Preparation method and application of biodegradable cellulose paper taking lignin as adhesive

A technology for degrading cellulose and cellulose paper, applied in the direction of non-fibrous pulp addition, fiber raw material treatment, inorganic compound addition, etc., can solve problems such as poor water resistance, poor mechanical strength of plastic substitutes, unstable moisture content of cellulose paper, etc. , to achieve excellent wet strength, improved heat resistance and UV resistance, and good UV absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of biodegradable cellulose paper using lignin as binder:

[0041] (1) Cut the cellulose paper into 10×20cm 2 Swell the rectangle in 4% (w / w) sodium hydroxide aqueous solution for 2h, then soak in ethanol / water (1 / 1, v / v) for 30min to remove residual chemical substances, operate as above, use ethanol / water wash five times;

[0042] (2) Put the washed cellulose paper sample into dehydrated alcohol and soak for 30min, remove the water in the cellulose paper sample, and set aside;

[0043] (3) Disperse the alkali lignin in acetone, perform ultrasonic treatment, and then centrifuge the solution at 5000rpm for 10min to obtain a supernatant;

[0044] (4) seal and soak the puffed cellulose paper in 500mL of the above supernatant for 12 hours, evaporate the acetone at room temperature, fully penetrate the lignin solution with alkali lignin, and allow the lignin to cover the cellulose fibers;

[0045] (5) The cellulose-lignin material is then hot-pressed ...

Embodiment 2

[0047] Determination of lignin concentration:

[0048] Adopt the preparation method of above-mentioned embodiment 1, wherein the concentration of lignin in the supernatant obtained in step (3) is respectively set as 0%, 7%, 13%, 26%, 38%, 47%, and step (5) The medium hot pressing temperature was set at 100°C, and the properties of the materials prepared with different concentrations of lignin were tested respectively. The specific results are as follows: Figure 1-7 Shown:

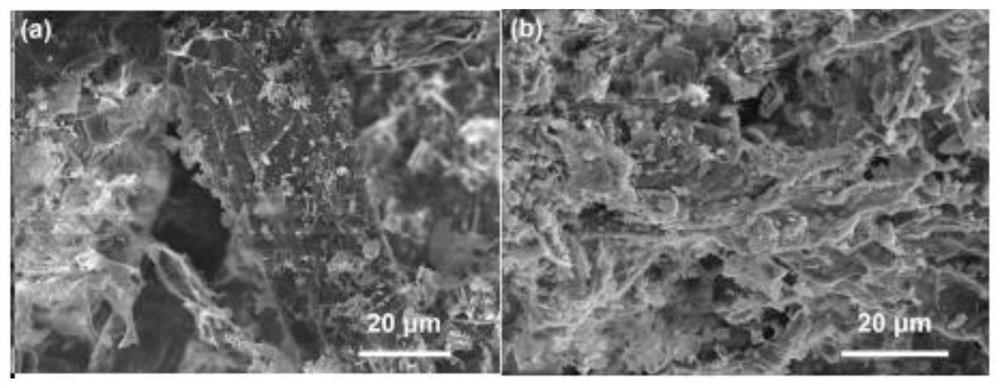

[0049] Mechanical stability test: use Instron3367 material tensile testing machine to test the mechanical properties of lignin-cellulose samples. Cut the size of the tensile sample to 100mm×5mm×0.04mm, clamp both ends of the sample, and -1 The constant test speed is stretched along the length of the sample until it breaks, and the result is the average of the two measurements.

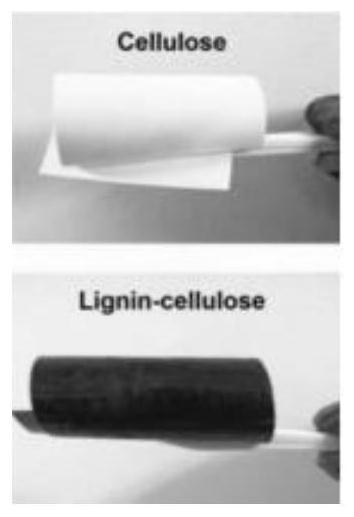

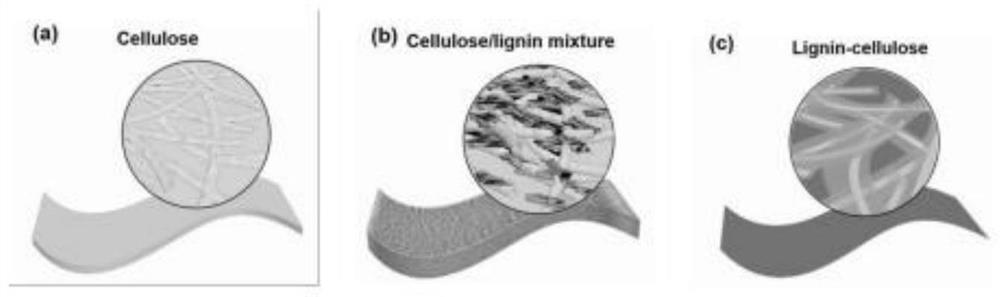

[0050] in figure 1 The ordinary cellulose paper and the lignin-cellulose composite paper with a lignin concentration of 26% i...

Embodiment 3

[0055] Determination of hot pressing temperature:

[0056] The concentration of lignin in the supernatant obtained in the above-mentioned embodiment 1 step (3) is set to 26%, and the hot-pressing temperature is set to 50°C, 100°C, 130°C, 150°C respectively in the step (5), and the remaining steps and implementation The same as Example 1, the mechanical strength of lignin-cellulose is detected under different hot-pressing temperatures, and the specific results are shown in Figure 8 , where it can be known that the mechanical strength is the best when the hot pressing temperature is 100-130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com