Medical stone health pad and preparation method thereof

A medical stone and health care pad technology, applied in chemical instruments and methods, electrotherapy, phototherapy, etc., can solve the problems of unevenness, powder leakage layout, toxic coating materials, etc., to shield the body from harm, Low cost, solve the effect of uneven layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A medical stone health care pad, which includes an upper covering material, a medical stone filling, and a lower covering material from top to bottom, and the upper and lower covering materials are heat-sealed to seal the medical stone filling in the middle .

[0026] see figure 1 , the surface of the medical stone health care pad forms a grid shape that is not connected to each other, the upper and lower cladding materials are PVC materials, and the main component of the medical stone filling is medical stone powder.

[0027] The ingredients of the medical stone filling include medical stone powder, silica gel, negative ion powder, calcium saccharate, green mica powder, polypropylene nanofiber, potassium citrate, Sichuan Phellodendron powder, and the weight parts of the above components are medical stone powder 55- 65 parts, 20-25 parts of silica gel, 10-15 parts of negative ion powder, 2-3 parts of calcium saccharate, 1-1.5 parts of green mica powder, 5-10 parts of p...

Embodiment 2

[0030] As a further improvement, in addition to having the above-mentioned technical features, the preparation method of the medical stone health pad includes the following steps: a. Prepare the medical stone filling, and compress the mixed powder mainly composed of medical stone into the same size , the thickness of the disc; b. Place a grid mold on the table of the high-frequency heat sealing machine, spread the covering material on the upper layer of the grid mold, and place the pressed disc in the center according to the grid position; c. The disc is covered with a layer of upper coating material, and after being placed neatly, it is pressed by the head of a high-frequency heat-sealing machine. Once formed, the medical stone health care pad is obtained.

[0031] In step a, the mixed powder is pressed through a hydraulic tablet press, and the thickness of the pressed disc is 2-6mm, and the ideal thickness of the pressed disc is 4mm. Tests have shown that each raw material in...

Embodiment 3

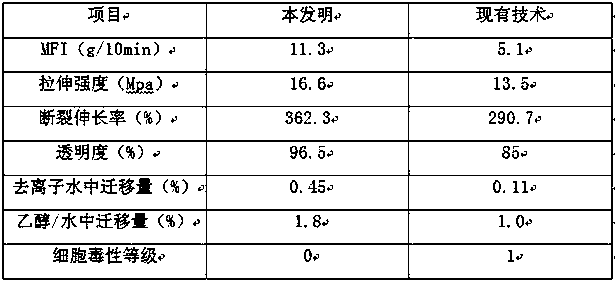

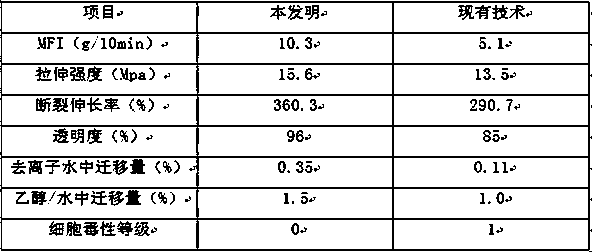

[0049] As a further improvement, in addition to having the above-mentioned technical features, the PVC material is prepared by the following method: ①add decaaldehyde and thiobisphenol into a container equipped with a stirrer, protect it with nitrogen, and stir at room temperature; ② After the barium zinc stabilizer, petrolatum and diacetyl epoxy vegetable glycerin are weighed, they are added to the container according to the proportion and stirred evenly, sealed and left for 8-15 hours, and then ground in the grinder for 3 times; ③ in the high-speed mixer Add PVC resin and the products in steps ① and ②, mix at high speed until the material temperature reaches 80-90°C, and then discharge to the planetary mixer; control the temperature of the planetary extruder at 130-140°C to make the PVC evenly plasticized and then enter In the plastic refining machine, the material of the plastic refining machine passes through a single-screw filter to filter impurities and is directly fed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com