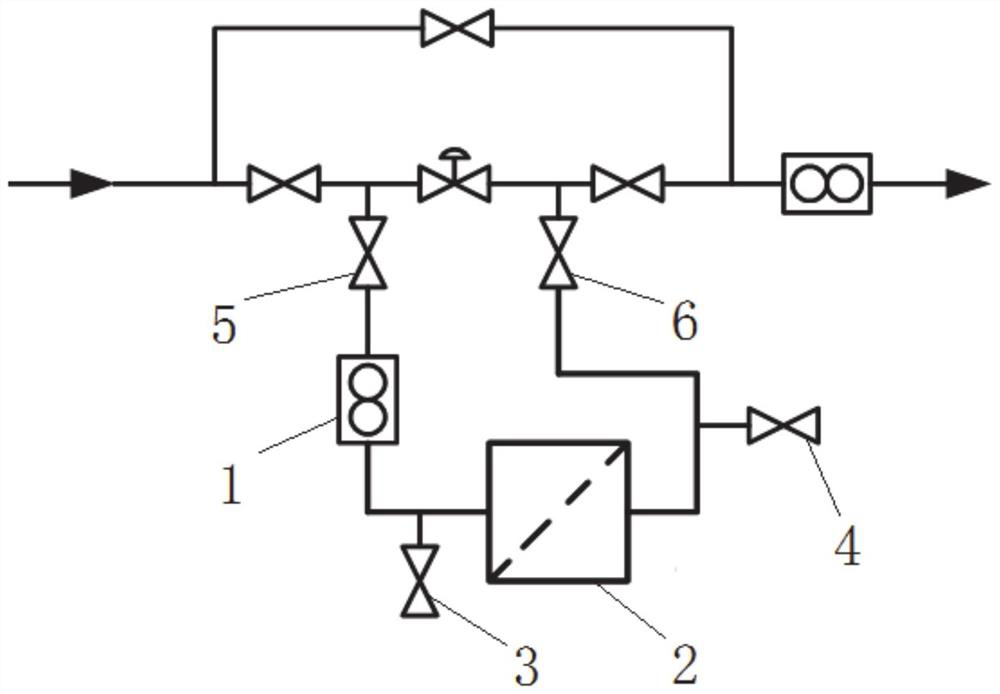

Image

Examples

Embodiment 1

[0041] Select 100ml of PAM resin (polyacrylamide ion exchange resin), fill it into a glass column with pure water, and perform acid washing (5% HCl, treatment for 2h), alkali washing (5% NaOH, treatment for 2h) and water washing (de-salted water washing) Neutral); then replace the water in it with 99% formic acid solution, use a peristaltic pump to transport 99% formic acid flow reaction substance, control the flow rate at 10ml / min, detect the change of the main metal ion content in the solution before and after the treatment: the zinc element is 0.0282 The ppm dropped to 0.0056ppm, the iron element dropped from 0.0778ppm to 0.0212ppm, and the titanium element dropped from 0.0447ppm to 0.0061ppm. The treated 99% formic acid is colorless and transparent.

Embodiment 2

[0046] Choose 100ml KIP242 type purification resin (cation exchange resin), purchased from Hebei Kairui Environmental Protection Company, use pure water to fill in the glass column, first use formic acid solution to carry out pretreatment to this substance (the treatment amount is 1.5-2 of the volume of reaction substance) times), using a peristaltic pump to transport 99% formic acid circulation reaction substances, the flow rate was adjusted to 5ml / min, 10ml / min and 20ml / min respectively, after running for 24 hours, the zinc content in the solution dropped from 0.1505ppm to 0.0585ppm, 0.0294ppm respectively and 0.0295ppm, iron element content decreased from 0.5271ppm to 0.1195ppm, 0.0214ppm and 0.0287ppm, titanium element content decreased from 0.5971ppm to 0.0062ppm, 0.0021ppm and 0.0030ppm respectively.

[0047] After experiments, it was found that when the flow rate is small, the treatment effect is worse. The reason is analyzed: when the flow rate of formic acid is small, ...

Embodiment 3

[0050] Select 0.1m 3KIP242 type purification resin (cation exchange resin), purchased from Hebei Kairui Environmental Protection Company, filled into the reactor with pure water, replaced the water in the reaction substance with 99% formic acid, used pH test paper to detect 2-3 and replaced when the solution was clear Completed; adjust the flow meter to convey the material, and set the flow rate to 0.1m 3 / h, after running for about 140h, the content of main metal elements such as zinc, iron and titanium before and after solution treatment is basically unchanged (or even slightly increased), and the reaction substance is invalid. A total of 44.44m 3 Formic acid solution; after treatment with nitric acid, it is put into operation, and the flow rate is set to 0.1m 3 / h, loses its effect after 80 days of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com