Phosphorus-nitrogen synergistic flame retardant compound as well as preparation method and application thereof

A technology of synergistic flame retardant and compound, applied in the field of flame retardant materials, can solve problems such as affecting the mechanical properties of epoxy resin, and achieve the effect of small mechanical properties, solving mechanical properties, and improving flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

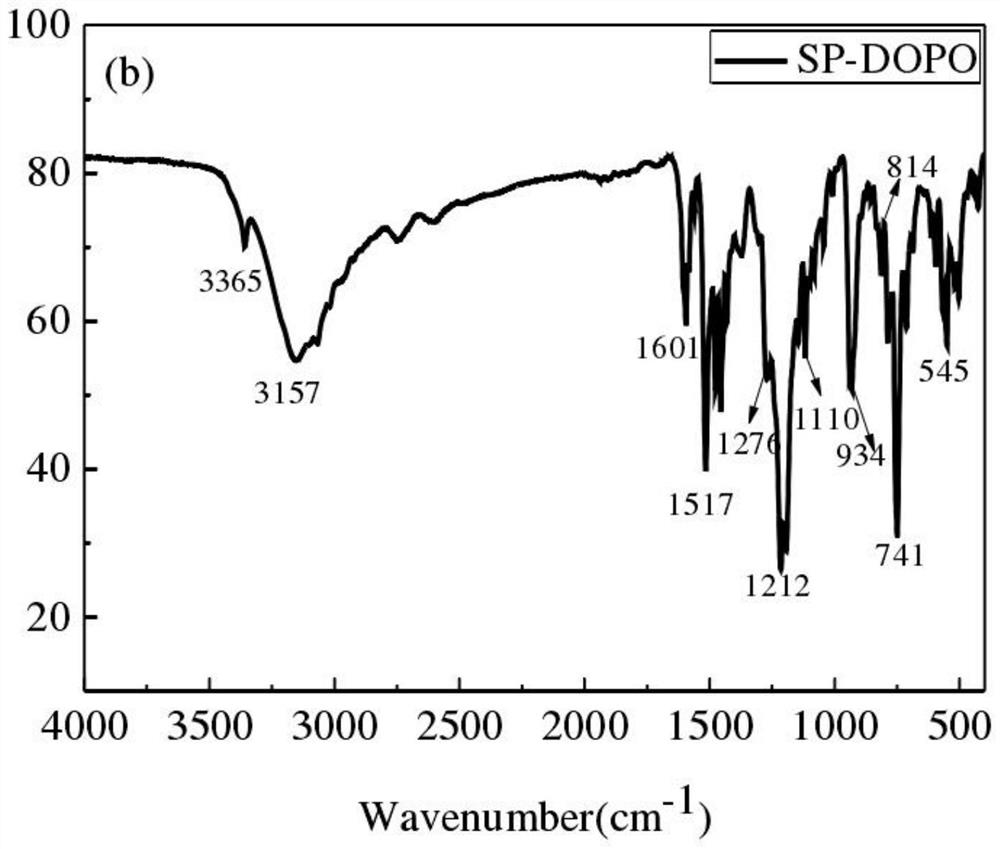

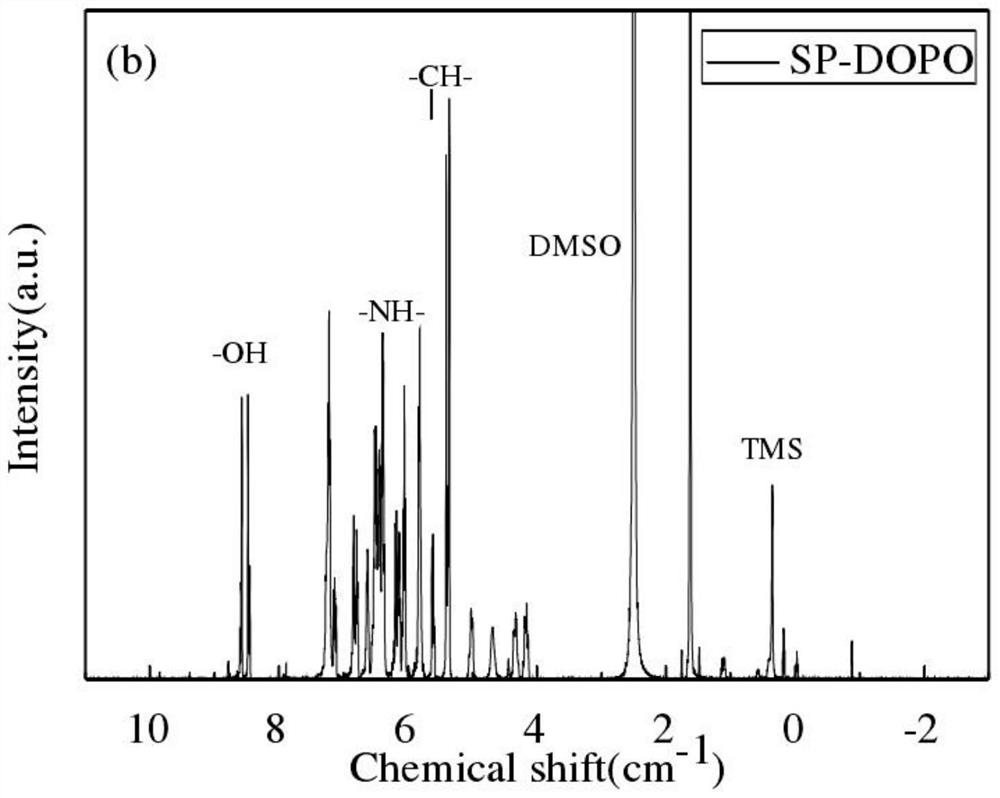

[0020] Specific embodiment one: this embodiment is a phosphorus nitrogen synergistic flame retardant compound, and its structural formula is:

[0021]

specific Embodiment approach 2

[0022] Specific embodiment two: This embodiment is a method for preparing a phosphorus-nitrogen synergistic flame retardant compound, which is specifically completed in the following steps: firstly, dehydration and condensation of o-hydroxybenzaldehyde and p-phenylenediamine in absolute ethanol make an intermediate Imine SP, and then the intermediate imine SP and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide in anhydrous ethanol to obtain phosphorus and nitrogen synergistic flame retardancy agent compound.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the operation process of the dehydration condensation is as follows: stirring and reacting at a temperature of 50-70°C for 3h-7h. Others are the same as in the second embodiment.

[0024] The dehydration condensation product obtained in this embodiment is firstly cooled naturally, then suction-filtered and washed with absolute ethanol in sequence, and then dried at a temperature of 60-80°C for 24 hours to obtain the intermediate product imine SP, which is sealed in bags for later use.

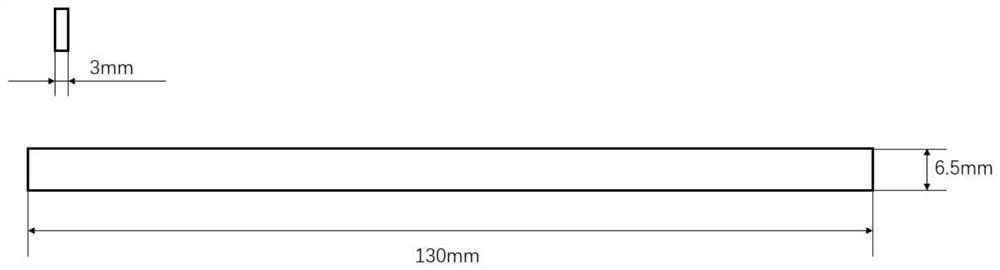

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com