Antibacterial degradable functional film forming processing technology and equipment

A film forming and processing technology, which is applied in the field of functional film forming and processing technology and its equipment, can solve the problems of low preparation quality and poor antibacterial performance of decomposable films, and achieve the reduction of cytotoxicity, inhibition of bacterial growth, and preparation process perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

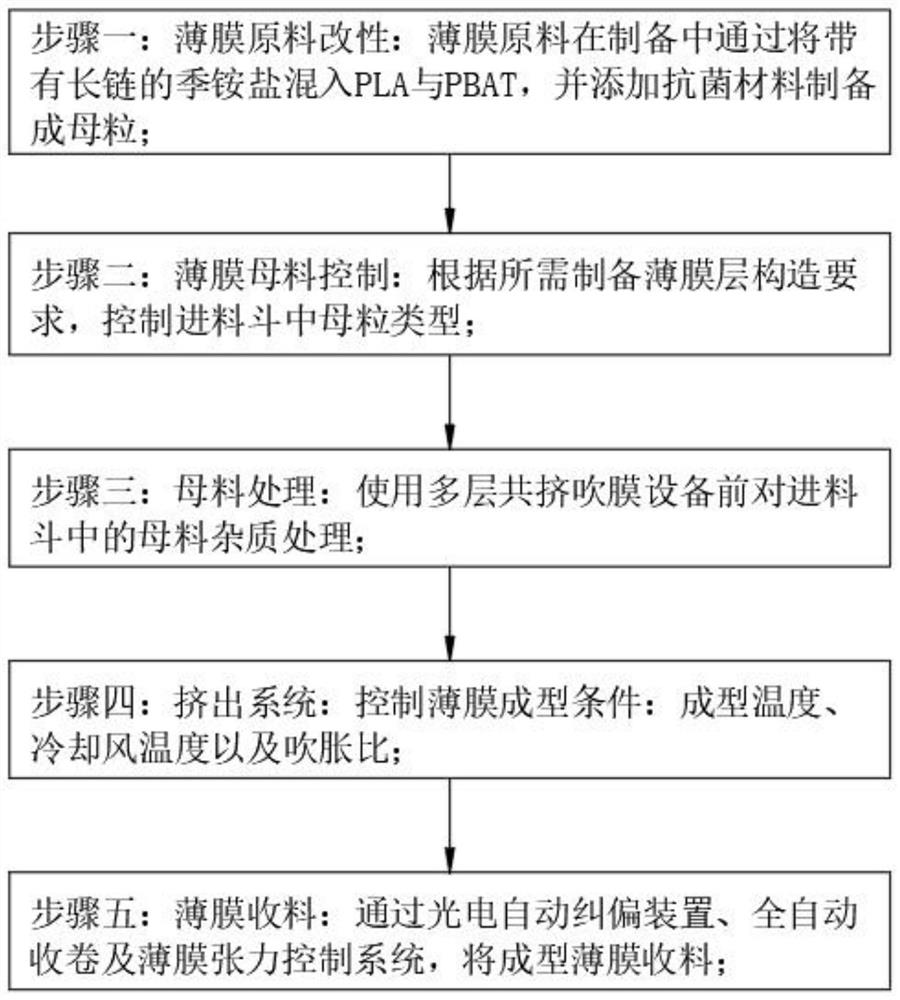

[0028] Such as figure 1 As shown, a kind of antibacterial and degradable functional film molding processing technology that the present invention proposes, processing technology comprises the following steps:

[0029] Step 1: In the preparation of film raw materials, antibacterial masterbatches are prepared by mixing quaternary ammonium salts with long-chain alkyl groups into PLA and PBAT, and adding antibacterial materials; the preparation process of antibacterial masterbatches is: long-chain alkyl quaternary ammonium salts Mixing and extruding with the initiator cerium ammonium nitrate and PBAT in extrusion granulation equipment, the temperature is 70°C, the reaction time is 1.5h, and the content of the cerium ammonium nitrate is 0.8%;

[0030] Step 2: Film masterbatch control: According to the required film layer structure requirements, control the type of masterbatch in the feeding hopper;

[0031] Step 3: Masterbatch treatment: before using the multilayer co-extrusion bl...

Embodiment 2

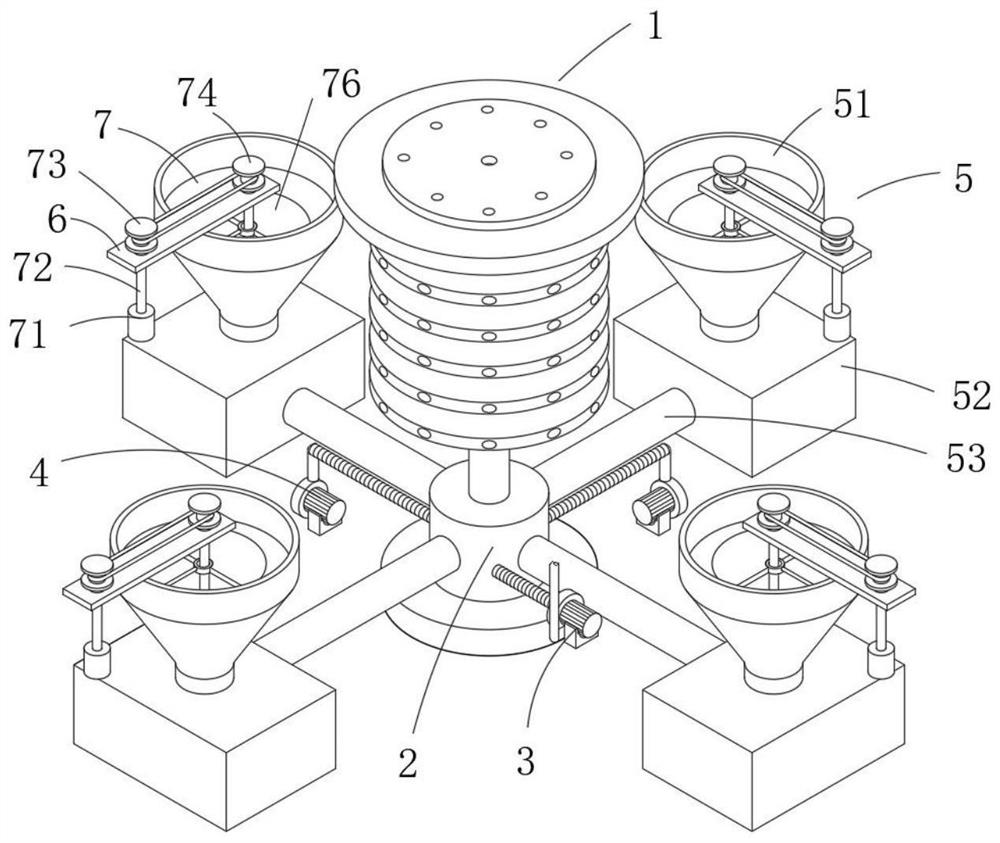

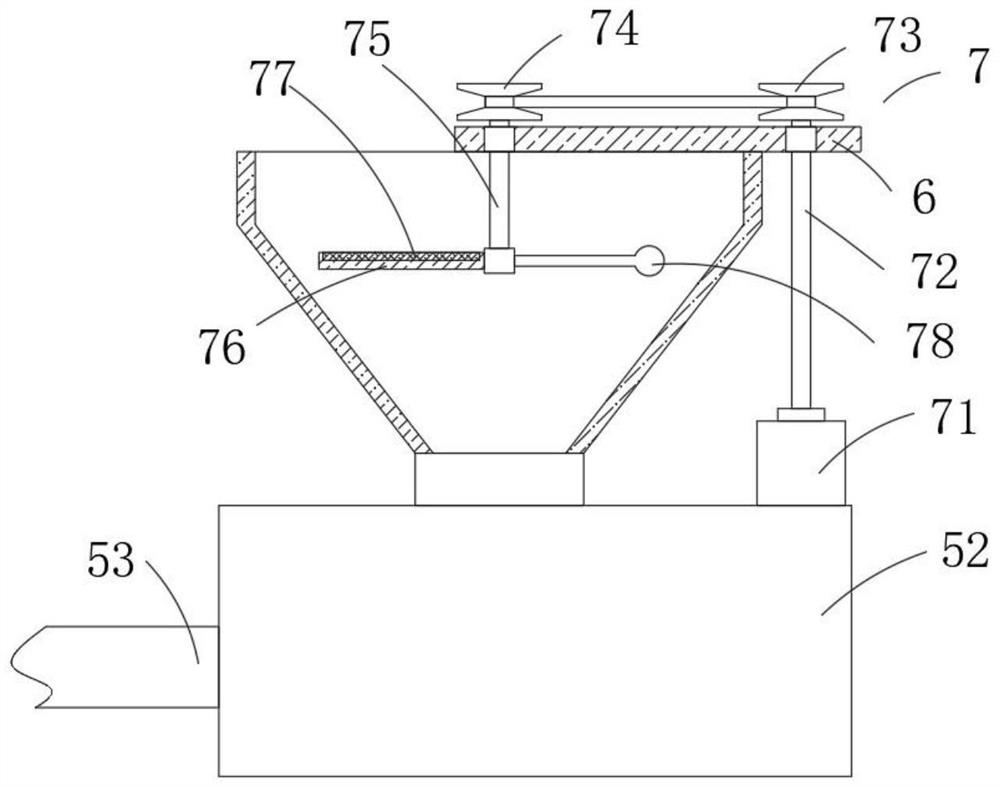

[0035] Such as Figure 2-3As shown, an antibacterial and degradable functional film forming and processing equipment proposed by the present invention, compared with Embodiment 1, the processing equipment of this embodiment includes a die body 1, a base 2 is installed on the bottom of the die body 1, and a base 2 The outer ring is provided with an exhaust fan 3 and a blower 4, and the exhaust fan 3 and the blower 4 are connected with an air duct, and the exhaust fan 3 is also connected with a waste gas exhaust pipe, which is used to discharge the generated waste gas to ensure that the equipment The safety of use, the air guide tube is connected with the base 2, the outer ring of the base 2 is provided with a feeding mechanism 5 along its circumference, there are multiple feeding mechanisms 5, the feeding mechanism 5 includes a feeding hopper 51, An injection molding machine 52 is installed at the bottom of the injection molding machine 52, and a pipe 53 is connected to one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com