A kind of ultrasonic plunging cutting tool

A technology for processing cutting tools and ultrasonics, which is applied in the direction of planer/slotting cutting tools, manufacturing tools, metal processing, etc., can solve the problems of large cutting force, increased manufacturing cost of honeycomb core material, and lack of chip removal function, etc., to achieve guaranteed The effect of processing quality and processing accuracy, suppressing crush deformation damage, and ensuring processing continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

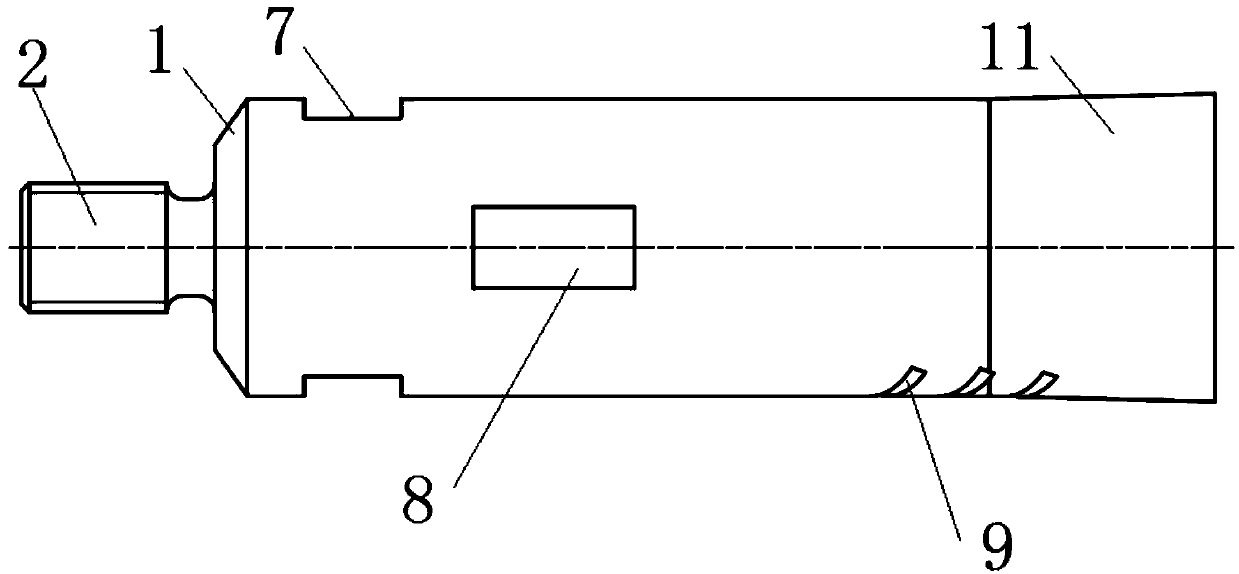

[0035] Such as figure 1 and figure 2 As shown, an ultrasonic plunging cutting tool includes a tool body;

[0036] One end of the tool body has a positioning surface 1, on which a threaded segment 2 connected to the ultrasonic horn is provided, and the other end of the tool body has a groove, and the groove includes a tapered groove bottom 3. A cylindrical hole 4 and a frustum-shaped hole 5 located at the notch of the groove. An arc transition hole 6 is provided between the conical groove bottom 3 and the cylindrical hole 4. The frustum-shaped hole 5 The small end communicates with the cylindrical hole 4;

[0037] The frustum-shaped hole 5 and the outer wall 11 of the tool body away from the end of the positioning surface form a trumpet-shaped cutting edge. The outer wall 11 of the tool body away from the end of the positioning surface is in the shape of a truncated cone. The small end of the outer wall 11 at one end of the positioning surface is located between the two end...

Embodiment 2

[0050] like image 3 As shown, an ultrasonic plunge cutting tool is distinguished from the ultrasonic plunge cutting tool described in Embodiment 1 in that the positioning surface 1 is a stepped surface.

Embodiment 3

[0052] like Figure 4 As shown, an ultrasonic plunge cutting tool is distinguished from the ultrasonic plunge cutting tool described in Embodiment 1 in that the ultrasonic plunge cutting tool has no flutes.

[0053] This embodiment is used for a low-hardness honeycomb core. Due to the low hardness of the low-hardness honeycomb core, the processing deformation is relatively large, and the friction between the inner wall of the groove and the chips of the honeycomb core is small, and the effect of ultrasonic vibration and ultrasonic wear reduction After a cutting is completed, the chip core will be separated from the groove, so as to realize automatic chip removal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com