Supercritical carbon dioxide assisted periodic devolatilization process and device

A carbon dioxide and supercritical technology, which is applied in the production of bulk chemicals, chemical instruments and methods, and separation methods, can solve the problems of high-efficiency devolatilization and discharge in the vacuum devolatilization process, and promote rapid degassing and degassing volatilization, improve devolatilization efficiency, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

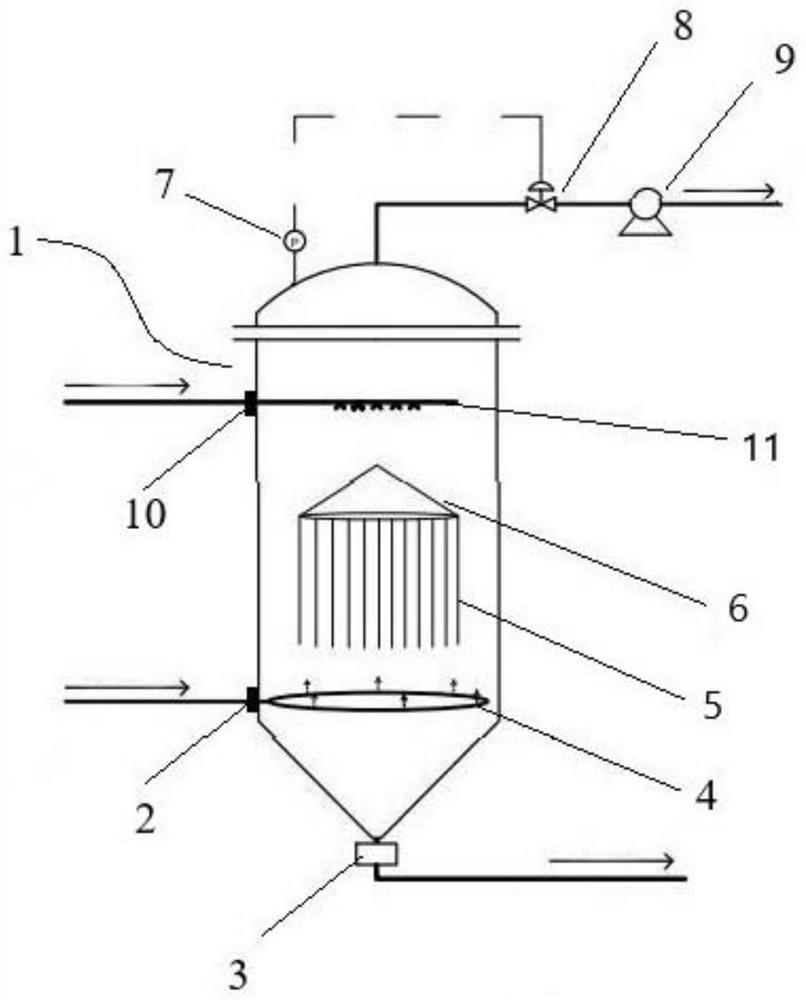

[0046] refer to figure 1 , the present embodiment provides a supercritical carbon dioxide-assisted periodical devolatilization device, comprising a devolatilization tank 1, a pressure sensor 7 and a vacuum pump 9; the top of the devolatilization tank 1 is provided with an exhaust port 11, and the exhaust port 11 is connected to The vacuum pump 9 is connected; the pressure sensor 7 is connected with the devolatilization tank 1 and the vacuum pump 9 respectively; the pressure sensor 7 is connected with the vacuum valve 8 of the vacuum pump 9, and the critical pressure of the pressure sensor 7 is set, and when the pressure in the devolatilization tank 1 reaches the critical pressure, The vacuum valve 8 is opened or closed, and the vacuum pump 9 starts / stops working. Preferably, the outer wall of the devolatilization tank 1 is provided with a heat preservation jacket, and a circulating heat medium / cold medium is arranged in the heat preservation jacket,

[0047] The top of the de...

Embodiment 2

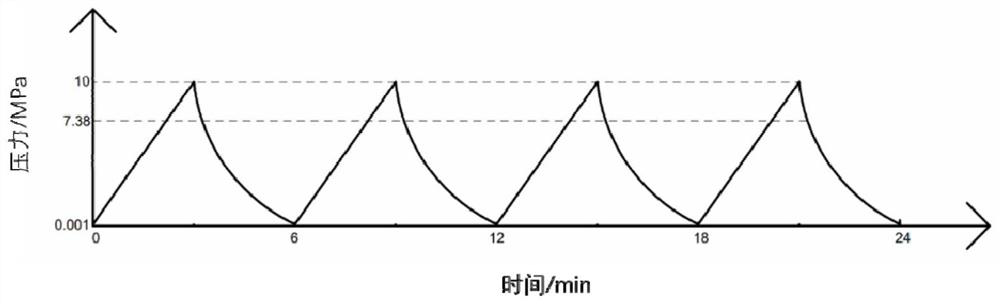

[0067] This embodiment takes high-viscosity polymers as an example, specifically including but not limited to SAN resin, polymethyl methacrylate (PMMA), polyacrylonitrile (PAN), etc. The devolatilization characteristic of high-viscosity polymers is that bubbles Many but not easy to completely remove, this embodiment is a periodic devolatilization process, including multiple pressure cycles, with carbon dioxide as the supercritical medium, the pressure first increases and then decreases during the pressure cycle, so that the carbon dioxide is in a supercritical state Change between gaseous and gaseous states to achieve polymer devolatilization.

[0068] Specifically, this embodiment takes PMMA as an example. The devolatilization process of PMMA in the prior art mostly adopts extruder extruding mode to carry out devolatilization. Chinese invention patent CN113459324A discloses a devolatilization screw extruder device and a method for producing PMMA using the device, which uses ...

Embodiment 3

[0078] This embodiment takes polystyrene (PS) as an example to further illustrate the technical solution of the present invention.

[0079] Chinese invention patent CN10220109A discloses a supercritical fluid devolatilization method for polystyrene, which includes using carbon dioxide as a supercritical medium to realize the devolatilization process of polystyrene, which can reduce the residual monomer in the polymer to 1ppm the following. However, the devolatilization process takes a long time and can be completed in at least 6 hours, and the devolatilization efficiency is low. And it uses polystyrene resin particles as raw material, intermittent fixed bed for devolatilization, that is, the product is devolatilized after the production is completed, the effect is better for polystyrene resin particles with small particle size, and for the requirements particle size, this process cannot complete the devolatilization process. Therefore, the practical significance is limited. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com