Preparation method of lithium manganese iron phosphate

A technology of lithium manganese iron phosphate and iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as poor conductivity, difficult preparation, and limited improvement range, so as to improve conductivity and improve electrical conductivity. Chemical properties, effect of reducing local concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

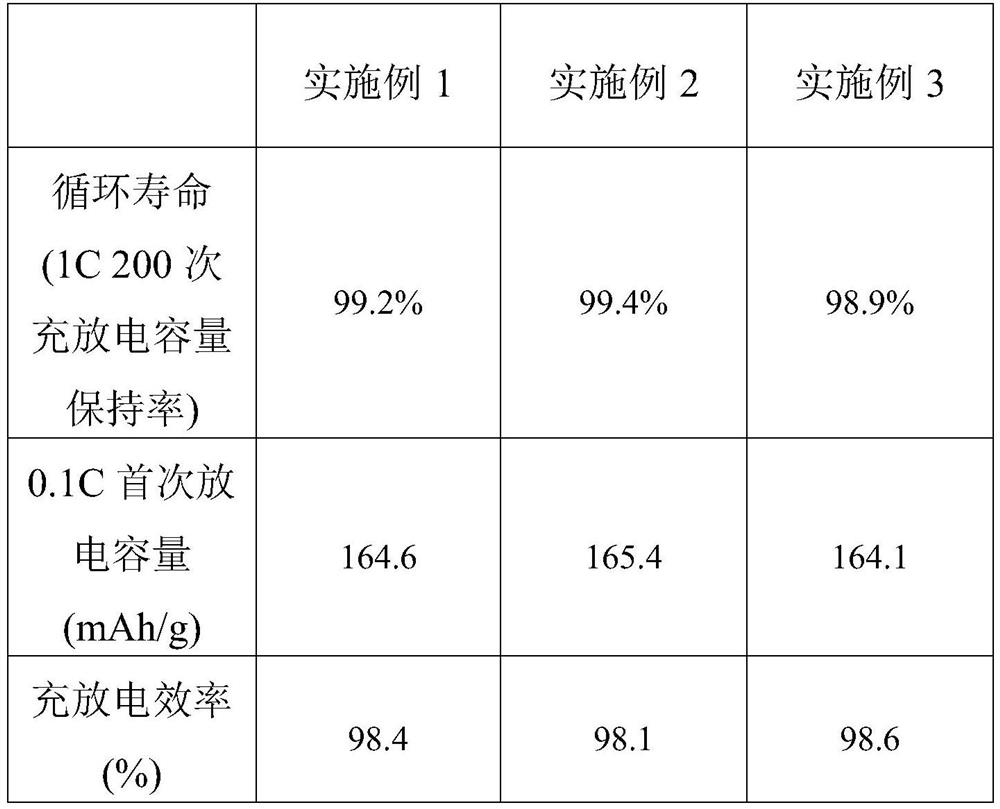

Embodiment 1

[0034] A kind of preparation method of lithium manganese iron phosphate of the present invention comprises the following steps:

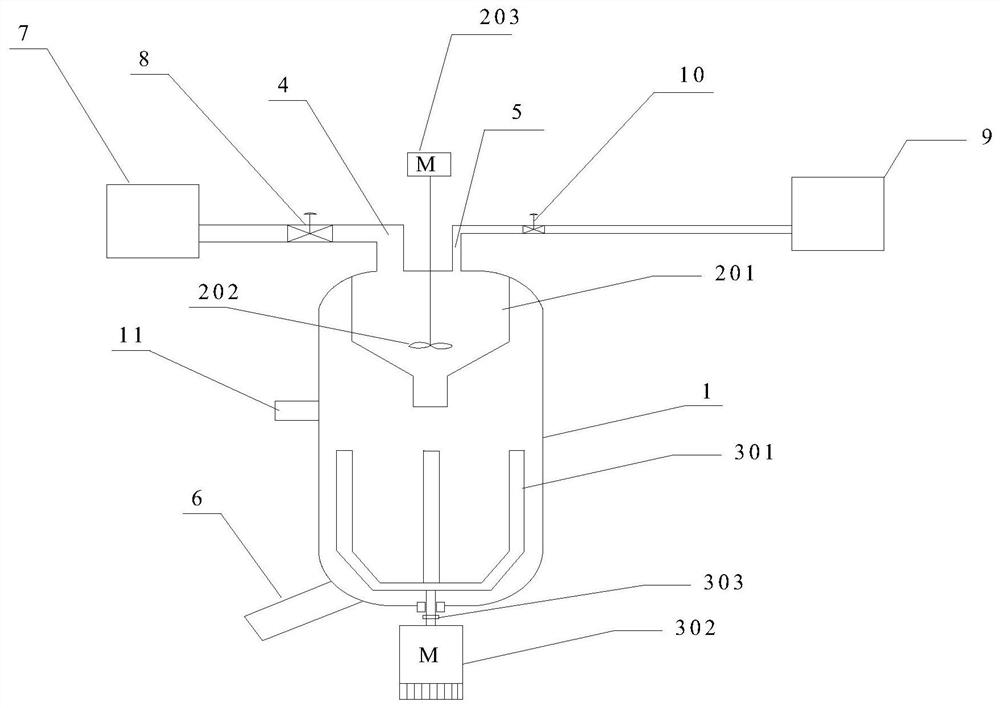

[0035] (1) At normal temperature, ferrous sulfate solution and phosphoric acid are injected into the premixing unit of the reactor in a continuous parallel flow and top feeding mode to obtain premixed raw materials;

[0036] (2) The pre-mixed raw materials enter the bottom of the reactor, and hydrogen peroxide is injected from the feeding port in the middle of the side of the reactor, and the molar ratio of ferrous, phosphoric acid and hydrogen peroxide in the reactor is controlled to be 1:1.2:1, and at the bottom of the reactor Carry out precipitation reaction, control the pH value of the reaction process to 1-2, and the reaction temperature is 60°C, react for 1h, then raise the temperature to 90°C, continue to react for 6h, and obtain a mixed slurry;

[0037] (3) filtering the mixed slurry obtained in step (2), and washing the obtained filter resi...

Embodiment 2

[0047] A kind of preparation method of lithium manganese iron phosphate of the present invention comprises the following steps:

[0048] (1) At normal temperature, ferrous sulfate solution and phosphoric acid are injected into the premixing unit of the reactor in a continuous parallel flow and top feeding mode to obtain premixed raw materials;

[0049] (2) The premixed raw materials enter the bottom of the reactor, and hydrogen peroxide is injected from the feeding port in the middle of the side of the reactor body, and the molar ratio of ferrous, phosphoric acid and hydrogen peroxide in the reactor is controlled to be 1:1.1:0.8, and at the bottom of the reactor Carry out precipitation reaction, control the pH value of the reaction process to be 1-2, and the reaction temperature is 50°C, react for 1h, then raise the temperature to 95°C, continue to react for 4h, and obtain a mixed slurry;

[0050] (3) filtering the mixed slurry obtained in step (2), and washing the obtained fi...

Embodiment 3

[0053] A kind of preparation method of lithium manganese iron phosphate of the present invention comprises the following steps:

[0054] (1) At normal temperature, ferrous sulfate solution and phosphoric acid are injected into the premixing unit of the reactor in a continuous parallel flow and top feeding mode to obtain premixed raw materials;

[0055] (2) The premixed raw materials enter the bottom of the reactor, and hydrogen peroxide is injected from the feeding port in the middle of the side of the reactor, and the molar ratio of ferrous, phosphoric acid and hydrogen peroxide in the reactor is controlled to be 1:1.25:0.7. Carry out precipitation reaction, control the pH value of the reaction process to 1-2, and the reaction temperature is 40°C, react for 2h, then raise the temperature to 85°C, continue to react for 8h, and obtain a mixed slurry;

[0056] (3) filtering the mixed slurry obtained in step (2), and washing the obtained filter residue to obtain an iron phosphate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com