Chlorine-free, fluorine-free and alkali-free liquid accelerator as well as preparation method and application thereof

An accelerator, liquid technology, applied in the field of concrete admixtures, which can solve problems such as damage, corrosion and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

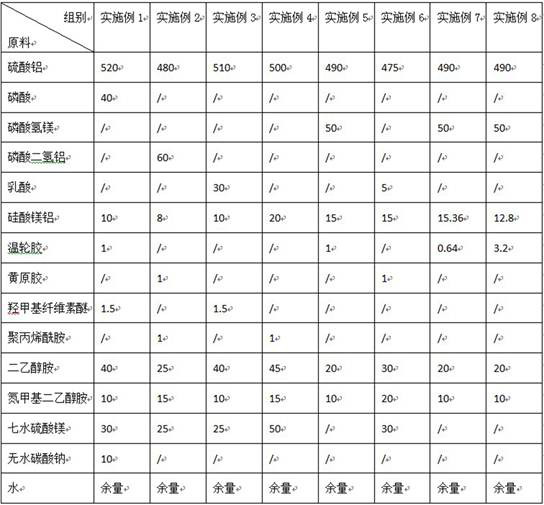

[0056] According to the total weight of the liquid quick-setting agent configured as 1kg, the formula weight (g) of each component of Examples 1-8 is shown in the following table:

[0057] Table 1 Embodiment 1-8 formula details

[0058]

[0059]Note: (1) / means that the raw material is not added; (2) the balance means that the total weight of the system is made up to 1kg with water.

[0060] The liquid accelerator that embodiment 1-8 claims protection adopts following method to prepare

[0061] A preparation method of a chlorine-free, fluorine-free, alkali-free liquid quick-setting agent, comprising the following steps:

[0062] S1: Put the stabilizer into the water according to the proportion of the formula, and stir evenly;

[0063] S2: Add aluminum sulfate according to the recipe amount, continue to stir until uniform, then add the complexing agent in the recipe amount, stir until completely dissolved, and form a uniform liquid;

[0064] S3: Add the early strength ag...

Embodiment 1

[0099] The liquid quick-setting agent obtained in Examples 1-8 and the alkaline quick-setting agent obtained in Comparative Example 1 are similar in shortening the initial setting time of the clean slurry, especially the initial setting of the clear slurry mixed with Example 1 and Example 3 The time is also faster than that of Comparative Example 1; and in terms of the final setting time of the clean slurry, the performance of the liquid accelerators obtained in Examples 1-8 is better than that of the alkaline accelerators obtained in Comparative Example 1.

[0100] As can be seen from Table 2, the liquid quick-setting agent prepared by the present application has a lower alkali content compared with Comparative Example 1, that is to say, it has a better quick-setting effect under the premise of reducing the amount of alkali, so that the concrete can be Gain strength faster, which in turn facilitates shotcrete construction.

[0101] 2.2 Determination of the strength of mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com