Thermochromic radiation refrigeration coating, thermochromic radiation refrigeration film and preparation method thereof

A technology of thermochromism and radiation cooling, applied in heat-sensitive coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as increasing heating energy consumption, achieve the effect of promoting radiation cooling, enhance solar radiation reflection, and maintain comfort The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 This example provides a thermochromic radiation cooling coating, a thermochromic radiation cooling film and a preparation method thereof.

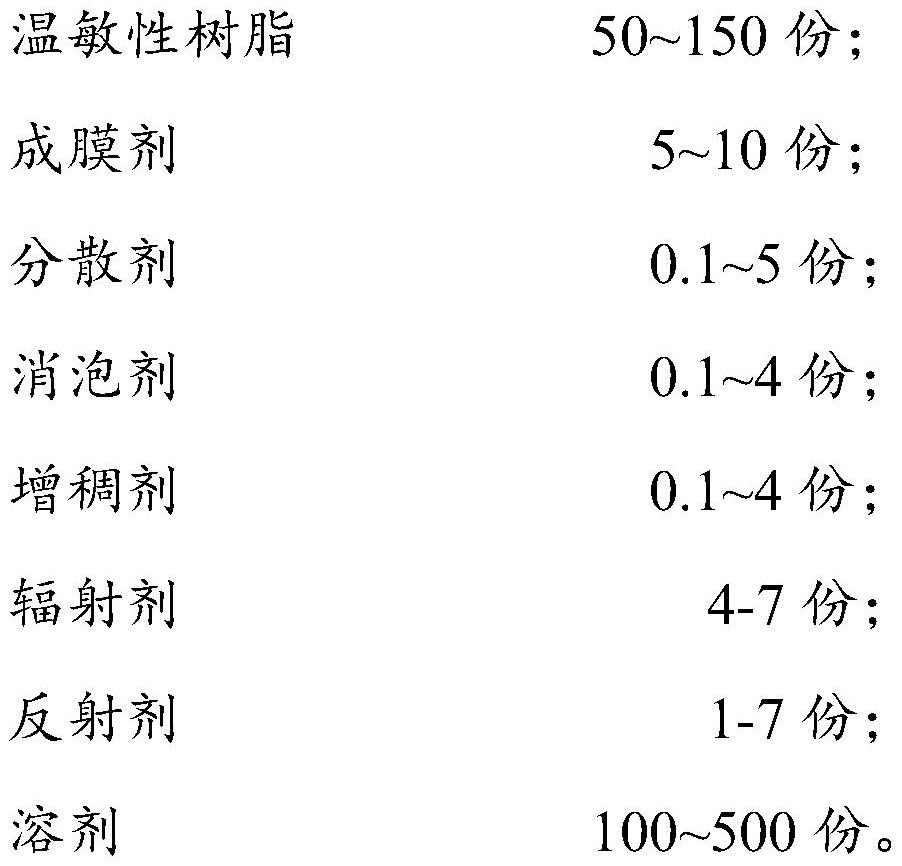

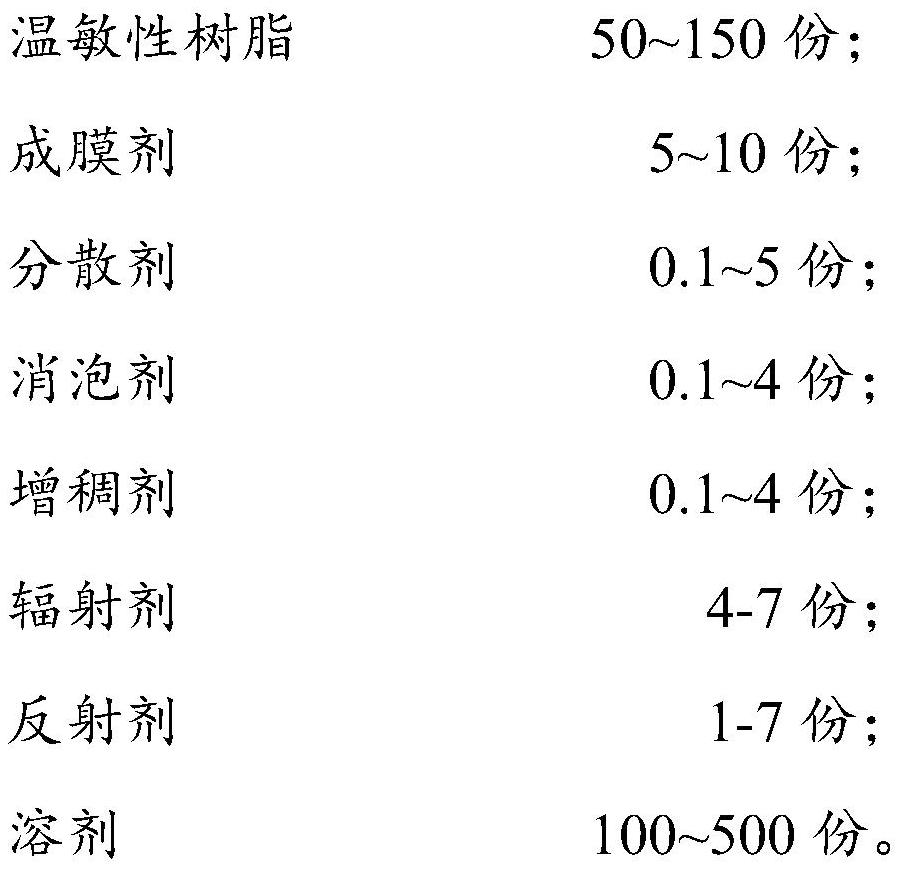

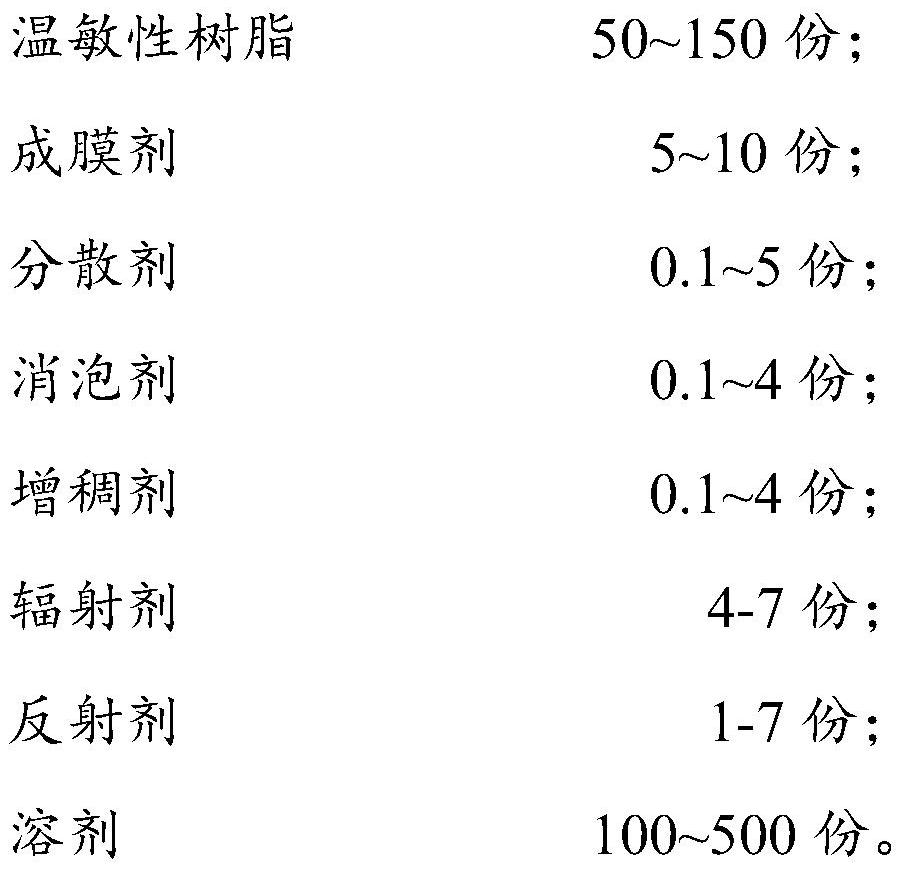

[0041] 1. The raw materials for the preparation of thermochromic radiation refrigeration coatings include the following components in parts by weight:

[0042]

[0043]

[0044] 2. A thermochromic radiation refrigeration film, its preparation method is as follows:

[0045] Mix and stir the above-mentioned temperature-sensitive resin, film-forming agent, dispersant, defoamer, thickener, radiation agent, reflector, and solvent for 90 minutes to form a thermochromic radiation refrigeration coating, and coat the thermochromic The radiative cooling coating was prepared with a film thickness of 400 μm.

[0046] 3. The thermochromic temperature of the film prepared above was measured by an ultraviolet spectrophotometer to be 37.4°C.

[0047]

[0048] After the film of the invention changes color repeatedly for 1000 tim...

Embodiment 2

[0049] Example 2 This example provides a thermochromic radiation refrigeration coating, a thermochromic radiation refrigeration film and a preparation method thereof, which are basically the same as in Example 1, except that some of the preparation raw materials are different, and the specific differences are as follows: The molecular weight of N-isopropylacrylamide is 10 4 g·mol -1 .

[0050] The thermochromic temperature of the film prepared above was measured by an ultraviolet spectrophotometer to be 34.8°C.

[0051]

[0052]

[0053] After the film of the invention changes color repeatedly for 1000 times, its color changing performance and radiation cooling performance are still stable.

Embodiment 3

[0054] Example 3 This example provides a thermochromic radiation refrigeration coating, a thermochromic radiation refrigeration film and a preparation method thereof, which are basically the same as in Example 1, except that some of the preparation raw materials are different, and the specific differences are as follows: The molecular weight of N-isopropylacrylamide is 10 5 g·mol -1 .

[0055] The thermochromic temperature of the film prepared above was measured by an ultraviolet spectrophotometer to be 33.6°C.

[0056]

[0057] After the film of the invention changes color repeatedly for 1000 times, its color changing performance and radiation cooling performance are still stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com