High-activity metal smoke dust treatment system

A treatment system and high-activity technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of metal dust easy to adhere, pollute, damage equipment, etc., to ensure the continuity of processing and avoid escape The effect of polluting the environment and avoiding unnecessary impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

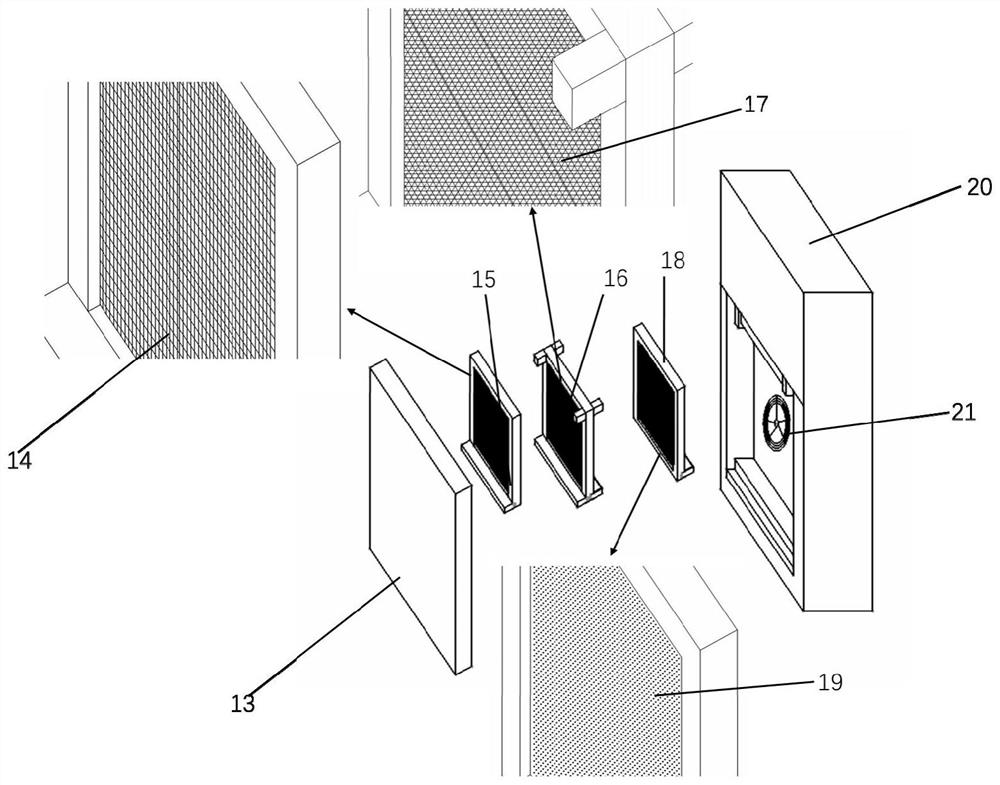

[0027] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

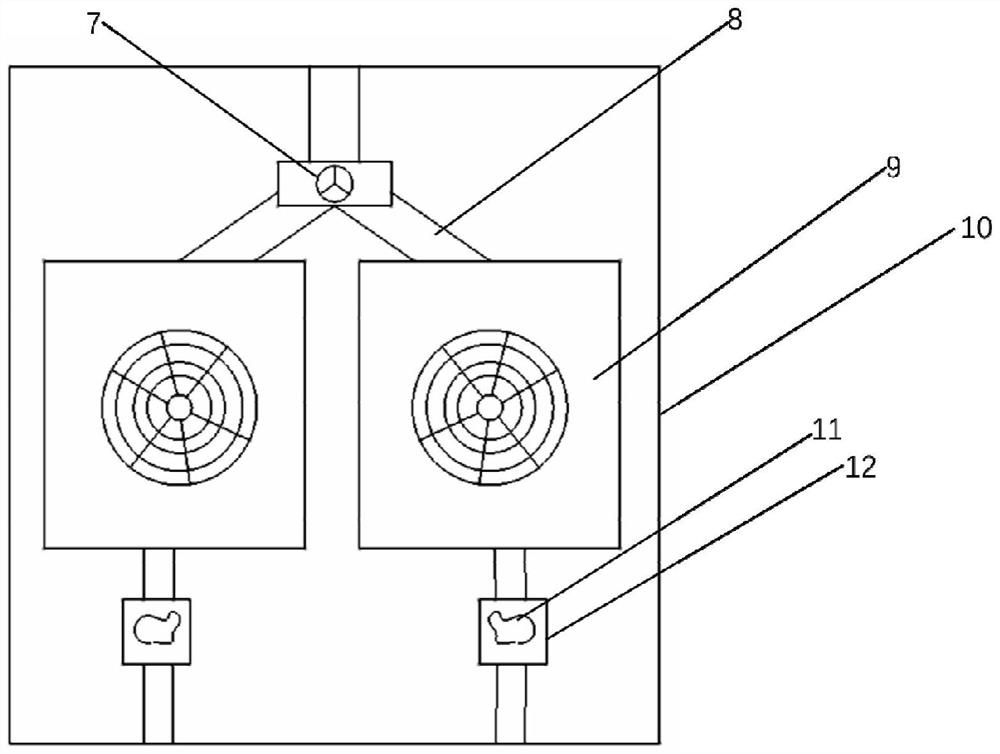

[0028] The high-activity metal dust treatment system in the present invention mainly includes a dust collector, two filter pipelines and pipeline switching components.

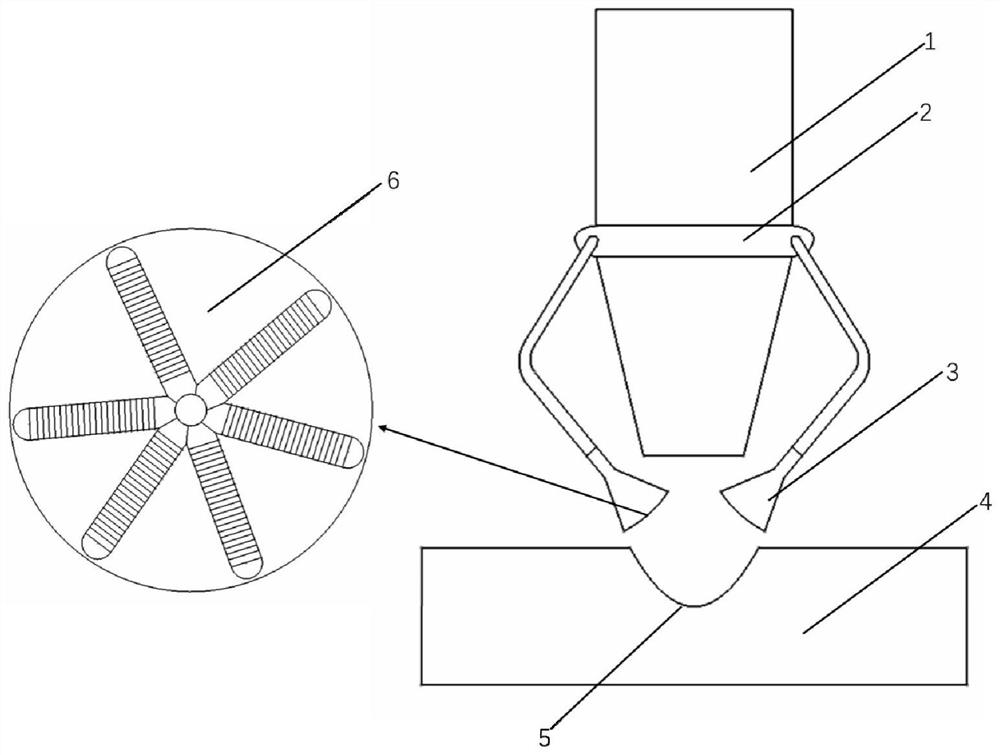

[0029] Specifically, as figure 1 As shown, the soot collector includes a pair of funnel-shaped soot collecting heads 3, the material of which can be selected from copper, steel, WC, etc., and the funnel-shaped soot collecting heads 3 are symmetrically arranged on both sides below the laser head 1 and located on the substrate 4 The upper sides of the melting pool 5 are fixed on the flange 2 of the laser head 1 through the smoke collection pipeline, and the smoke collection pipeline is connected with the two filter pipelines respectively; the funnel of the funnel-shaped smoke collection head is set There is a metal mesh cover 6, which ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com